Six Sigma vs. Design for Six Sigma (DFSS) Dr. Suresh C. Rama Senior Manager, Quality Systems Global Engine Manufacturing Alliance (GEMA) Dundee, MI

Suresh Rama Six Sigma vs DFSS Presentation for SME 01-10-06

Jan 20, 2015

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Six Sigma vs. Design for Six Sigma (DFSS)

Dr. Suresh C. RamaSenior Manager, Quality Systems

Global Engine Manufacturing Alliance (GEMA)

Dundee, MI

Presentation Overview

Introduction to Quality Defining Quality Measuring Quality

Six Sigma Method Tools

Design for Six Sigma Method Tools

Implementation Enablers Challenges

What are these companies have in common?

PROFITABILITY

QUALITY

CUSTOMER LOYALTY

INNOVATION

Defining Quality

A study asking Managers from 86 firms in the U.S. to define quality produced several responses including: Perfection Consistency Eliminating Waste Speed of Delivery Compliance to procedures, specifications, etc. Providing good and usable product Doing it right the first time Delighting or pleasing customers Total customer service and satisfaction

Extracted from “The Management and Control of Quality”, by Evans and Lindsay

Defining Quality

Quality is many things to many people in many parts of the organization

Quality can be defined based following criteria:1. Judgmental Criteria

Goodness/Excellence of a Product/Image2. Product-Based Criteria

The More the Better3. User-Based Criteria

Fitness for intended use4. Value-Based Criteria

Relationship to usefulness/satisfaction to price5. Manufacturing-Based Criteria

Conformance to specifications

Extracted from “The Management and Control of Quality”, by Evans and Lindsay

Integrating Perspectives on Quality

David Garvin’s 8 principle quality dimensions Performance Features Reliability Conformance Durability Serviceability Aesthetics Perceived Quality

Extracted from “The Management and Control of Quality”, by Evans and Lindsay

Quality as a Strategy

Competitive Advantage: Firm’s ability to achieve market superiority.

Wheelwright’s 6 characteristics for sustained competitive advantage:

1. Driven by Voice of the Customer2. Contributes to successful business3. Uses resources effectively4. Difficult for competitors to copy5. Basis for continuous improvement6. Motivates the entire organization

Does Quality play a role in any of these characteristics?

Extracted from “The Management and Control of Quality”, by Evans and Lindsay

Quality as a Strategy

Measuring Quality- Quality and Sigma

“Quality” is the degree of excellence of a product, process or service from the customer’s viewpoint

Virtually every activity has variation - if the outcome is too far from the target value (beyond a specification limit), a defect occurs

Standard deviation, , is a measure of variation from the target

Sigma Level, Z, of a process is:

(Spec Limit - Target) Z =

Std Dev Sigma Level measures the probability of achieving

a defect-free outcome

TargetUpper Spec

LimitLower Spec

Limit

Defects Defects

3Sigma Level = 3

• Common definition: 3.4 defects / million opportunities

• Applicability: All business processes (Manufacturing , IT, Finance, Marketing)

Allowable Process Mean Shifts with time

(±1.5from Design Target)

6

Upper Specification

Limit

Lower Specification

Limit

DesignTarget

** Waste due to additional inspection, tests, rework, scrap, customer dissatisfaction, etc. (Source: “Six Sigma” by Mikel Harry)

What is 6 Sigma?

• GenericSigma Level Defects Per Million Cost % of Sales *

3 66,807 25 - 40%4 6,210 15 - 25%5 233 5 - 15%6 3.4 < 1%

Savings (3 to 4.7 Sigma): $250K per projectBenefits (4.7 to 6 Sigma): Greater market share

• Savings Realized **

– GE: $750M (‘98), $1.5B (‘99)

– Motorola: $800-$900M / year ($15B over 11 years)

– ABB: $900M / year

– Allied Signal: $500M (‘98), $600M (‘99)

* Waste due to additional inspection, tests, rework, scrap, customer dissatisfaction, etc.** Quoted savings from the book “Six Sigma” by Mikel Harry & Richard Schroeder; Allied Signal quote from Industry Week

Benefits of 6 Sigma

• Structured, data-driven problem-solving method– “DMAIC”: Define, Measure, Analyze, Improve, Control

– Based on statistics, process analysis and process control

• Developed by Motorola; used successfully by TI, AlliedSignal, GE, ...

• Goal: improve the quality of existing processes – Manufacturing, business transactions, etc

• Payoffs: – Internal productivity improvement (lean processes)

– Capacity gain (lean resource management)

Six Sigma: driver for cost savingsSix Sigma: driver for cost savings

The 6 Sigma Method of Quality Improvement

How does 6 sigma work?

1. Visualize and Develop a Goal2. Obtain a Coach/Mentor3. Set the right Metrics 4. Understand the relationships between influencing

factors (x)s and the effects/output (y)s. y = f(x)5. Create a standradized process that develops a

roadmap to the Goal6. Now identify and implement the right Tools

Implementing Tools without the right Process, Strategy and Goal

Y

• Output

• Effect

• Symptom

• Monitor

x’s

• Inputs

• Root Causes

• Problems

• Fix & Control

Output Y = f (Process Variables x1, x2, …, xn)

• Many quality approaches focus on inspecting and fixing outputs (e.g., products)

• Six Sigma focuses on fixing and controlling key process variables which cause output defects

The 6 Sigma Focus

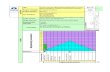

Process Improvements Plus Product Redesign to Match

Improved Process Capability

Time

SigmaLevel

6

5

4

3

Redesign Benefit

Process Improvements Only

“5 Wall”

Break through the “5 wall” by redesign for manufacturabilityBreak through the “5 wall” by redesign for manufacturability

The “5 Sigma Wall”

• It is difficult to apply classic Six Sigma to Engineering for new products– Engineering focuses on innovation, not process

improvement– Defect baselines not known for new, innovative designs

• And, most major new product quality problems are in performance and reliability, not manufacturability

• Engineering should focus on preventing problems • Need Six Sigma extension to new product creation

“Design for Six Sigma” - DFSS!

• Engineering should focus on preventing problems • Need Six Sigma extension to new product creation

“Design for Six Sigma” - DFSS!

Can 6 Sigma be applied to Engineering?

Minimize sensitivity to variation by choosing good nominal values for Xs

Minimize variation (sigma) by process capability improvement

212222

2211

/

... xxy

xxy

y

Traditional 6-Sigma - ReactiveTraditional 6-Sigma - Reactive

Design for Six Sigma - Proactive

Design for Six Sigma - Proactive

6 Sigma vs. Design for Six Sigma

What is Design For Six Sigma (DFSS)?

Design for Six Sigma (DFSS) is a strategy, a concept, a process and a set of tools

Strategy: To develop new and better products/processes to address the “voice of the customer”

Concept: To drive robust engineering (product & process) and validation with focus on “problem prevention.”

Process: To translate “voice of the customer” to engineering requirements and optimize the relationship between influencing factors and their effects on customers to achieve and sustain high quality levels.

Tools: Enablers for execution of the process to align with the “strategy.”

DFSS Strategy & Concept

DFSS

Process

DFSS

Tools

Customer Focus

ProactiveDesign Quality

To

• Quality “DESIGNED IN”

• Customer focused design requirements

• Disciplined and standardized design process

• Focus on system level designs and functions

• Performance predictions using analytical methods

• Designed up-front for robust performance & manufacturability

• Easier system integration

DFSS Reactive Design Quality

From

• Quality “TESTED IN”

• Evolving product design requirements

• Product team specific design process

• Focus on components and subsystems

• Performance assessment by “build and test”

• Performance & manufacturability problems fixed during and after launch

• Difficult system integration

DFSS Strategy: Revolutionize Design & Engineering

FIRE-FIGHTING

FIRE-PROOFING

D. F. S. S.

DFSS Process

Optim

ize

Design

Improve Efficiency

ReduceVariation

Out

put

Input

Improve Efficiency

ReduceVariation

Out

put

Input

Optimize Quality, Reliability and Durability and improve Robustness

Verify &

Valid

ate

Verify predictedQuality and Reliability

Develop Concepts

Develop, select and synthesize concepts

for better designsId

enti

fy

Op

po

rtu

nit

y

Select Projects based on Quality indicators

and gap to targets

Defin

e

Require

men

ts

Translate Voice of the Customer to Design Requirements

Key DFSS Tools

Capture Voice of Customer & Define Eng. Requirements Wants & needs tools Customer use observations Kano Analysis Quality Function Deployment

(QFD)Develop Concepts and Select

Pugh Matrix Axiomatic Design TRIZ Failure Mode & Effects Analysis

(FMEA)

Capture Voice of Customer & Define Eng. Requirements Wants & needs tools Customer use observations Kano Analysis Quality Function Deployment

(QFD)Develop Concepts and Select

Pugh Matrix Axiomatic Design TRIZ Failure Mode & Effects Analysis

(FMEA)

Develop Detailed Design Systems Engineering Function Models & FMEAs Transfer Functions

Statistical Design Monte Carlo Analysis

Design for Robust Performance Design of Experiments Robust Design Design for Reliability

Design for Manufacturability Process Capability Databases Statistical Tolerancing

Predict Quality DFSS Scorecards

Develop Detailed Design Systems Engineering Function Models & FMEAs Transfer Functions

Statistical Design Monte Carlo Analysis

Design for Robust Performance Design of Experiments Robust Design Design for Reliability

Design for Manufacturability Process Capability Databases Statistical Tolerancing

Predict Quality DFSS Scorecards

FMEA: Pro-Active Quality Tool

Purpose of a FMEA:

Risk Reduction to Customer(s) End user Manufacturing/Assembly Service

Risk Reduction to comply with or exceed Government Regulations Safety Regulatory

Rig

ht

Exe

cuti

on

Key Successful Factors for DFSS Implementation

1. Develop a strategy that fits the culture

2. Obtain true leadership from the top

3. Execute flawlessly (ownership & accountability)

4. Create a mentoring infrastructure (x-functional)

5. Communicate results early and often

6. Make it a way of doing business (integration)

Cultural

• Resistance to change: – “Why change our design

process?” – “We’re different” – “We already do that”

• Cost and disruption of training

• Fear that design cycle times will be longer, costs higher

• Integrating DFSS with existing development processes

Technical

• Paradigm change– Statistical versus

deterministic

• New methods and tools– Systems engineering– Design of experiments– Robust design – Design for reliability – Statistical tolerancing– Multi-variable optimization– ...

Leadership must overcome themLeadership must overcome them

Implementation Challenges

Message from Leadership

DFSS must become a religion Be an embodiment of 6 sigma (be competent) Radiate (train and spread) DFSS into every

business/organization Be a lunatic on the subject (drive it hard) Conduct DFSS reviews in the field Set goals based on 6 sigma metrics You have my full support to be outrageous on

this issue

Remember?

What are these companies have in common?

All of them use Design for Six Sigma - effectively

Making Six Sigma/DFSS Successful

Leadership from the top is crucial

Clearly communicate the Quality vision Demand Quality Drive discipline

Drive Quality by measurable, “stretch” goals Alignment of employee goals to organization’s goals Six Sigma & DFSS are not a “cure-all” for Quality by themselves

Involve everyone Don’t leave Quality to “quality specialists and professionals” Train everyone in basic Six Sigma/DFSS competence

Regard Quality as a cultural change, not just a toolset Make Quality a part of the organization’s DNA

THANK YOU!

Related Documents