Reciprocating compressor and pumps

Sep 12, 2014

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

ThermodynamicsThermodynamicsThermodynamics is the study of

the effects of work, heat, and energy on a system.

Thermodynamics is only concerned with macroscopic (large-scale)µscopic changes and observations

The Laws of Thermodynamics: The Laws of Thermodynamics: SummarySummary

Zeroth Law If two systems are each in thermal

equilibrium with a third, they are also in thermal equilibrium with each other.

First Law The increase in internal energy of a closed

system is equal to the difference of the heat supplied to the system and the work done by it: ΔU = Q - W

Second Law Heat cannot spontaneously flow from a

colder location to a hotter location.Third Law The entropy of all systems and of all states of a system is smallest at absolute zero 3

Thermodynamic Systems Thermodynamic Systems

5

Thermodynamic Processes Thermodynamic Processes Isobaric process : the pressure is constant.

Isochoric process : the volume is constant.

Isothermal process :the temperature is constant.

Adiabatic process : no heat enters or leaves the

system; i.e. Q = 0.

Isentropic process : the entropy is constant. It is also

known as reversible adiabatic process.

Isenthalpic Process: occurs at a constant Enthalpy

6

The Ideal Gas LawThe Ideal Gas Law Ideal gas law : PV = mRT or Pv = RT, where m is the no. of kmoles, v is the volume per kmole, T is the absolute

temperature in K, and the gas constant R = 8.314 x 103 J/(K.kmol). For a constant quantity of gas, P1V1/T1 = P2V2/T2.

Avogadro's law : For a given mass of an ideal gas, the volume and amount (moles n) of the gas are directly proportional if the temperature and pressure are constant. V is proportional to moles n

v/n=k

PP PP VV

VV

T increasingT increasing

TT TT

V increasingV increasingP increasingP increasing

The energy balance for a The energy balance for a steady-flow device (nozzle, steady-flow device (nozzle, compressor, turbine and pump) compressor, turbine and pump) with one inlet and one exit is:with one inlet and one exit is:

Fluid Moving EquipmentFluid Moving Equipment

Fluids are moved through flow systems using compressors, pumps, fans and blowers. Such devices increase the mechanical energy of the fluid. The additional energy can be used to increase

• Velocity (flow rate)• Pressure• Elevation

CASCASCOMPONENT Intake Air Filters : Prevent dust and atmospheric impurities from entering

compressor. Dust causes sticking valves, scored cylinders, excessive wear etc.

Compressor : Pressurizes the air Inter-stage Coolers : Reduce the temperature of the air (gas) before it

enters the next stage to reduce the work of compression and increase efficiency. They can be water-or air-cooled.

After Coolers : Reduce the temperature of the discharge air, and thereby reduce the moisture carrying capacity of air.

Air-dryers : Air dryers are used to remove moisture, as air for instrument and pneumatic equipment needs to be relatively free of any moisture. The moisture is removed by suing adsorbents or refrigerant dryers, or state of the art heatless dryers.

Moisture Traps : Air traps are used for removal of moisture in the compressed air distribution lines. They resemble steam traps wherein the air is trapped and moisture is removed.

Receivers : Depending on the system requirements, one or more air receivers are generally provided to reduce output pulsations and pressure variations.

Parts of reciprocating Parts of reciprocating CompressorCompressor

COMPRESSORCOMPRESSORWhat is Compressor? A compressor is a device that pressurize a

working fluid, one of the basic aim of compressor is to compress the fluid and deliver it to a pressure which is higher than its original pressure.

PURPOSE To provide air for combustion To transport process fluid through pipeline To provide compressed air for diving pneumatic

tools To circulate process fluid through certain

process

Types of compressor

Type ofcompressor

Positivedisplacement Dynamic

Reciprocating Rotary Centrifugal Axial

CompressorCompressor selection selection

Capacity of compressorCapacity of compressorCapacity of Compressor basically

indicated by following two parameter

1.Pressure2.FAD

What is FAD- What is FAD- Capacity of a Capacity of a Compressor?Compressor?

The FAD is the volume of air drawn into a compressor from the atmosphere. After compression and cooling the air is returned to the original temperature but it is at high pressure

Suppose atmospheric condition are Pa Ta and Va(the FAD) and the compressed condition are p , V and T

Some definationsSome definations Bore = Cylinder diameter. Stroke = Distance through which the piston moves. The two extreme positions of the piston are known as

head-end and crank-end dead centers. Clearance Volume (Cl) : Volume occupied by the fluid

when the piston is at head-end dead centre. Piston Displacement (PD) : Volume, a piston sweeps

through. Compression Ratio (rv) : Ratio of cylinder volume with

the piston at crank-end dead centre to the cylinder volume with the piston at head-end dead centre.

Mechanical Efficiency : which gives an indication of the

losses occurring between the piston and driving shaft.

CompressorCompressor Efficiency Efficiency DefinitionsDefinitions

I s o t h e r m a l E f f i c i e n c y

I s o t h e r m a l E f f i c i e n c y =A c t u a l m e a s u r e d i n p u t p o w e r

I s o t h e r m a l P o w e r

I s o t h e r m a l p o w e r ( k W ) = P 1 x Q 1 x l o g e r / 3 6 . 7 P 1 = A b s o l u t e i n t a k e p r e s s u r e k g / c m 2 Q 1 = F r e e a i r d e l i v e r e d m 3 / h r . r = P r e s s u r e r a t i o P 2 / P 1

CompressorCompressor Efficiency Efficiency DefinitionsDefinitions

V o l u m e t r i c E f f i c i e n c y 3F r e e a i r d e l i v e r e d m / m i nV o l u m e t r i c e f f i c i e n c y =

C o m p r e s s o r d i s p l a c e m e n t

C o m p r e s s o r D i s p l a c e m e n t = x D 2 x L x S x x n

4 D = C y l i n d e r b o r e , m e t r e L = C y l i n d e r s t r o k e , m e t r e S = C o m p r e s s o r s p e e d r p m = 1 f o r s i n g l e a c t i n g a n d 2 f o r d o u b l e a c t i n g c y l i n d e r s n = N o . o f c y l i n d e r s

Reciprocating Reciprocating CompressorsCompressorsTypes 1. Single acting The working fluid compressed at

only one side of the piston2. Double acting

The working fluid compressed alternately on both sides of the piston.

Frame HN2T - 150NPFrame HN2T - 150NP1Frame

Assly.2Inner Head

Assly. (LP)3Cylinder

Assly. (LP)4Outer Head

Assly. (LP)5Inner Head

Assly. (HP)6Cylinder

Assly. (HP)7Outer Head

Assly. (HP)

Frame, Cross Slide, Crank shaft and Frame, Cross Slide, Crank shaft and Connecting rod assemblyConnecting rod assembly 1. Breather

22. Crosshead

23. Cross Head Nut

35. Connecting Rod

40.Big End Bearing

36. Connecting rod Bolt

28,29. Stud,Nut

Breather:Breather: A vent or valve to release A vent or valve to release pressurepressure or to allow air to move freely around or to allow air to move freely aroundsomething.something.Crosshead: Is a mechanism used in large and reciprocating compressors to eliminate sideways pressure on the piston.Connecting Rod: connects the piston to the crank or crankshaft. Together with the crank, they form a simple mechanism that converts reciprocating motion into rotating motion.

Crank CaseCrank Case42. Belt wheel13.Oil Seal Ring18. Gasket for

Cover Flywheel end

34. Crank Shaft25. Internal Circlip24. Cross Head Pin26.Cross Head Pin43. Oil Cooler8. Cover for Oil

Pump end41. Oil Pump

Assembly44.Oil filter12.Thrust washer

Oil Seal Ring Oil Seal Ring :It prevent the oil the:It prevent the oil the oil to flow further oil to flow further

Gasket: is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression.Circlip: It is a type of fastener or retaining ring consisting of a semiflexible metal ring with open ends which can be snapped into place, into a machined groove on adowel pin or other part to permit rotation but to prevent lateral movement. There are two basic types: Internal and external, referring to whether they are fitted into a bore or over a shaft.

Cross Head Pin : It connects the piston to the connecting rod and provides a bearing for the connecting rod to pivot upon as the piston moves.

Thrust washer: Thrust washers are long-wearing flat bearings in the shape of a washer that transmit and resolve axial forces in rotating mechanisms to keep components aligned along a shaft.

Crank Pin/Gudgeon Pin: Connects the

piston to the connecting rod and provides a bearing for the connecting rod to pivot upon as the piston moves

Piston PartsPiston Parts1.Piston

Assembly

2.Rider Ring

3.Piston Ring

4.Sleeve for piston

PistonPiston Ring: Piston rings, Ring: Piston rings, mounted on the pistons of mounted on the pistons of lubricated or non-lube (oil free) lubricated or non-lube (oil free) compressors, are designed to compressors, are designed to ensure that the gas is ensure that the gas is compressed and to provide a compressed and to provide a seal between the piston and the seal between the piston and the cylinder.cylinder.

Rider Ring:The function of rider rings, used mainly in oil free or mini-lube compressors, is to support or guide the piston and rod assembly and prevent contact between the piston and the cylinder (risk of seizure).

Working:Working:Reciprocating compressors

generally, employ piston-cylinder arrangement where displacement of piston in cylinder causes rise in pressure.

Sequence of operationSequence of operation

Ideal indicator diagramIdeal indicator diagram

The total work interaction The total work interaction per cycle :per cycle :

Chicago Pneumatic: For over a century Chicago Pneumatic: For over a century Chicago Pneumatic has represented Chicago Pneumatic has represented tough tools designed to make tough jobs tough tools designed to make tough jobs easier.easier.Way back in 1889 John W. Duntley realized that construction

workers in particular had a need for many tools that weren’t yet available. He founded Chicago Pneumatic Tool Company and set out on a lifelong mission to provide all types of industries and companies the tools necessary for their success.

Over the years Duntley grew the company through product innovation, always insisting on product quality and reliability.

Manufactures of air & gas compressors & pneumatic portable tools like grinders demolition tools, pumps vibrators, rammers hammers, etc.

Decades of innovation1901 Chicago Pneumatic Tool Company is incorporated, after

Duntley persuades young steel magnate Charles M. Schwabto invest in the company

1925 CP seals an agreement to manufacture the Benz diesel engine , used in various racing cars in Europe at the time.

1930s Chicago Pneumatic construction and mining equipment is used in the building of the

Lincoln Tunnel, New YorkTriborough Bridge, New YorkChicago subway systemBoulder Dam, ArizonaGrand Coulee Dam, WashingtonEight dams comprising the Tennessee Valley Authority flood control and power generation projectGolden Gate suspension bridge, San Francisco

1940s In response to war effort demands, CP develops the “hot dimpling machine,” a device that heats rivets to 1,000 degrees Fahrenheit1960s Chicago Pneumatic customizes tools for the production of new aircraft designs: the Boeing 737 and 747,1987 Atlas Copco acquires Chicago Pneumatic Tool Company

Chicago Pneumatic Chicago Pneumatic CompetitionCompetitionElgi EquipmentIngersoll randRevathi Cp

DefinitionDefinitionAn apparatus or machine for raising, driving, exha

usting fluid, by means of a piston, plunger, or set of rotating vanes

Principle of operation

Centrifugal force(throwing)

Positive displacement(physically pushing)

Type of PumpsType of Pumps

Classified by operating principle

Pump Classification

Dynamic Positive Displacement

Centrifugal Special effect Rotary Reciprocating

Internal gear

External gear Lobe Slide

vane

Others (e.g. Impulse, Buoyancy)

Pumps

Dynamic Positive Displacement

Centrifugal Special effect Rotary Reciprocating

Internal gear

External gear Lobe Slide

vane

Others (e.g. Impulse, Buoyancy)

Pumps

Centrifugal PumpsCentrifugal PumpsMost common type of pumping machinery. There are many types, sizes, and designs from various manufacturers who also publish operating characteristics of each pump in the form of performance (pump) curves. The device pictured on the cover page is a centrifugal pump.

Pump curves describe head delivered, pump efficiency, and net positive suction head (NPSH) for a properly operating specific model pump.

Centrifugal pumps are generally used where high flow rates and moderate head increases are required.

Terms to be familiar Terms to be familiar withwith

Impeller- transmit energy to pressure

Volute- water passes and pressure is increased

This machine consists of an IMPELLER rotating within a case (diffuser)

Liquid directed into the center of the rotating impeller is picked up by the impeller’s vanes and accelerated to a higher velocity by the rotation of the impeller and discharged by centrifugal force into the case (diffuser).

Centrifugal PumpsCentrifugal Pumps

Working principles Working principles centrifugal pumpscentrifugal pumps

Head is a term for expressing feet of water column

Head can also be converted to pressure

"Head""Head"

100 feet

43.3 PSI

Reservoir of Fluid

Pressure Gauge

HeadHeadHead and pressure are

interchangeable terms provided that they are expressed in their correct units.

The conversion of all pressure terms into units of equivalent head simplifies most pump calculations.

Conversion Factors Between Conversion Factors Between Head and PressureHead and Pressure

Head (feet of liquid) =Pressure in PSI x 2.31 / Sp. Gr.

Pressure in PSI = Head (in feet) x Sp. Gr. / 2.31

PSI is Pounds per Square InchSp. Gr. is Specific Gravity which for

water is equal to 1◦ For a fluid more dense than water, Sp.

Gr. is greater than 1◦ For a fluid less dense than water, Sp.

Gr. is less than 1

Diameter of the Impeller

Thickness of the impeller

Centrifugal ImpellersCentrifugal Impellers

Thicker the Impeller- More WaterLarger the DIAMETER - More PressureIncrease the Speed - More Water and

Pressure

Impeller Vanes

“Eye of the Impeller”Water Entrance

Two-Stage Centrifugal Two-Stage Centrifugal PumpsPumps

Two Impellers within a single housing◦ Allow delivery

in Volume(parallel) or Pressure (series)

Thrust balance in a multi-stage pump

Positive Displacement Positive Displacement PumpsPumpsTo move fluids positive displacement pumps admit a fixed volume of

liquid from the inlet into a chamber and eject it into the discharge. Positive displacement pumps are used when higher head increases are required. Generally they do not increase velocity.

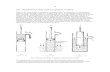

Reciprocating Pumps

• Piston type Vertical& Horizontal & double

acting• Plunger type

• Diaphragm pump

Reciprocating pumps

Explain double acting, plunger type , vertical, horizontal, multistage

Diaphragm pumps

Diaphragm Reciprocating pumps

Basic principle is similar to a reciprocating plunger pump/Plunger pressurizes the hydraulic oil which when pressurized pushes the diaphragm and discharge starts.Stroke length can be adjusted and hence the dosing flow rate.No direct contact of plunger with the solution.Direct contact is only with diaphragm ( neoprene, Teflon etc)

Dia

phra

gm R

ecip

roca

ting

pum

psFigure 1: The air valve directs pressurized air to the back side of diaphragm "A". The compressed air is applied directly to the liquid column separated by elastomeric diaphragms. The compressed air moves the diaphragm away from the center block of the pump. The opposite diaphragm is pulled in by the shaft connected to the pressurized diaphragm. Diaphragm "B" is now on its air exhaust stroke; air behind the diaphragm has been forced out to atmosphere through the exhaust port of the pump. The movement of diaphragm "B" toward the center block of the pump creates a vacuum within the chamber "B". Atmospheric pressure forces fluid into the inlet manifold forcing the inlet ball off its seat. Liquid is free to move past the inlet valve ball and fill the liquid chamber.

Dia

phra

gm R

ecip

roca

ting

pum

psFigure 2: When the pressurized diaphragm, diaphragm"A", reaches the limit of its discharge stroke, the air valve redirects pressurized air to the back side of diaphragm "B". The pressurized air forces diaphragm "B" away from the center block while pulling diaphragm "A" to the center block. Diaphragm "B" forces the inlet valve ball onto its seat due to the hydraulic forces developed. These same hydraulic forces lift the discharge valve ball, forcing fluid flow to flow through the pump discharge. The movement of diaphragm "A" to the center block of the pump creates a vacuum within liquid chamber "A". Atmospheric pressure forces fluid into the inlet manifold of the pump. The inlet valve ball is forced off its seat allowing the fluid being transferred to fill the liquid chamber.

Diaphragm Reciprocating pumps

Figure 3: Upon completion of the stroke, the air valve again redirects air to the back side of diaphragm "A", and starts diaphragm "B" on its air exhaust stroke. As the pump reaches its original starting point, each diaphragm has gone through one air exhaust or one fluid discharge stroke. This constitutes one complete pumping cycle. The pump may take several cycles to become completely primed depending on the conditions of the application.

Gear and screw pumps•High pressure and viscous fluids•Used in Samd for lube and seal oil pumps air booster of ammonia, 102-J

Gear pumps

•High pressure and viscous fluidsExample : lube/ seal oil pumps

See the solution is pushed out of the pump physically

Only one gear is used ( Explain)

Related Documents