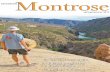

6400 RD 6450 RD HWY 550 CHIPETA RD PREPARED BY PROVIDENCE PREPARED FOR COVER SHEET, DRAWING LIST & VICINITY MAP 8 M. KAVANAUGH M. KAVANAUGH L. LINDEEN 1 G-001 SPRUCE POINT AIR INJECTION VAULT SCALE: VICINITY MAP NTS N PROVIDENCE PROJECT NO. 171005.01 INFRASTRUCTURE CONSULTANTS PROJECT SITE DESCRIPTION OF ISSUE / REVISION REVISION REVISED BY M. KAVANAUGH SPRUCE POINT AIR INJECTION VAULT DRAWING: SHEET: DRAWN BY: OF PROJECT: 171005.01 DESIGNER: APPROVED BY: DWG: S:\200 Projects\171005.01-Montrose Air Injection Station\900 CAD\02-SHEETS\G-001.DWG USER: mkavanaugh DATE: Oct 10, 2019 8:13pm XREFS: G-MAI-BD G-MAI-SUBMIT IMAGES: COBBLE CREEK.jpg VERIFY SCALE BAR IS ONE INCH ON ORIGINAL DRAWING IF NOT ONE INCH ON THIS SHEET, ADJUST SCALES ACCORDINGLY FINAL FOR BID PROVIDENCE INFRASTRUCTURE CONSULTANTS 4901 EAST DRY CREEK ROAD, SUITE 210 CENTENNIAL, CO 80122 TEL: (303)997-5035 www.providenceic.com 10/11/2019 CITY OF MONTROSE M O N T R O S E C O L O R A D O 10/11/19 FINAL FOR BID DRAWING LIST SHEET DRAWING DESCRIPTION 1 G-001 COVER SHEET, DRAWING LIST & VICINITY MAP 2 G-002 GENERAL NOTES 3 C-001 SITE PLAN 4 C-002 CIVIL DETAILS 5 P-001 VAULT PLAN 6 P-002 VAULT SECTION 7 I-001 P&ID LEGEND AND SYMBOLS 8 I-101 PROCESS & INSTRUMENTATION DIAGRAM N SCALE: LOCATION MAP NTS PROJECT LOCATION GREELEY NEBRASKA 70 76 KANSAS OKLAHOMA 25 WYOMING UTAH 70 NEW MEXICO STATE OF COLORADO ARIZONA DENVER 34 PUEBLO MONTROSE GRAND JUNCTION DURANGO TRINIDAD M O N T R O S E C O L O R A D O

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

6400 RD

6450

RD

HW

Y 550

CHIPETA RD

PREPARED BY

PROVIDENCE

PREPARED FOR

COVER SHEET, DRAWING LIST& VICINITY MAP 8

M. KAVANAUGHM. KAVANAUGH

L. LINDEEN1

G-001

SPRUCE POINT

AIR INJECTION VAULT

SCALE: VICINITY MAP

NTS

N

PROVIDENCE PROJECT NO. 171005.01

INFRASTRUCTURECONSULTANTS

PROJECT SITE

DESCRIPTION OF ISSUE / REVISIONREVISION REVISED BY

M. KAVANAUGHSPRUCE POINT

AIR INJECTION VAULT DRAWING:

SHEET:

DRAWN BY:

OF

PROJECT: 171005.01

DESIGNER:APPROVED BY:

DW

G:

S:\2

00 P

roje

cts\

1710

05.0

1-M

ontro

se A

ir In

ject

ion

Stat

ion\

900

CAD

\02-

SHEE

TS\G

-001

.DW

G

USE

R: m

kava

naug

hD

ATE:

Oct

10,

201

9 8

:13p

m

XR

EFS:

G-M

AI-B

D

G-M

AI-S

UBM

IT

IMAG

ES: C

OBB

LE C

REE

K.jp

g

VERIFY SCALEBAR IS ONE INCH ONORIGINAL DRAWING

IF NOT ONE INCH ON THISSHEET, ADJUST SCALES

ACCORDINGLYFINAL FOR BID

PROVIDENCE INFRASTRUCTURE CONSULTANTS4901 EAST DRY CREEK ROAD, SUITE 210CENTENNIAL, CO 80122TEL: (303)997-5035www.providenceic.com

10/11/2019

CITY OF MONTROSE

M

O

N

TROS

E

C

OLO

RA

D

O

10/11/19FINAL FOR BID

DRAWING LISTSHEET DRAWING DESCRIPTION1 G-001 COVER SHEET, DRAWING LIST & VICINITY MAP

2 G-002 GENERAL NOTES3 C-001 SITE PLAN4 C-002 CIVIL DETAILS5 P-001 VAULT PLAN6 P-002 VAULT SECTION7 I-001 P&ID LEGEND AND SYMBOLS8 I-101 PROCESS & INSTRUMENTATION DIAGRAM

NSCALE: LOCATION MAP

NTS

PROJECTLOCATION

GREELEY

NEBRASKA

70

76

KANSAS

OKLAHOMA

25

WYOMING

UTAH

70

NEW MEXICO

STATE OFCOLORADO

ARIZONA

DENVER34

PUEBLOMONTROSE

GRANDJUNCTION

DURANGO TRINIDAD

M

O

N

TR O S

E

C

OL O

R

A

D

O

AutoCAD SHX Text

o

GENERAL NOTES8

M. KAVANAUGHM. KAVANAUGH

L. LINDEEN2

G-002DESCRIPTION OF ISSUE / REVISIONREVISION REVISED BY

M. KAVANAUGHSPRUCE POINT

AIR INJECTION VAULT DRAWING:

SHEET:

DRAWN BY:

OF

PROJECT: 171005.01

DESIGNER:APPROVED BY:

DW

G:

S:\2

00 P

roje

cts\

1710

05.0

1-M

ontro

se A

ir In

ject

ion

Stat

ion\

900

CAD

\02-

SHEE

TS\G

-002

.DW

G

USE

R: m

kava

naug

hD

ATE:

Oct

10,

201

9 8

:13p

m

XR

EFS:

G-M

AI-B

D

G-M

AI-S

UBM

IT

IMAG

ES:

VERIFY SCALEBAR IS ONE INCH ONORIGINAL DRAWING

IF NOT ONE INCH ON THISSHEET, ADJUST SCALES

ACCORDINGLYFINAL FOR BID

PROVIDENCE INFRASTRUCTURE CONSULTANTS4901 EAST DRY CREEK ROAD, SUITE 210CENTENNIAL, CO 80122TEL: (303)997-5035www.providenceic.com

10/11/2019

CITY OF MONTROSE

M

O

N

TROS

E

C

OLO

RA

D

O

10/11/19FINAL FOR BID

GENERAL CONDITIONS & PRE-CONSTRUCTION NOTES:

2. THE CONCRETE SHALL MEET THE FOLLOWING:a. CONFORM TO ASTM C94b. PORTLAND CEMENT, ASTM C150, TYPE IIc. CEMENT: MAXIMUM TRICALCIUM ALUMINATE SHALL NOT EXCEED 8%.

THE MAXIMUM PERCENT ALKALIES SHALL NOT EXCEED 0.6%d. WATER SHALL CONFORM TO THE REQUIREMENTS OF ASTM C94e. AGGREGATES SHALL CONFORM TO THE REQUIREMENTS OF ASTM C33f. AGGREGATE SIZE SHALL BE 3/4” MAXIMUMg. FINE AGGREGATE SHALL CONSIST OF SANDh. COARSE AGGREGATE SHALL BE WELL GRADED CRUSHED STONE,

NATURAL ROCKi. AGGREGATES SHALL BE FREE FROM ANY SUBSTANCES THAT WILL

REACT WITH THE CEMENT ALKALIS, AS DETERMINED BY APPENDIX X-1OF ASTM C33

j. COMBINED AGGREGATE GRADING SHALL BE AGGREGATE GRADE 67 PERASTM C33

k. DO NOT USE ANY ADMIXTURE THAT CONTAINS CHLORIDESl. WATER-REDUCING ADMIXTURES ARE PERMITTEDm. ACCELERATING ADMIXTURES SHALL NOT BE USEDn. ADMIXTURES USED SHALL BE COMPATIBLE WITH EACH OTHER AND THE

AGGREGATES

3. CONCRETE WORK SHALL CONFORM TO ACI 301, ACI 318, AND ACI 350

4. CONFORM TO ACI 305R & ACI 306 FOR PLACING CONCRETE DURING HOTOR COLD WEATHER, RESPECTIVELY.

5. CONCRETE SHALL BE BATCHED, MIXED, AND TRANSPORTED INACCORDANCE WITH ACI 301. EACH TRUCK SHALL HAVE A TICKET SHOWINGACTUAL BATCH WEIGHTS OF MATERIALS IN ADDITION TO THE MAXIMUMAMOUNT OF WATER WHICH MAY BE ADDED AT THE SITE. THE TOTALWATER IN THE MIX AT THE TIME OF PLACING, INCLUDING WATER ADDED ATTHE SITE, SHALL NOT EXCEED THE AMOUNT PRE-APPROVED IN THE MIXDESIGN.

6. REINFORCEMENT STEEL SHALL BE DEFORMED BARS CONFORMING INQUALITY TO THE REQUIREMENTS OF ASTM A615 OR A706, GRADE 60.

7. ALL DETAILING, FABRICATION, AND PLACING OF REINFORCINGBARS, UNLESS OTHERWISE INDICATED, SHALL BE IN ACCORDANCE WITHACI-315, “MANUAL OF STANDARD PRACTICE FOR DETAILING REINFORCEDCONCRETE STRUCTURES”.

8. CONCRETE COVER FOR ALL REINFORCING BARS SHALL BE 3” UNLESSOTHERWISE NOTED.

9. SHOP DRAWINGS SHALL BE REQUIRED ON REINFORCING STEEL, ANDSHALL BE REVIEWED PRIOR TO FABRICATION.

10. DIMENSIONS ARE TO THE CENTERLINES OF THE BARS UNLESS SHOWNOTHERWISE.

11. CONFORM TO ACI 308 FOR CURING CONCRETE.

12. PROVIDE A MINIMUM OF FIVE CONCRETE TEST CYLINDERS FOR EACHPOUR. TEST CYLINDERS AS FOLLOWS: ONE AT SEVEN DAYS, TWO AT 28DAYS, ONE SITE-CURED, AND ONE RESERVE. SUBMIT TEST RESULTS TOTHE ENGINEER.

13. CONCRETE CYLINDER SAMPLING AND TESTING: CONFORM TO ASTMSPECIFICATIONS. ACCEPTANCE OF CONCRETE SHALL BE GOVERNED BYTHE PROVISIONS OF ACI 318 “BUILDING CODE REQUIREMENTS FORREINFORCED CONCRETE”. CONCRETE TESTING WILL BE PERFORMED BYINDEPENDENT TESTING AGENCY AT CONTRACTOR EXPENSE.

CONCRETE NOTES (CONTRACTOR):1. MIXES SHALL MEET OR EXCEED EACH REQUIREMENT SPECIFIED. WHERE

STRENGTH, MINIMUM CEMENT CONTENT, AND MAXIMUMWATER/CEMENTITIOUS MATERIAL RATIO ARE SPECIFIED, THE MOSTSTRINGENT SHALL APPLY. FOR EXAMPLE, A MAXIMUM WATER/CEMENTITIOUSRATIO MIGHT RESULT IN A STRENGTH GREATER THAN THE MINIMUMSPECIFIED. SUBMIT CONCRETE MIX DESIGNS FOR REVIEW.

MIXDESIGN

TYPEf c (PSI)

AT 28 DAYSMAX W/CM

RATIO

STRUCTURALCONCRETE

4,000 0.45

MIX DESIGN NOTES:1. FLY ASH SHALL NOT EXCEED 20% OF THE TOTAL CEMENTITIOUS CONTENT.2. MIXES CONTAINING WATER REDUCERS SHALL HAVE A MAXIMUM SLUMP OF 6".

MINIMUMCEMENTITIOUS

CONTENT (LB/YD3)(NOTE 1)

560

MAXIMUMSLUMP

(INCHES)(NOTE 2)

4

AIRENTRAINMENT

(%)

6

'

1. ALL SPECIFICATIONS, DRAWINGS, AND DETAILS INCLUDED IN THESE DRAWINGS SHALLFULLY APPLY TO THE WORK WHETHER SPECIFICALLY REFERENCED OR NOT.

2. THE CONTRACTOR SHALL COMPLY WITH ALL LOCAL, STATE, AND FEDERAL LAWS ANDREGULATIONS THAT ARE PERTINENT TO THIS WORK.

3. THE CONTRACTOR SHALL HAVE ONE SIGNED COPY OF THE APPROVED PLANS ANDSPECIFICATIONS AND ANY ADDITIONAL REQUIRED CITY OF MONTROSE OR MONTROSECOUNTY DESIGN STANDARDS AT THE JOB SITE AT ALL TIMES.

4. CONTRACTOR SHALL OBTAIN, COORDINATE AND PAY FOR THE SERVICES OF QUALITYCONTROL TESTING FIRM(S) FOR ALL LABORATORY AND FIELD TESTING REQUIRED BYTHE SPECIFICATIONS.

5. ALL MATERIALS AND WORKMANSHIP SHALL BE SUBJECT TO INSPECTION BY THEOWNER OR ENGINEER. THE OWNER OR ENGINEER RESERVES THE RIGHT TO ACCEPTOR REJECT ANY SUCH MATERIALS AND WORKMANSHIP THAT DOES NOT CONFORM TOTHE STANDARDS AND SPECIFICATIONS SHOWN IN THE CONTRACT DOCUMENTS.

6. THE CONTRACTOR SHALL NOTIFY THE OWNER'S REPRESENTATIVE IMMEDIATELY OFANY FIELD CONDITION NOT CONSISTENT WITH THE CONSTRUCTION DOCUMENTS.

7. THE CONTRACTOR SHALL REFER TO THE CONTRACT DRAWINGS FOR DESCRIPTION OFMATERIALS REFERRED TO BY SIZE, CLASS, TYPE, DESCRIPTION, OR OTHERWISESPECIFIED ON THE DRAWINGS.

8. CONTACT THE ENGINEER'S OFFICE IMMEDIATELY IF ANY CONFLICTS ARISE DURINGTHE CONSTRUCTION OF ANY IMPROVEMENTS SHOWN ON THESE DRAWINGS.

9. THE CONTRACTOR SHALL REVIEW THE SITE TO DETERMINE EXISTING CONDITIONSAND ANYTHING NOT SHOWN ON THESE DRAWINGS SHALL BE BROUGHT TO THEATTENTION OF THE ENGINEER AND SHALL NOT CONSTITUTE AN EXTRA, UNLESSAPPROVED BY THE ENGINEER.

10. PRIOR TO CONSTRUCTION THE CONTRACTOR SHALL BE SOLELY RESPONSIBLE FOROBTAINING ALL NECESSARY CONSTRUCTION PERMITS FROM LOCAL, CITY, COUNTYAND STATE JURISDICTIONS FOR ALL ASPECTS OF THE WORK (UNLESS OTHERWISEDESIGNATED IN THE SPECIFICATIONS).

11. THESE PLANS DO NOT EXTEND TO OR INCLUDE DESIGNS OR SYSTEMS PERTAINING TOTHE SAFETY OF THE CONTRACTOR OR ITS EMPLOYEES, AGENTS, SUBCONTRACTORS,OR REPRESENTATIVES IN THE PERFORMANCE OF THE WORK. THE SEAL OF THEREGISTERED PROFESSIONAL ENGINEER(S) HEREON DOES NOT EXTEND TO ANY SUCHSAFETY SYSTEMS THAT NOW OR HEREAFTER MAY BE INCORPORATED IN THE WORK.

12. THE CONTRACTOR SHALL BE SOLELY AND COMPLETELY RESPONSIBLE FOR THECONDITIONS AT AND ADJACENT TO THE JOB SITE, INCLUDING SAFETY OF ALLPERSONS AND PROPERTY, DURING THE PERFORMANCE OF THE WORK. THISREQUIREMENT SHALL APPLY CONTINUOUSLY AND SHALL NOT BE LIMITED TO NORMALWORKING HOURS. THE DUTY OF THE OWNERS TO CONDUCT CONSTRUCTION REVIEWOF THE CONTRACTOR'S PERFORMANCE IS NOT INTENDED TO INCLUDE REVIEW OFTHE ADEQUACY OF THE CONTRACTOR'S SAFETY MEASURES IN OR NEAR THECONSTRUCTION SITE.

13. ALL CONSTRUCTION OPERATIONS SHALL BE ACCOMPLISHED IN ACCORDANCE WITHAPPLICABLE REGULATIONS OF THE U.S. OCCUPATIONAL SAFETY AND HEALTHADMINISTRATION

14. ANY CONSTRUCTION DEBRIS OR MUD TRACKING ONTO THE PUBLIC RIGHT-OF-WAY,RESULTING FROM THE PROJECT, SHALL BE IMMEDIATELY REMOVED BY THECONTRACTOR. THE CONTRACTOR SHALL IMMEDIATELY FIX ANY EXCAVATION, ORPAVEMENT FAILURE CAUSED BY THE PROJECT, AND SHALL PROPERLY BARRICADEANY OPEN UTILITY TRENCHES OR CONSTRUCTION AREAS.

15. WASTE MATERIAL PRODUCED AS A RESULT OF THE CONTRACTOR'S OPERATIONSSHALL BECOME THE PROPERTY OF THE CONTRACTOR AND SHALL BE DISPOSED OFOFF THE PROJECT SITE AT THE CONTRACTOR'S EXPENSE.

1. OWNER: THE OWNER FOR THE PROJECT SHALL BE THE CITY OF MONTROSE,COLORADO.

2. CONTRACTOR: THIS SHALL BE THE INSTALLATION CONTRACTOR FOR THE AIRINJECTION VAULT. THIS MAY EITHER BE A LOCAL CONTRACTOR HIRED BY THE OWNEROR THE OWNER ITSELF MAY FUNCTION AS THE CONTRACTOR.

3. SUPPLIER: THIS SHALL BE THE COMPANY PROVIDING THE PRE-MANUFACTURED AIRINJECTION VAULT AS A COMPLETE UNIT.

4. ENGINEER: THE ENGINEER FOR THIS PROJECT SHALL BE PROVIDENCEINFRASTRUCTURE CONSULTANTS, INC. 300 PLAZA DRIVE, SUITE 320, HIGHLANDSRANCH, CO 80129. PHONE NUMBER 303-997-5035.

DEFINITIONS:

1. AIR INJECTION VAULT SUPPLIER SHALL PROVIDE A COMPLETE PRE-ASSEMBLED UNITFROM THE FACTORY READY FOR PLACEMENT ON THE CONCRETE SLAB AT THEPROJECT SITE.

2. SUPPLIER SHALL COORDINATE DESIGN OF AIR INJECTION COMPONENTS AND VAULTINTERIOR HVAC, ELECTRICAL AND CONTROLS AND SHALL LOCATE COMPONENTS INACCESSIBLE AREAS.

3. JOBSITE INSTALLATION SHALL BE LIMITED TO EXTERIOR ELECTRICAL AND PIPINGCONNECTIONS. NO INTERNAL INSTALLATION OF EQUIPMENT, ELECTRICAL PANELS,WIRING OR APPURTENANCES WILL BE ALLOWED AT THE PROJECT SITE.

4. SUPPLIER SHALL PROVIDE SHIPPING TO THE PROJECT SITE. THE CONTRACTOR WILLPROVIDE A CRANE FOR UNLOADING THE VAULT FROM THE DELIVERY TRUCK TO THECONCRETE FOUNDATION SLAB.

5. SUPPLIER SHALL PROVIDE COMPLETE SHOP DRAWINGS TO THE ENGINEER FORAPPROVAL PRIOR TO THE START OF FABRICATION. SHOP DRAWINGS SHALL CONSISTOF FABRICATION DRAWINGS, DESIGN CALCULATIONS, ELECTRICAL ON-LINEDRAWINGS, ELECTRICAL SCHEMATICS AND AND CONTROL DIAGRAMS.

6. SUPPLIER SHALL PROVIDE ONE DAY OF STARTUP ASSISTANCE, COMMISSIONING ANDFACTORY TRAINING UPON START UP TO INCLUDE ONE REPRESENTATIVE OFSUPPLIER AND ONE REPRESENTATIVE OF AIR PUMP VENDOR. TRAVEL TIME SHALLNOT BE INCLUDED, REPRESENTATIVES SHALL ARRIVE THE PRIOR DAY AND BE READYTO START ON THE MORNING OF THE AGREED UPON STARTUP DATE.

7. PROVIDE ALL EQUIPMENT IN THE INTERIOR OF THE VAULT AS SHOWN ON THESEDRAWINGS. WHERE NAMES OF EQUIPMENT ARE USED, THAT NAMED ITEM OR ANENGINEER APPROVED EQUAL ARE ACCEPTABLE. “OR EQUAL” SUBSTITUTIONS MUSTBE SHOWN ON THE SHOP DRAWINGS AND APPROVED BY THE ENGINEER PRIOR TOFACTORY INSTALLATION.

8. SUPPLIER IS RESPONSIBLE FOR THE CARE OF THE VAULT UNTIL IT IS REMOVED FROMTHE DELIVERY TRUCK DURING UNLOADING.

AIR INJECTION VAULT GENERAL REQUIREMENTS (SUPPLIER):

INSTALLATION INSTRUCTIONS (CONTRACTOR/SUPPLIER):1. CONTRACTOR SHALL FULLY COMPLY WITH ALL INSTALLATION INSTRUCTIONS

PROVIDED BY THE SUPPLIER.

2. CONTRACTOR SHALL INSTALL PIPING AND ELECTRICAL CONNECTIONS FROM THE AIRINJECTION VAULT TO THE CONNECTION POINTS SHOWN ON THE DRAWINGS.

3. ELECTRICAL POWER SUPPLY SHALL BE FROM THE TRANSFORMER AT THE LIFTSTATION. CONTRACTOR SHALL PROVIDE ALL MATERIAL AND DISCONNECTS PER THENATIONAL ELECTRICAL CODE.

4. THE VOLTAGE TO THE VAULT SHALL BE 3 PHASE, 230 VOLT. TOTAL ESTIMATEDAMPERAGE LOAD WILL BE PROVIDED BY THE SUPPLIER WITH THE SHOP DRAWINGS.

5. CONTRACTOR SHALL BE RESPONSIBLE FOR THE PHYSICAL PROTECTION AND ANYDAMAGE TO THE VAULT FROM THE REMOVAL FROM THE DELIVERY TRUCK TO THEACCEPTANCE OF THE INSTALLATION BY THE OWNER.

1. SUPPLIER SHALL PROVIDE STRUCTURAL DESIGN FOR THE BURIED STEEL VAULT ANDSHALL SUBMIT STRUCTURAL CALCULATIONS STAMPED BY A PROFESSIONALENGINEER FOR REVIEW.

2. VAULT IS NOT SUBJECT TO VEHICLE LOADING OVER THE TOP OF THE BURIED VAULT.SUPPLIER SHALL DESIGN STEEL STRUCTURE TO SUPPORT ALL OTHER ANTICIPATEDDEAD AND LIVE LOADS ASSOCIATED WITH NORMAL MAINTENANCE ACTIVITIES.

3. SUPPLIER SHALL DESIGN STRUCTURE TO RESIST BUOYANCY IN FULL-DEPTHSATURATED SOIL WITH A SAFETY FACTOR OF 1.5.

4. SUPPLIER SHALL DESIGN FOR ECONOMY OF VAULT SIZE. PRELIMINARY VAULT SIZINGOF 8-FOOT DIAMETER IS INTENDED AS A MAXIMUM.

5. SUPPLIER SHALL DESIGN INTEGRAL VAULT BASE ANCHOR PLATES FOR DRILLED,EPOXY-SET ANCHOR STUDS. PROVIDE PLATES IN NUMBER AND CONFIGURATIONDICTATED BY SUPPLIER'S DESIGN. INDICATE RECOMMENDED ANCHOR STUDDIAMETER ON SHOP DRAWING.

6. SUPPLIER SHALL DESIGN VAULT STRUCTURAL MEMBERS IN CONTACT WITH EARTH TOINCLUDE 0.10 INCHES OF SACRIFICIAL THICKNESS FOR CORROSION BEYOND THATTHICKNESS REQUIRED FOR STRUCTURAL INTEGRITY.

7. SUPPLIER SHALL PROVIDE A SINGLE MULTI-LAYER POWDER COATING SYSTEM FORALL FERROUS METAL SURFACES BOTH INTERIOR AND EXTERIOR.

8. SUPPLIER SHALL HOLIDAY TEST FACTORY COATING BOTH INTERIOR AND EXTERIORAND REPAIR HOLIDAYS WHERE IDENTIFIED IN ACCORDANCE WITH COATINGMANUFACTURER INSTRUCTIONS. SUBMIT PASSING HOLIDAY TEST FOR APPROVALPRIOR TO SHIPMENT.

9. SUPPLIER SHALL FURNISH TOUCH-UP PAINT FOR REPAIR OF COATING ON SITE BYCONTRACTOR.

10. SUPPLIER SHALL DESIGN A SACRIFICIAL GALVANIC ANODE SYSTEM WITH INTERNALVAULT TEST STATION FOR CORROSION PROTECTION OF STEEL VAULT.

AIR INJECTION VAULT STRUCTURE DESIGN REQUIREMENTS (SUPPLIER):

1. ENGINEER'S LAYOUT OF PROCESS COMPONENTS (EQUIPMENT AND PIPING) ISPRELIMINARY. SUPPLIER MAY DESIGN AIR INJECTION COMPONENT LAYOUT ASDESIRED IN CONCERT WITH REQUIREMENTS OF HVAC, ELECTRICAL AND OTHERAPPURTENANCES.

2. DEPICT ACTUAL PROPOSED EQUIPMENT DIMENSIONS AND CLEARANCES IN FINALSHOP DRAWING LAYOUT SUBMITTED FOR APPROVAL.

3. SUPPLIER SHALL PROVIDE DESIGN CALCULATIONS FOR AIR INJECTION EQUIPMENTSTAMPED BY A PROFESSIONAL ENGINEER. CALCULATIONS SHALL BE BASED UPONACTUAL PROPOSED COMPONENT AND PIPING CHARACTERISTICS AND GEOMETRYINDICATED IN THE SHOP DRAWINGS AND SHALL REPRESENT PRESSURE LOSS FROMCLAW PUMP DISCHARGE TO POINT OF AIR INJECTION. (SEE DESIGN CRITERIA ATINJECTION POINTS ON SHEET I-101)

4. SUPPLIER SHALL PROVIDE 316 STAINLESS STEEL AIR PIPING AND VALVES WITHINVAULT. INDICATE SELECTED SIZE ON SHOP DRAWINGS.

5. INCLUDE, AT A MINIMUM, THOSE ISOLATION VALVES AND DISASSEMBLY UNIONSSHOWN WHETHER ON PROCESS PLANS AND SECTIONS OR PROCESS ANDINSTRUMENTATION DIAGRAM FOR MAINTENANCE ACCESS.

6. AFTER INSTALLATION, NOISE FROM THE OPERATING AIR INJECTION VAULT SHALLNOT EXCEED 65 dBA AS MEASURED 50 FT FROM NEAREST VENT PIPE.

AIR INJECTION VAULT PROCESS DESIGN REQUIREMENTS (SUPPLIER):

AIR INJECTION VAULT ELECTRICAL DESIGN REQUIREMENTS (SUPPLIER):1. SUPPLIER SHALL PROVIDE DESIGN AND SIZING OF ALL ELECTRICAL COMPONENTS

AND WIRING REQUIRED TO SERVE THE VAULT IN ACCORDANCE WITH THE 2017NATIONAL ELECTRIC CODE.

2. SUPPLIER SHALL DESIGN AND FURNISH ALL ELECTRICAL EQUIPMENT ANDCOMPONENTS FROM SERVICE THROUGH ABOVE-GROUND MAIN VAULT DISCONNECT,POWER PANEL, VAULT INTERIOR DISCONNECT, VAULT EQUIPMENT AND CONTROLPOWER AND WIRING. CONTRACTOR SHALL FURNISH PLC/RTU AND PROGRAMMING.

3. COORDINATE ELECTRICAL DESIGN WITH REQUIREMENTS AND SPECIFICATIONS OFSUPPLIER FURNISHED EQUIPMENT.

4. ALL ELECTRICAL AND CONTROL WIRING INSIDE VAULT SHALL BE IN CONDUIT SIZEDTO CARRY THE CONDUCTORS IN ACCORDANCE WITH 2017 NEC.

5. SUPPLIER DESIGN SHALL INCLUDE CONDUIT PENETRATIONS AND CONNECTIONS FORELECTRICAL AND CONTROL WIRING CONDUIT AT VAULT EXTERIOR. CONDUIT SIZEAND NUMBER SHALL BE AS DETERMINED BY SUPPLIER DESIGN PLUS 1 SPARE OFEACH SIZE.

6. SUPPLIER SHALL TERMINATE ALL WIRING CONNECTIONS WITHIN THE VAULT AT THEFACTORY AND SHALL TEST INSTALLATION PRIOR TO SHIPPING.

7. PROVIDE AN ADDITIONAL 40 FEET OF CONTINUOUS CABLE AT VAULT EXTERIOR ONALL WIRES FOR CONTRACTOR TO CONNECT TO ABOVE GROUND ELECTRICAL ANDCONTROL EQUIPMENT.

8. SUPPLIER SHALL IDENTIFY ALL WIRES WITH IDENTICAL UNIQUE LABEL TAGS ON EACHEND FOR CONTRACTOR REFERENCE AND TERMINATION.

9. SUPPLIER SHALL DESIGN AND FURNISH VAULT LIGHTING.

AIR INJECTION VAULT HVAC DESIGN REQUIREMENTS (SUPPLIER):1. SUPPLIER SHALL DESIGN VAULT HVAC SYSTEMS TO PROVIDE CODE REQUIRED

VENTILATION FOR CLASSIFICATION AS NON-CONFINED SPACE ENTRY.

2. HVAC DESIGN SHALL BE CAPABLE OF MAINTAINING VAULT INTERIOR BETWEEN 60AND 80 DEGREES FAHRENHEIT DURING ALL SEASONS.

3. ACCOUNT FOR HEAT GENERATED BY EQUIPMENT AND HOT COMPRESSED AIR PIPING.PROVIDE PIPING INSULATION WHERE INDICATED.

4. PROVIDE ELECTRICAL UNIT HEATER AND EXHAUST FAN FOR PERIODS WHEN VAULTIS NOT OPERATING. AIR CONDITIONING SHALL NOT BE REQUIRED.

5. PROVIDE FAN AND LIGHT SWITCH AT HATCH ENTRY ACCESSIBLE FROM THE GROUNDSURFACE ABOVE.

AIR INJECTION VAULT CONTROL DESIGN REQUIREMENTS (SUPPLIER):1. SUPPLIER SHALL FURNISH AND INSTALL ALL CONTROL WIRING AND CONDUIT SHOWN

OR IMPLIED TO BE NECESSARY BY THESE DRAWINGS.

2. PROVIDE AN ADDITIONAL 40 FEET OF CONTINUOUS CABLE AT VAULT EXTERIOR ONALL WIRES FOR CONTRACTOR TO CONNECT TO ABOVE GROUND CONTROLEQUIPMENT.

3. ALL PROCESS CONTROL AND INTEGRATION PROGRAMMING SHALL BE FURNISHED BYCONTRACTOR.

4. SUPPLIER SHALL TERMINATE AND TEST ALL INTERNAL ELECTRICAL AND CONTROLWIRING AT THE FACTORY PRIOR TO SHIPMENT.

5. SUPPLIER SHALL IDENTIFY ALL WIRES WITH LABEL TAGS ON EACH END FORCONTRACTOR REFERENCE AND TERMINATION.

E

SS

8'' SS 8'' SS 8'' SS 8'' SS 8'' SS 8'' SS 8'' SS 8'' SS8'' FM 8'' FM 8'' FM 8'' FM 8'' FM 8'' FM 8'' FM

UG

EU

GE

UG

EU

GE

UG

E

UG

EU

GE

UG

EU

GE

UG

E

UG

EU

GE

UG

EU

GE

UG

E

E

OH

EO

HE

OH

EO

HE

OH

EO

HE

OH

EO

HE

OH

EO

HE

OH

EO

HE

OH

EO

HE

OH

E

GASGASGASGAS

GAS

GASGAS

GASGAS

GASGAS

GASGAS

GASGASGAS

GASGASGASGAS

WT

WT

WT

WT

WT

WT

WT

WT

WT

WT

WT

WT

WT

WT

WT

WT

WT

UG

E

UGE

UGE

UG

EU

GE

UGE

UG

E

UG

E

UG

E

X X X X X X

XX

XX

X

XXXXXXX

XX

X

6400

RO

AD

25.00' UTILITY EASEMENT10.00'

LIFT STATIONINV. 8" PVC GRAVITY SEWER = 5851.90TOP 8" SDR 21 FORCE MAIN = 5854.00INV. 8" PVC STUB OUT = 5851.63SUMP ELEV = 5846.18

EXISTINGELECTRICALPANEL

EXISTINGTRANSFORMER

5' DIA PRECASTMH, AIR INJECTIONTAP

20.0

0'

EXISTINGNATURAL GASGENERATOR

5861

5860

5861

5861

5863

5863

5861

5860

5860

5861

5860

5861

5862

5861

1.5" SCH 80 PVCMAIN AIRINJECTION LINE

1" DR21 PVC SUMPDRAIN LINE

1.5'

' AIR

1.5" SCH 80 PVCWETWELL AIRINJECTION LINE

3C-002

NEWELECTRICALPANEL

4C-002

1.5'' AIR 1.5'' AIR

1C-002

2C-002

GALVANICANODE BANK, BYSUPPLIER

22.50'

UTI

LITY

EASE

MEN

T

BEGIN NEW FENCE,MATCH EXISTINGCONSTRUCTION

END NEWFENCE

SITE PLAN8

M. KAVANAUGHM. KAVANAUGH

L. LINDEEN3

C-001DESCRIPTION OF ISSUE / REVISIONREVISION REVISED BY

M. KAVANAUGHSPRUCE POINT

AIR INJECTION VAULT DRAWING:

SHEET:

DRAWN BY:

OF

PROJECT: 171005.01

DESIGNER:APPROVED BY:

DW

G:

S:\2

00 P

roje

cts\

1710

05.0

1-M

ontro

se A

ir In

ject

ion

Stat

ion\

900

CAD

\02-

SHEE

TS\C

-001

.DW

G

USE

R: m

kava

naug

hD

ATE:

Oct

10,

201

9 8

:14p

m

XR

EFS:

G-M

AI-B

D

G-M

AI-S

UBM

IT

C-M

AI-S

P

C-M

AI-H

A

041

81B-

BA01

IM

AGES

:

VERIFY SCALEBAR IS ONE INCH ONORIGINAL DRAWING

IF NOT ONE INCH ON THISSHEET, ADJUST SCALES

ACCORDINGLYFINAL FOR BID

PROVIDENCE INFRASTRUCTURE CONSULTANTS4901 EAST DRY CREEK ROAD, SUITE 210CENTENNIAL, CO 80122TEL: (303)997-5035www.providenceic.com

10/11/2019

CITY OF MONTROSE

M

O

N

TROS

E

C

OLO

RA

D

O

10/11/19FINAL FOR BID

SCALE: SITE PLAN

1:8

LEGEND:EX BARBED WIRE FENCE

EX 8" SANITARY SEWER

EX 8" FORCEMAIN

EX WATER

EX OVERHEAD ELEC

EX GAS

EX UGE

AIR INJECTION LINE

DRAIN LINE

8'' SS

8'' FM

WT

OHE

GAS

UGE

1.5'' AIR

DR

N

EROSION CONTROL NOTES:1. ALL DRAINAGE PROTECTIVE DEVICES SUCH AS SWALES, INTERCEPTION DITCHES, PIPES, PROTECTIVE BERMS, CONCRETE CHANNELS, VEHICLE TRACTION PADS, OR

ANY OTHER MEASURES DESIGNED TO PROTECT IMPROVEMENTS, WHETHER EXISTING OR PROPOSED, FROM RUNOFF OR DAMAGE FROM STORM WATER, MUST BECONSTRUCTED PRIOR TO THE CONSTRUCTION OF ANY IMPROVEMENTS.

2. THE CONTRACTOR SHALL BE RESPONSIBLE FOR TEMPORARY EROSION CONTROL THROUGHOUT THE CONSTRUCTION DURATION AND SHALL INSTALL ALL REQUIREDEROSION CONTROL MEASURES AS NECESSARY AND CONSISTENT WITH APPLICABLE REGULATIONS.

3. TYPICAL STORMWATER AND SEDIMENT TRANSPORT BEST MANAGEMENT PRACTICES SHALL BE IMPLEMENTED AND MAINTAINED AS REQUIRED BY AUTHORITY HAVINGJURISDICTION.

SURVEY NOTES:1. PRESERVE ALL SURVEY MARKERS AND MONUMENTATION WHEREVER POSSIBLE. THOSE REQUIRING REMOVAL SHALL BE REESTABLISHED IN ACCORDANCE WITH THE

LOCAL GOVERNING AUTHORITY.

2. SITE SURVEY WAS PERFORMED BY DEL-MONT SURVEYING (970 249-2251) IN APRIL 2019. THE HORIZONTAL CONTROL IS BASED ON NORTH AMERICAN DATUM (NAD)1983 - COLORADO STATE PLANE CENTRAL. VERTICAL CONTROL IS BASED ON NORTH AMERICAN VERTICAL DATUM 1988.

3. CONTRACTOR SHALL USE A COLORADO PLS TO LAYOUT AND MARK THE LOCATION OF ALL CONSTRUCTED FACILITIES.

TEMPORARY CONTROLS:1. TRAFFIC CONTROL SHALL BE THE RESPONSIBILITY OF THE CONTRACTOR.

2. ALL BARRICADING AND TEMPORARY TRAFFIC CONTROL DEVICES OR METHODS USED DURING CONSTRUCTION SHALL BE IN ACCORDANCE WITH FEDERAL, STATE, ANDLOCAL STANDARDS. SUBMIT TRAFFIC CONTROL PLAN TO APPLICABLE AGENCIES AS REQUIRED AND OBTAIN PERMITS PRIOR TO CLOSURE OR DISRUPTION OF ANYROADS.

3. ALL REQUIRED UTILITIES FOR THE CONTRACTOR'S USE DURING CONSTRUCTION SHALL BE ARRANGED BY THE CONTRACTOR DIRECTLY WITH THE APPROPRIATEUTILITY AGENCY.

SURFACE RESTORATION NOTES:1. TRIM, TACK, AND MATCH EXISTING PAVEMENT THICKNESS WHERE DAMAGED.

2. RESTORE ALL AREAS DISTURBED BY CONSTRUCTION.

3. THE CONTRACTOR SHALL REPLACE ALL PAVING, STABILIZED EARTH, FENCES, DRIVEWAYS, SIDEWALKS, FIELD ROADS, ETC., WITH THE SAME TYPE OF MATERIALTHAT WAS REMOVED DURING CONSTRUCTION, AS DIRECTED BY THE ENGINEER, OR AS REFERENCED IN THE SPECIFICATIONS.

4. THE CONTRACTOR IS RESPONSIBLE FOR SAVING AND PROTECTING ALL EXISTING TREES AND VEGETATION WHERE REMOVAL FOR CONSTRUCTION IS NOT SPECIFIEDON THE DRAWINGS.

EXISTING UTILITY NOTES:1. COORDINATE UNDERGROUND UTILITY MARKINGS WITH EXISTING UTILITIES BY CONTACTING UTILITY NOTIFICATION CENTER OF COLORADO (1-800-922-1987) A

MINIMUM OF 72 HOURS PRIOR TO CONSTRUCTION OR GROUND DISTURBANCE IN ORDER TO OBTAIN LOCATES.

2. CONTRACTOR SHALL POTHOLE ALL EXISTING UTILITIES AND CONNECTIONS TO EXISTING FACILITIES THAT ARE LOCATED WITHIN 10 FEET OF THE PROPOSED AREALEXTENT OF EXCAVATION PRIOR TO STARTING CONSTRUCTION. CONTACT OWNER PRIOR TO POTHOLING IN AREAS NOT PLANNED TO BE DISTURBED DURINGCONSTRUCTION.

3. IT SHALL BE THE CONTRACTOR'S RESPONSIBILITY TO VERIFY LOCATIONS, ELEVATIONS, DIMENSIONS, TYPE AND CONDITION OF ADJACENT AND/OR CONFLICTINGUTILITIES IN ADVANCE OF CONSTRUCTION IN ORDER THAT ADJUSTMENTS CAN BE MADE TO PROVIDE ADEQUATE CLEARANCES AND/OR ALTERNATE CONNECTIONS,IF REQUIRED. THE CONTRACTOR SHALL PRESERVE AND PROTECT PUBLIC AND PRIVATE UTILITIES AT ALL TIMES DURING CONSTRUCTION. ANY DAMAGE TOUTILITIES RESULTING FROM THE CONTRACTOR'S OPERATIONS SHALL BE REPAIRED AND/OR RESTORED IN SUCH A MANNER AND CONDITION THAT IS ACCEPTABLETO THE ENGINEER, CITY AND AFFECTED UTILITY OWNER. THE CONTRACTOR SHALL PROMPTLY NOTIFY THE ENGINEER WHEN PROPOSED IMPROVEMENTS, GRADES,STRUCTURES OR UTILITIES CONFLICT WITH EXISTING STRUCTURES, GRADES OR UTILITIES.

4. THE CONTRACTOR SHALL CONTACT ALL UTILITY OWNERS FOR INSPECTION WHEN WORK IS SCHEDULED ADJACENT TO THE UTILITIES. THE CONTRACTOR ISRESPONSIBLE FOR PROTECTING AFFECTED UTILITIES IN ACCORDANCE WITH THE PLANS, SPECIFICATIONS, AND THE REQUIREMENTS OF THE OWNER. THECONTRACTOR SHALL BE RESPONSIBLE FOR ANY DAMAGE AND COSTS ASSOCIATED WITH INTERRUPTED OR LOST SERVICE DUE TO DAMAGE TO THESE UTILITIES.

5. REMOVE, REPLACE, OR RELOCATE ALL OVERHEAD INTERFERENCE WHICH MAY AFFECT CONTRACTOR'S OPERATION DURING CONSTRUCTION. AVOID DAMAGE TOSAME. USE EXTREME CAUTION WHEN WORKING NEAR OVERHEAD OR UNDERGROUND POWER, GAS, OR OTHER UTILITIES TO SAFELY PROTECT ALL PERSONNELAND EQUIPMENT. THE CONTRACTOR SHALL BE RESPONSIBLE FOR ALL COSTS AND LIABILITY IN CONNECTION WITH THIS WORK.

6. TAKE ALL PRECAUTIONS NECESSARY TO PROTECT EXISTING FACILITIES. ALL SUCH IMPROVEMENTS OR STRUCTURES DAMAGED BY THE CONTRACTOR'SOPERATIONS SHALL BE REPAIRED OR RECONSTRUCTED TO A NEW CONDITION AT THE CONTRACTOR'S EXPENSE.

STAGING AND ACCESS NOTES:1. THE CONTRACTOR SHALL PERFORM ALL WORK WITHIN THE LIMITS OF CONSTRUCTION AS SHOWN ON THE DRAWINGS AND DISCUSSED IN THE CONTRACT

DOCUMENTS. IF THE CONTRACTOR DAMAGES ANY EXISTING SITE OR PUBLIC AMENITIES (PAVEMENTS, CURBS, CURB AND GUTTER, SOD, TREES, FENCES, ETC.)OUTSIDE OR WITHIN EASEMENTS OR CONSTRUCTION LIMITS, THE CONTRACTOR SHALL REMOVE AND REPAIR SUCH TO THE SATISFACTION OF THE INDIVIDUALPROPERTY OWNERS AND THE ENGINEER.

2. THE CONTRACTOR SHALL UTILIZE SPACE WITHIN THE LIMITS OF CONSTRUCTION FOR STAGING AND TEMPORARY STORING OF MATERIALS. THE CONTRACTOR SHALLNOT ENCROACH UPON ANY PUBLIC, PRIVATE OR RIGHT-OF-WAY PROPERTY OUTSIDE THE LIMITS OF CONSTRUCTION.

3. EMERGENCY VEHICLE ACCESS SHALL BE MAINTAINED TO ALL PROPERTIES THROUGHOUT CONSTRUCTION.

4. THE CONSTRUCTION SITE SHALL ONLY BE ACCESSED FROM POINTS INDICATED ON THE DRAWINGS AND THE SITE SHALL ONLY BE ACCESSED FROM PUBLICRIGHT-OF-WAY THROUGH THE CONSTRUCTION LIMITS. THE CONTRACTOR MAY COORDINATE OTHERWISE WITH PROPERTY OWNERS AT ITS DISCRETION. COSTS FORDOING SO SHALL NOT BE BORNE BY THE OWNER. CONTRACTOR SHALL BE FULLY AND SOLELY LIABLE FOR ALL SUCH AGREEMENTS WITH PRIVATE PROPERTYOWNERS.

5. THE CONTRACTOR SHALL MAINTAIN ACCESS TO PUBLIC AND PRIVATE FACILITIES DURING CONSTRUCTION. ALL CONSTRUCTION ACTIVITIES SHALL BE COORDINATEDWITH THE OWNER.

AutoCAD SHX Text

G

AutoCAD SHX Text

p

1.5" WALL PENETRATIONW/ LINK SEAL

EL 5854.008" SDR 21 PVC

FORCE MAIN

8" PVC GRAVITY INLET

EL 5851.90

5846.18

3/4" PIPE SUPPORT

L 5855.00C

2-

1-

3/4" EPMD AIR HOSE

1.5x34" REDUCER

3/4" STRAIGHT CPLG EYE BOLT

LIFTING CHAIN

3/4" 316 SST PIPE

3/4" 316 SST QUICKDISCONNECT AIRFITTING

NPT HOSE ADAPTOR

6" 316 SST CL 125BLIND FLANGE

6" 316 SST BLINDFL W/ 3/4" TAP

EDI COARSEBUBBLE DIFFUSEROR EQUAL(TYP)3/4" 316 SST CROSS

3/4" EPDM HOSE

NEOPRENEFLANGE GASKET

PROVIDE 90° EYE BOLT ORFLANGE HARNESS LUG FORLIFTING CHAIN ATTACHMENT

3/4" 316 SST NIPPLE

3/4" 316 SST NIPPLE

1 12" WASHED ROCK FROMUNDISTURBED EARTH,VIBRATE TO COMPACT TO70% RELATIVE DENSITY

CONC GRADE RINGS

3" INSULATION

60"Ø PRECAST CONC MHSECTION FIELD VERIFYDEPTH

1 12" PVC BALL VALVE/ CORP STOP

NEW 1 12" TAP W/TAPPING SADDLE

#6 REBAR

60"Ø PRECASTFLAT MH COVER

SEAL ALL JOINTS

24"Ø MH RING AND COVERNEENAH, R-1510 OR EQUAL

3"

2"(TYP)

1 12" PVC CHECK VALVE

CORE PENETRATION &GROUT ANNULUS

8" DR21 PVC FORCE MAIN

1 12" SCH 80 PVC

NOTE: CONTRACTOR OPTION FOR USE OF ALTERNATIVE ENCLOSURESUCH AS HDPE METER PIT.

4" GALVANIZED POST (PROVIDEADDITIONAL VERTICALSUPPORTS AS REQUIRED)

CONDUITS (PERSUPPLIER DESIGN,CONTRACTORFURNISHED )

ADJUST SEPARATIONTO FIT WIDTH OFENCLOSURE

5'-6

" MAX

IMU

M

30" BELOWFINISHEDGRADE

CONCRETE 15" DIA

SERVICE DISCONNECT(SUPPLIER FURNISHED)

POWER PANEL (SUPPLIERFURNISHED) PLC/RTU (FURNISHED BY

CONTRACTOR)

CONDUITS(PER SUPPLIER DESIGN,CONTRACTOR FURNISHED)

FROM SITE SERVICE

TO VAULT

CIVIL DETAILS8

M. KAVANAUGHM. KAVANAUGH

L. LINDEEN4

C-002DESCRIPTION OF ISSUE / REVISIONREVISION REVISED BY

M. KAVANAUGHSPRUCE POINT

AIR INJECTION VAULT DRAWING:

SHEET:

DRAWN BY:

OF

PROJECT: 171005.01

DESIGNER:APPROVED BY:

DW

G:

S:\2

00 P

roje

cts\

1710

05.0

1-M

ontro

se A

ir In

ject

ion

Stat

ion\

900

CAD

\02-

SHEE

TS\C

-002

.dw

g

USE

R: m

kava

naug

hD

ATE:

Oct

10,

201

9 8

:14p

m

XR

EFS:

G-M

AI-B

D

G-M

AI-S

UBM

IT

C-M

AI-S

P

C-M

AI-H

A

041

81B-

BA01

IM

AGES

:

VERIFY SCALEBAR IS ONE INCH ONORIGINAL DRAWING

IF NOT ONE INCH ON THISSHEET, ADJUST SCALES

ACCORDINGLYFINAL FOR BID

PROVIDENCE INFRASTRUCTURE CONSULTANTS4901 EAST DRY CREEK ROAD, SUITE 210CENTENNIAL, CO 80122TEL: (303)997-5035www.providenceic.com

10/11/2019

CITY OF MONTROSE

M

O

N

TROS

E

C

OLO

RA

D

O

10/11/19FINAL FOR BID

SCALE: WETWELL DIFFUSER DETAIL

3"=1'-0"2- SCALE:

AIR INJECTION TAP MANHOLENTS

3-

SCALE: LIFT STATION WETWELL AERATION DETAIL

3/4"=1'-0"1-

SCALE: ELECTRICAL PANEL FRAME

NTS4-

25

12

12

4

10

9

3

28 29

30

1

18

27

14

9'-0

"

8'-0"6"

48"x60" HATCH(ABOVE)

22

1-1/2" PVCTO FORCE MAIN

AP-002

6"

9'-0"

BP-002

1-1/2" PVC TOWETWELL

9

12 107

8

8

15

7

9

9

10

9

1-1/2" x 1" PVCREDUCER (TYP)

35

30

13

CONCRETE BASE SLAB

INTAKE AIR VENT

EXHAUST AIR VENT

1" VAULT PENETRATION(TYP)

ACCESS LADDER

AIR INJECTION VAULT(8'-0" DIAMETER MAX.,NOTE 6)

VAULT PLAN8

M. KAVANAUGHM. KAVANAUGH

L. LINDEEN5

P-001DESCRIPTION OF ISSUE / REVISIONREVISION REVISED BY

M. KAVANAUGHSPRUCE POINT

AIR INJECTION VAULT DRAWING:

SHEET:

DRAWN BY:

OF

PROJECT: 171005.01

DESIGNER:APPROVED BY:

DW

G:

S:\2

00 P

roje

cts\

1710

05.0

1-M

ontro

se A

ir In

ject

ion

Stat

ion\

900

CAD

\02-

SHEE

TS\P

-001

.dw

g

USE

R: m

kava

naug

hD

ATE:

Oct

10,

201

9 8

:14p

m

XR

EFS:

G-M

AI-B

D

G-M

AI-S

UBM

IT

P-M

AI-V

AULT

PLA

N A

ND

SEC

TIO

NS_

1

IMAG

ES:

VERIFY SCALEBAR IS ONE INCH ONORIGINAL DRAWING

IF NOT ONE INCH ON THISSHEET, ADJUST SCALES

ACCORDINGLYFINAL FOR BID

PROVIDENCE INFRASTRUCTURE CONSULTANTS4901 EAST DRY CREEK ROAD, SUITE 210CENTENNIAL, CO 80122TEL: (303)997-5035www.providenceic.com

10/11/2019

CITY OF MONTROSE

M

O

N

TROS

E

C

OLO

RA

D

O

10/11/19FINAL FOR BID

SCALE: VAULT PLAN

1" = 1'-0"N

EQUIPMENT AND MATERIALS LISTID TAG NO. DESCRIPTION

1 P-101 10 HP CLAW PUMP, 3 PH, 230 V, 60 HZ, AIRTECH, BUSCH MINK, LEYBOLD OR APPROVED EQUAL

2 AC-101 AFTER COOLER W/ INTEGRAL FAN, 50 CFM CAPACITY MINIMUM, AKG OR EQUAL

3 P-102 1/2-HP SUMP PUMP W/ FLOAT SWITCH, 1 PH, 120 V, 60 HZ, ABS, ZOELLER OR EQUAL

4 1-1/4"x1" 316 STAINLESS STEEL (SST) UNION

5 1-1/4" 316 SST 90 DEGREE BEND

6 1-1/4" x 1" 316 SST REDUCER

7 1" 316 SST 45 DEGREE ELBOW

8 1" 316 SST TEE

9 1" 316 SST 90 DEGREE BEND

10 1" 316 SST UNION

11 1" SCH 40 316 SST PIPE

12 1" 316 SST BALL VALVE, FULL PORT, LEVER ACTUATED, TWO-PIECE, APOLLO 76F OR EQUAL

13 CK-101 1" 316 SST CHECK VALVE (IN-LINE SPRING TYPE), MAXIMUM CRACKING PRESSURE 0.50 PSI

14 CK-102 1" 316 SST CHECK VALVE (BALL TYPE), MAXIMUM CRACKING PRESSURE 0.50 PSI

15 CV-101, CV-102 1" 316 SST BALL VALVE, ELECTRICALLY ACTUATED, OPEN/CLOSE TYPE, DYNAQUIP OR EQUAL

16 SV-101 1/2" SOLENOID VALVE, NORMALLY CLOSED, 120 VAC, ASCO RED HAT OR EQUAL

17 SV-102 1/2" SOLENOID VALVE, NORMALLY CLOSED, 120 VAC, ASCO RED HAT OR EQUAL

18 4" AFTER COOLER EXHAUST DUCT

19 EF-101 EXHAUST FAN, IN-LINE DUCT TYPE, FANTECH, DAYTON, OR EQUAL

20 EXHAUST FAN DAMPER

21 LS-101 FLOAT SWITCH, SUMP PUMP ON/OFF CONTROL

22 LS-102 FLOOD SWITCH, GEMS LS-270 OR EQUAL

23 ANODE, TYPICAL OF 2

24 FE/FIT-101 1" THERMAL MASS AIR FLOW METER, SAGE PRIME SIP IN-LINE OR EQUAL

25 PI-101 PRESSURE GAUGE, 0-60 PSI, WIKA, ASHCROFT OR EQUAL

26 CK-103 3/4" CHECK VALVE, BALL TYPE

27 ALUMINUM LADDER

28 DS-101 LOCAL POWER DISCONNECT

29 TS-101 ANODE TEST STATION

30 1/2" 316 SST 45 DEGREE BEND

31 1/2" 316 SST 90 DEGREE BEND

32 1/2" 316 SST TEE

33 1/2" 316 SST BALL VALVE, FULL PORT, LEVER ACTUATED, TWO-PIECE, APOLLO 76F OR EQUAL

34 NV-101 1" 316 SST NEEDLE VALVE, SMITH COOPER S7166NV OR EQUAL

35 EUH-101 ELECTRIC UNIT HEATER, PER SUPPLIER DESIGN

NOTES:1. VAULT SUPPLIER SHALL SUBMIT AIR INJECTION BLOWER AND PIPING DESIGN FOR APPROVAL OF ENGINEER.

2. PROVIDE 12" THICK LAYER OF 1-1/2" ANGULAR, CRUSHED, WASHED ROCK STABILIZATION MATERIAL BENEATHFOUNDATION SLAB OF VAULT. VIBRATE TO COMPACT TO 70% RELATIVE DENSITY.

3. PLACE CONCRETE SLAB ON UNDISTURBED EARTH. IF UNSUITABLE MATERIAL IS FOUND AT BOTTOM OFEXCAVATION, IT SHALL BE REMOVED AND REPLACED WITH 1-1/2" CRUSHED ROCK STABILIZATION MATERIAL.

4. INSULATE ALL AIR PIPING TO PROTECT WORKERS FROM HIGH TEMPERATURE.

5. EXHAUST DUCT SHOWN OUT OF ROTATION IN THIS SECTION. SEE SHEET P-001 FOR LOCATION.

6. SUPPLIER'S DESIGN SHALL SEEK TO DECREASE OVERALL DIAMETER OF VAULT TO THE MAXIMUM EXTENTPRACTICAL FOR REMOVAL AND REPLACEMENT OF MAINTENANCE ITEMS.

7. SOME PIPING IS NOT SHOWN IN DETAIL. PROVIDE ALL PIPE AND FITTINGS REQUIRED TO COMPLETEINSTALLATION INCLUDING REDUCERS, BUSHINGS AND ANCILLARY MATERIALS REQUIRED FOR CONNECTION OFSUPPLIER ARRANGED EQUIPMENT LAYOUT.

1'-0

"

8

99

7

1

2

17

12

10

12

12

19

2018

16

7

25

8

23

#6 @ 12" O.C. EACHWAY, EACH FACE

4" VENT STACK W/INSECT SCREEN

BILCO HATCHOR APPROVEDEQUAL

7'-6

"

3230

1.5" PVC TOLIFT STATION

ANCHORTABS (TYP)

1'-0

"6"

LIGHT (TYP)

1'-0

"

1'-0"

6" INTAKE AIR VENTSTACK W/ INSECTSCREEN (TYP. OFEXHAUST)

UNDISTURBED EARTH (NOTE 3)

1-1/2" CRUSHED ROCK (NOTE 2)

10

8

SEE NOTE 4

3333

ACCESS LADDERW/ LADDER UP

11'-6

"±

12

15

34

10

14

15

1310

10

24

11

9 9

CV-102

CV-101 FE/FIT-101

9

7

8

25

9

CK-101 CK-1028

9

VAULT SECTION8

M. KAVANAUGHM. KAVANAUGH

L. LINDEEN6

P-002DESCRIPTION OF ISSUE / REVISIONREVISION REVISED BY

M. KAVANAUGHSPRUCE POINT

AIR INJECTION VAULT DRAWING:

SHEET:

DRAWN BY:

OF

PROJECT: 171005.01

DESIGNER:APPROVED BY:

DW

G:

S:\2

00 P

roje

cts\

1710

05.0

1-M

ontro

se A

ir In

ject

ion

Stat

ion\

900

CAD

\02-

SHEE

TS\P

-002

.dw

g

USE

R: m

kava

naug

hD

ATE:

Oct

10,

201

9 8

:14p

m

XR

EFS:

G-M

AI-B

D

G-M

AI-S

UBM

IT

P-M

AI-V

AULT

PLA

N A

ND

SEC

TIO

NS_

1

IMAG

ES:

VERIFY SCALEBAR IS ONE INCH ONORIGINAL DRAWING

IF NOT ONE INCH ON THISSHEET, ADJUST SCALES

ACCORDINGLYFINAL FOR BID

PROVIDENCE INFRASTRUCTURE CONSULTANTS4901 EAST DRY CREEK ROAD, SUITE 210CENTENNIAL, CO 80122TEL: (303)997-5035www.providenceic.com

10/11/2019

CITY OF MONTROSE

M

O

N

TROS

E

C

OLO

RA

D

O

10/11/19FINAL FOR BID

SCALE: VAULT SECTION

3/4" = 1'-0"A

P-001 SCALE: PIPING SECTION

1-1/2" = 1'-0"B

P-001

NOTES:1. VAULT SUPPLIER SHALL SUBMIT AIR INJECTION BLOWER AND PIPING DESIGN FOR APPROVAL OF ENGINEER.

2. PROVIDE 12" THICK LAYER OF 1-1/2" ANGULAR, CRUSHED, WASHED ROCK STABILIZATION MATERIALBENEATH FOUNDATION SLAB OF VAULT. VIBRATE TO COMPACT TO 70% RELATIVE DENSITY.

3. PLACE CONCRETE SLAB ON UNDISTURBED EARTH. IF UNSUITABLE MATERIAL IS FOUND AT BOTTOM OFEXCAVATION, IT SHALL BE REMOVED AND REPLACED WITH 1-1/2" CRUSHED ROCK STABILIZATION MATERIAL.

4. INSULATE ALL AIR PIPING TO PROTECT WORKERS FROM HIGH TEMPERATURE.

5. EXHAUST DUCT SHOWN OUT OF ROTATION IN THIS SECTION. SEE SHEET P-001 FOR LOCATION.

6. SOME PIPING IS NOT SHOWN IN DETAIL. PROVIDE ALL PIPE AND FITTINGS REQUIRED TO COMPLETEINSTALLATION INCLUDING REDUCERS, BUSHINGS AND ANCILLARY MATERIALS REQUIRED FOR CONNECTIONOF SUPPLIER ARRANGED EQUIPMENT LAYOUT.

EQUIPMENT AND MATERIALS LISTID TAG NO. DESCRIPTION

1 P-101 10 HP CLAW PUMP, 3 PH, 230 V, 60 HZ, AIRTECH, BUSCH MINK, LEYBOLD OR APPROVED EQUAL

2 AC-101 AFTER COOLER W/ INTEGRAL FAN, 50 CFM CAPACITY MINIMUM, AKG OR EQUAL

3 P-102 1/2-HP SUMP PUMP W/ FLOAT SWITCH, 1 PH, 120 V, 60 HZ, ABS, ZOELLER OR EQUAL

4 1-1/4"x1" 316 STAINLESS STEEL (SST) UNION

5 1-1/4" 316 SST 90 DEGREE BEND

6 1-1/4" x 1" 316 SST REDUCER

7 1" 316 SST 45 DEGREE ELBOW

8 1" 316 SST TEE

9 1" 316 SST 90 DEGREE BEND

10 1" 316 SST UNION

11 1" SCH 40 316 SST PIPE

12 1" 316 SST BALL VALVE, FULL PORT, LEVER ACTUATED, TWO-PIECE, APOLLO 76F OR EQUAL

13 CK-101 1" 316 SST CHECK VALVE (IN-LINE SPRING TYPE), MAXIMUM CRACKING PRESSURE 0.50 PSI

14 CK-102 1" 316 SST CHECK VALVE (BALL TYPE), MAXIMUM CRACKING PRESSURE 0.50 PSI

15 CV-101, CV-102 1" 316 SST BALL VALVE, ELECTRICALLY ACTUATED, OPEN/CLOSE TYPE, DYNAQUIP OR EQUAL

16 SV-101 1/2" SOLENOID VALVE, NORMALLY CLOSED, 120 VAC, ASCO RED HAT OR EQUAL

17 SV-102 1/2" SOLENOID VALVE, NORMALLY CLOSED, 120 VAC, ASCO RED HAT OR EQUAL

18 4" AFTER COOLER EXHAUST DUCT

19 EF-101 EXHAUST FAN, IN-LINE DUCT TYPE, FANTECH, DAYTON, OR EQUAL

20 EXHAUST FAN DAMPER

21 LS-101 FLOAT SWITCH, SUMP PUMP ON/OFF CONTROL

22 LS-102 FLOOD SWITCH, GEMS LS-270 OR EQUAL

23 ANODE, TYPICAL OF 2

24 FE/FIT-101 1" THERMAL MASS AIR FLOW METER, SAGE PRIME SIP IN-LINE OR EQUAL

25 PI-101 PRESSURE GAUGE, 0-60 PSI, WIKA, ASHCROFT OR EQUAL

26 CK-103 3/4" CHECK VALVE, BALL TYPE

27 ALUMINUM LADDER

28 DS-101 LOCAL POWER DISCONNECT

29 TS-101 ANODE TEST STATION

30 1/2" 316 SST 45 DEGREE BEND

31 1/2" 316 SST 90 DEGREE BEND

32 1/2" 316 SST TEE

33 1/2" 316 SST BALL VALVE, FULL PORT, LEVER ACTUATED, TWO-PIECE, APOLLO 76F OR EQUAL

34 NV-101 1" 316 SST NEEDLE VALVE, SMITH COOPER S7166NV OR EQUAL

35 EUH-101 ELECTRIC UNIT HEATER, PER SUPPLIER DESIGN

AutoCAD SHX Text

S

AutoCAD SHX Text

S

TAG DESIGNATIONYL EQUIPMENT RUNNING STATUSYS EQUIPMENT IN AUTO OR REMOTE STATUSYY EQUIPMENT RUN COMMANDUA EQUIPMENT FAULT STATUSMC HAND CONTROL

HS HAND SWITCHSI SPEED INDICATIONSC SPEED COMMANDPSL PRESSURE SWITCH LOWPSH PRESSURE SWITCH HIGHFE FLOW ELEMENTFIT FLOW INDICATOR/TRANSMITTERZSO VALVE POSITION FULL OPENZSC VALVE POSITION FULL CLOSEZSI VALVE POSITION INDICATORSP SET POINTPID PROPORTIONAL-INTEGRAL-DERIVATIVEOCA OPEN-CLOSE-AUTOLCP LOCAL CONTROL PANEL

1. THIS IS A STANDARD LEGEND, THEREFORE NOT ALL OF THIS INFORMATION MAYBE USED ON THIS PROJECT.

2. P&ID INSTRUMENTATION DETAILS DO NOT REPRESENT INSTRUMENTS ANDCONTROLS INTEGRAL TO VENDOR SUPPLIED CONTROL PANELS OR EQUIPMENT.

3. P&ID DOES NOT REPRESENT EQUIPMENT HARDWIRED INTERLOCK AND ENABLECIRCUITRY, REFER TO VENDOR SHOP DRAWINGS FOR COMPLETEDESCRIPTION.

M

P&ID EQUIPMENT SYMBOLS

CLOSED OPEN

ELECTRICAL SIGNAL

DATA LINK OR SOFTWARE SIGNAL

M

P&ID INSTRUMENT SYMBOLS

GENERAL NOTES:

ACTUATOR SYMBOLS

PANEL NOMENCLATURE

INSTRUMENTATION LEGENDVALVE SYMBOLS

INSTRUMENTATION IDENTIFICATION LETTERS(INSTRUMENT SOCIETY OF AMERICA)

COMMON INSTRUMENT DESIGNATIONS

FIRST - LETTER SUCCEEDING LETTERS

MEASURED ORINITIAL VARIABLE

READOUT ORPASSIVE FUNCTION OUTPUT FUNCTION MODIFIER

A ANALYTICAL ALARM

B BURNER, COMBUSTION USER'S CHOICE USER'S CHOICE

C CONTROL CLOSED

D USER'S CHOICE DIFFERENTIAL

E VOLTAGESENSOR (PRIMARYELEMENT)

F FLOW RATE RATIO (FRACTION)

G USER'S CHOICE GLASS, VIEWING DEVICE

H HAND HIGH

I CURRENT (ELECTRICAL) INDICATE

J POWER

K TIME, TIME SCHEDULE TIME RATE OF CHANGE

L LEVEL LIGHT LOW

M MOTOR MIDDLE, INTERMEDIATE

N TORQUE USER'S CHOICE USER'S CHOICE

O USER'S CHOICE ORIFICE, RESTRICTION OPEN

P PRESSURE, VACUUM POINT (TEST) CONNECTION

Q QUANTITY INTEGRATE, TOTALIZE

R RADIATION RECORD

S SPEED, FREQUENCY SAFETY

T TEMPERATURE

U FAILURE MULTIFUNCTION MULTIFUNCTION

V VIBRATION, MECHANICALANALYSIS

W WEIGHT, FORCE WELL

X UNCLASSIFIED X AXIS UNCLASSIFIED UNCLASSIFIED UNCLASSIFIED

Y EVENT, STATE ORPRESENCE Y AXIS RELAY, COMPUTE, CONVERT COMMAND

Z POSITION, DIMENSION Z AXIS DRIVER, ACTUATOR

CP-XXX: CONTROL PANEL (AREA CONTROL)

LCP-XXXA: LOCAL CONTROL PANEL (SPECIFICATION PROCESS CONTROL)LETTERS A, B, C DENOTE VENDOR SUPPLIED EQUIPMENT

LP-X: LIGHTING PANEL

POSITION NOTE FOR ONLOSS OF PRIMARYPOWER:

FO = FAILFC = FAIL CLOSEFLP = FAIL IN LAST

ELECTRIC MOTOR

MANUAL OR CHAINWHEEL

SOLENOID

ULTRASONIC LEVELINDICATOR

HYDROSTATIC LEVELSENSOR

ULTRASONIC FLOWSENSOR

ROTAMETER

ROTARY LOBE PUMP

METERING PUMP

EQUIPMENT WASHSERVICEFLUSHING CONTROLSERVICE

CHEMICAL CALIBRATIONCOLUMN

FLOAT SWITCH (FS)

AUTOMATIC SAMPLER

WEIR

YARD HYDRANT

QUICK CONNECT

FLOATING AERATOR/MIXER

INDICATES SHEET LINE ISCONTINUED TOMATCH LETTER TO FINDLINE ON OTHER SHEETPARSHALL FLUME

ELECTROMAGNETIC FLOWMETERPROPELLER FLOW METER

ANNULAR SEAL

DIAPHRAGM SEAL

ORIFICE PLATE

SILENCER

ORP SENSOR

PRESSURE ELEMENT

SUSPENDED SOLIDS METER

POSITIVE DISPLACEMENTDOUBLE DISC DIAPHRAGMPUMP

STATIC INLINE MIXER

FLOATING DECANTER

SAMPLE TAP

FEED TANK AND PUMP

BLIND FLANGE

DRAIN

VERTICAL TURBINE PUMP

PROGRESSING CAVITYPUMP

CENTRIFUGAL PUMPS

SUBMERSIBLE WELL PUMP

METERING PUMP

PERISTALTIC PUMP

GEAR PUMP OR BLOWER -POSITIVE DISPLACEMENT

SINGLE - STAGE BLOWER

MULTI - STAGE BLOWER

INLINE GRINDER

HANDLE OR THROTTLE

MOTOR DRIVER

PRESSURE GAUGE

MANUAL DRAIN

STRAINER

MIXER

HYDROCYCLONE

DRY PIT WET PIT

SPRING PRESSURE RELIEFW/ PRESSURE RELIEF

AIR RELEASE VALVE

SOLENOID ORMOTOR OPERATED VALVE

SAMPLE VALVE/PORT

STOP & WASTE VALVE

TELESCOPING VALVE

INCREASER/REDUCER

GATE VALVE

KNIFE GATE VALVE

PLUG VALVE

GLOBE VALVE

BALL VALVE

BUTTERFLY VALVE

NEEDLE VALVE

SWING CHECK VALVE

PILOT OPERATED PRESSUREREDUCING VALVE W/ DOWNSTREAMPRESSURE SETTINGPILOT OPERATED PRESSUREREDUCING VALVE W/ UPSTREAMPRESSURE SETTING

DIAPHRAGM VALVE

SLIDE GATE (SG)

KNIFE GATE (KG)

SLUICE GATE (SLU)

STOP GATE (STG)

WEIR PLATE (WP)

MUD & FOOT VALVE

HAND OPERATED VALVE

INSTRUMENTS& DEVICES

GRAPHICS ONA COMPUTER

SCREEN

COMPUTERFUNCTIONS

PLC/DCSFUNCTIONS

IN THE FIELDLOCALLYMOUNTED

ON A MAINPANEL ORSCREEN

ON ASUBPANEL

OR REMOTELOCATION

INACCESSIBLE,HIDDEN OR

BACK/INSIDEPANEL

WHERE

WHAT

ZIR305

ZIR305

ZIR305

ZIR305

ZIR305

ZIR305

ZIR305

ZIR305

ZIR305

ZIR305

ZIR305

ZIR305

T THERMOSTAT

HOA HAND-OFF-AUTO

TRUE UNION FITTING

ZIR305

ZIR305

ZIR305

ZIR305

FLANGED CONNECTION

BALL CHECK VALVE

DESCRIPTION OF ISSUE / REVISIONREVISION REVISED BY

M. KAVANAUGHSPRUCE POINT

AIR INJECTION VAULT DRAWING:

SHEET:

DRAWN BY:

OF

PROJECT: 171005.01

DESIGNER:APPROVED BY:

DW

G:

S:\2

00 P

roje

cts\

1710

05.0

1-M

ontro

se A

ir In

ject

ion

Stat

ion\

900

CAD

\02-

SHEE

TS\I-

001.

DW

G

USE

R: m

kava

naug

hD

ATE:

Oct

10,

201

9 8

:14p

m

XR

EFS:

G-M

AI-B

D

G-M

AI-S

UBM

IT

IMAG

ES:

VERIFY SCALEBAR IS ONE INCH ONORIGINAL DRAWING

IF NOT ONE INCH ON THISSHEET, ADJUST SCALES

ACCORDINGLYFINAL FOR BID

PROVIDENCE INFRASTRUCTURE CONSULTANTS4901 EAST DRY CREEK ROAD, SUITE 210CENTENNIAL, CO 80122TEL: (303)997-5035www.providenceic.com

10/11/2019

CITY OF MONTROSE

M

O

N

TROS

E

C

OLO

RA

D

O

P&ID LEGEND AND SYMBOLS8

M. KAVANAUGHM. KAVANAUGH

L. LINDEEN7

I-001

10/11/19FINAL FOR BID

AutoCAD SHX Text

XXXX

AutoCAD SHX Text

SSM

AutoCAD SHX Text

EWS

AutoCAD SHX Text

FCS

AutoCAD SHX Text

K

AutoCAD SHX Text

K

AutoCAD SHX Text

S

AutoCAD SHX Text

KG

AutoCAD SHX Text

XX

AutoCAD SHX Text

USER'S CHOICE

AutoCAD SHX Text

CONTROL

AutoCAD SHX Text

CONTROL STATION

AutoCAD SHX Text

USER'S CHOICE

AutoCAD SHX Text

SWITCH

AutoCAD SHX Text

TRANSMIT

AutoCAD SHX Text

MULTIFUNCTION

AutoCAD SHX Text

VALVE, DAMPER, LOUVER

AutoCAD SHX Text

Y

AutoCAD SHX Text

E

AutoCAD SHX Text

S

AutoCAD SHX Text

ARV

1-1/4" x 1" CK-101

1"

10 HP CLAW PUMP (BLOWER)FLOW RATE: 11 - 50 SCFM

PRESSURE: 20 - 36 PSI

HOAHS101

VFD-101

YS101

REMOTE/LOCALSTATUS

CLAW PUMP VFD

M

VFD

P-101

1" SST AIR

M

AFTERCOOLERDESIGN FINISH TEMPERATURE:

WITHIN 20 DEGREES F OF AMBIENTAIR TEMP

AC-101

1"1"

LOCAL CONTROL

SCADA/PLC/HMI

FIELD

HOAHS201

FANSTATUS

YI201

WASTE SUMP

SV-102

1/2"

1"

1"

SUBMERSIBLE SUMP PUMPFLOW RATE: 5 GPMPRESSURE: 5 PSI

P-102

M

1. ALL STAINLESS STEEL (SST) PIPING AND VALVES SHALL BE TYPE 316. STAINLESS STEEL PIPING SHALL BE SCHEDULE 40 THICKNESS.

2. VAULT SUPPLIER SHALL COORDINATE DESIGN OF PIPING AND COMPONENTS TO MINIMIZE PRESSURE LOSSES SUCH THAT MAXIMUM DESIGN AIRINJECTION FLOW IS ACHIEVABLE.

3. SHOULD ANY CONFLICT EXIST BETWEEN PROCESS DRAWINGS AND THIS SCHEMATIC THE SUPPLIER SHALL PROVIDE ALL COMPONENTS SHOWNON EACH IN THE PRICING AND CLARIFY FINAL CONFIGURATION VIA SHOP DRAWING.

GENERAL NOTES:

SPRUCE POINT LIFTSTATION (EXISTING)

PI-101

8" SDR 21 PVC FM(EXISTING)

DESIGN PRESSURE: 22 PSI

1.5" MAIN AIR INJECTION (SCH 80 PVC)

LS101

1/2" SST DRAIN

8" PVC SAN SEWER(EXISTING)

1" DR21 IPS PVC

AIR INJECTION VAULTINTERIOR

1" SST AIR

SV-101

1/2"

CK-104

TO GRAVITY MANHOLEOUTLET

1" SCH 80 PVC

1. PUMP P-101 SHALL BE CALLED TO RUN BY A TIMER CIRCUIT WITHIN THE PLC. TIMER SHALL BEOPERATOR ADJUSTABLE.

2. MOTOR OPERATED BALL VALVES CV-101 AND CV-102 SHALL BE NORMALLY CLOSED AND SHALL BEENERGIZED TO OPEN UPON PUMP RUN COMMAND AND REMAIN OPEN WHILE PUMP IS IN RUNNINGSTATUS. THE VALVES SHALL FAIL CLOSED AND SHALL EACH BE ABLE TO BE RUN IN HAND, OFF ORAUTOMATIC MODE.

3. EXISTING SPRUCE POINT LIFT STATION PUMPS RUN STATUS SHALL CAUSE AIR INJECTION STATIONTO TURN OFF DURING RUN TIME OF LIFT STATION PUMPS.

4. AFTERCOOLER AC-101 FAN SHALL START UPON AIR INJECTION PUMP RUN COMMAND.

5. SOLENOID VALVES SV-101 AND SV-102 SHALL BE NORMALLY CLOSED. SV-102 AND SV-103 SHALL BEOPENED AT TIMED INTERVAL AND FOR OPERATOR SELECTED DURATION. EACH SHALL OPENSIMULTANEOUSLY TO DRAIN CONDENSATE TO SUMP. OPENING SHALL OCCUR ON OPERATORSELECTED TIME SCHEDULE.

6. FLOAT SWITCH LS-101 SHALL CONTROL SUMP PUMP P-102.

7. FLOOD SWITCH LSH-102 SHALL BE USED TO ALARM TO SCADA AND ALERT ON-CALL STAFF OFIMMINENT STATION FLOOD VIA COMMUNICATION SYSTEM.

8. THE FOLLOWING ALARMS SHALL BE COMMUNICATED VIA SCADA SYSTEM TO ON-CALL PERSONNEL.A. ZA-101 UNAUTHORIZED ENTRYB. YA-101 GENERAL PUMP/BLOWER FAULTC. LAH-102 FLOOD ALARMD. FAL-101 LOW AIR FLOW ALARM (WHILE PUMP IS IN RUN STATUS)

CONTROL NARRATIVE:

LSH102

LEVELALARM

LAH102

0-60 PSI

NCNC

NC

1"

YL101

PUMP RUNSTATUS

SI101

SPEEDINDICATION

SC101

SPEEDCOMMAND

HATCH SENSORINTRUSION ALARM

ZS101

YA101

GENERAL FAULTALARM

ZA101

FE101

FIT101

TI101

TEMPERATUREINDICATION

IN-LINE AIRFLOW METERMAX. FLOW:110 SCFM

PI101

PRESSUREINDICATION

SPRINGCHECK

1"1.5" WETWELL AERATION LINE (SCH 80 PVC)

CV-101

1" NCM

1"CK-102

BALLCHECK

1"

1/2"

1/2"

AIR INJECTION VAULTEXTERIOR

WETWELL AERATIONDIFFUSER

FLOW RATE: 5 CFMPRESSURE: 20 PSI

DF-101

FI101 FLOW RATE

FQI101 FLOW TOTALIZATION

NV-101

NEEDLEVALVE

PVC BALLCHECK

1" x 1-1/2"

1" x 1-1/2"

CV-1021"NCM

EUH101

TEMPERATURESETTINGSWITCH

TC201

ELECTRIC UNITHEATER, FIELDMOUNT

1" SST AIR

FAL101 LOW FLOW ALARM

DESCRIPTION OF ISSUE / REVISIONREVISION REVISED BY

M. KAVANAUGHSPRUCE POINT

AIR INJECTION VAULT DRAWING:

SHEET:

DRAWN BY:

OF

PROJECT: 171005.01

DESIGNER:APPROVED BY:

DW

G:

S:\2

00 P

roje

cts\

1710

05.0

1-M

ontro

se A

ir In

ject

ion

Stat

ion\

900

CAD

\02-

SHEE

TS\I-

101.

dwg

U

SER

: mka

vana

ugh

DAT

E: O

ct 1

0, 2

019

8:1

4pm

X

REF

S: G

-MAI

-BD

G

-MAI

-SU

BMIT

IM

AGES

:

VERIFY SCALEBAR IS ONE INCH ONORIGINAL DRAWING

IF NOT ONE INCH ON THISSHEET, ADJUST SCALES

ACCORDINGLYFINAL FOR BID

PROVIDENCE INFRASTRUCTURE CONSULTANTS4901 EAST DRY CREEK ROAD, SUITE 210CENTENNIAL, CO 80122TEL: (303)997-5035www.providenceic.com

10/11/2019

CITY OF MONTROSE

M

O

N

TROS

E

C

OLO

RA

D

O

PROCESS & INSTRUMENTATIONDIAGRAM 8

M. KAVANAUGHM. KAVANAUGH

L. LINDEEN8

I-101

10/11/19FINAL FOR BID

AutoCAD SHX Text

S

AutoCAD SHX Text

S

Related Documents