-

7/28/2019 Outdoors Latch Air

1/5

W O R K S H O P

Outdoor Slat Chair B Y B R U C E K I E F F E RCross a park bench with an Adirondack to create a unique seat

T he design for this patio chairhas been coming together inmy head for a long time. Ithink of it as a cross between a parkbench and an Adirondack chair.Im not fond of Adirondacks; I ndthem too hard to get in and outof. My adaptation feels more like aregular chair. Its rock-solid, easy tobuild and unusual-looking enoughto be a conversation starter.

I spent a lot of time adjusting theprototype to make it comfortableand to achieve the look I wanted.(I considered adding arms but de-cided they would detract from theunique all-slat design.) The holes inthe tops of the sides are handholdsso the chair can be easily grabbedand moved. The chair is made fromcedar, which is rot-resistant; I left

mine unnished so it would weath-er to a natural gray color. You couldapply exterior-rated stain or nish,but keep in mind that there are alot of hard-to-reach surfaces thatwill be difcult to nish.

Construction notesYou can expect to spend about $100for materials and eight hours onconstruction. Youll need a tablesaw, a jigsaw, ve 18-in. bar clamps,three 36-in.-opening pipe clamps,one 24-in. bar clamp and another24-in. clamp that can be convertedto a spreader, a pneumatic brad-nailgun, a router, a top-bearing patternbit and a 1/8-in.-radius roundoverbit (see SOURCES ONLINE). I alsoemployed a surface planer becausethe cedar that I bought at my local

home center was 7/8 in. thick andone face was rough sawn. I used theplaner to remove the rough face andmake the wood 3/4 in. thick. It ispossible to build the chair withoutplaning the wood just orient therough faces to the back, bottom. etc.

The sides of the chair are cutfrom large blanks of edge-gluedcedar boards. You must use wa-terproof glue to create the blanks;otherwise the chair will fall apartwhen exposed to the elements.The slats are fastened with water-proof glue and galvanized brads setwith a pneumatic nail gun. Dontbe tempted to forgo gluing the slatsto the sides gluing is essentialto the strength of the chair. Whenyoure gluing the parts together,use a damp (not wet) rag to remove

PHOTOGRAPHY BY SCOTT JACOBSON AND MICHAEL ANDERSON

A winning combination of form and func-tion this outdoor chair is comfort-able and lightweight, and it features amodern style that makes a statement.

-

7/28/2019 Outdoors Latch Air

2/5

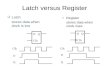

1/2" spacing(typical)

Round over topedges of all slats

Nail and glue all slats to sidesC1, C2 2 nails per side,C3, C4 1 nail per side

Glue and nailor screwstiffeners tosides

Fastenslat C1 first

45

10

0 8"

8"

16"

16"

24"

24"

32"

32"

45

3/4" rad.(typical)

SIDE GLUE-UP

PATTERN / SECTION VIEW 15

C3

C3

C3

C3

C1(Starthere)

C2

C2

C2

B1

B1

B2

B2

B3

B3

C4

C2

C2C4

C2

A2

A2

A2

A2

A1

A1

A1

Edge glue boards

5-1/8" (typical)

Eachsq.= 2"

ILLUSTRATION BY GABRIEL GRAPHICS

OUTDOOR SLAT CHAIR

-

7/28/2019 Outdoors Latch Air

3/5

CUTTING LISTCedarKey No. Description Dimensions A1 6 Sides 3/4 x 5-1/8 x 33 in. A2 8 Sides 3/4 x 5-1/8 x 14-1/2 in. B1 2 Stiffeners 3/4 x 2-1/2 x 21-1/2 in. B2 2 Stiffeners 3/4 x 2-1/2 x 17-1/2 in. B3 2 Stiffeners 3/4 x 2-1/2 x 14-1/2 in. C1 1 Slat 3/4 x 2 x 22 in. C2 30 Slats 3/4 x 1-1/2 x 22 in. C3 10 Slats 3/4 x 1 x 22 in. C4 9 Slats 3/4 x 3/4 x 22 in.

SHOPPING LIST1x6 x 8-ft. cedar boards(10; includes extramaterial to allow for 25 percent waste)1/4-in. x 36-in. x 36-in.hardwood plywood (1)18-gauge x 1-1/4-in. and18-gauge x 1-1/2-in.galvanized bradsWaterproof glueSpray adhesive

excess glue. (Dried glue is hard tosand off.)

Working with cedar can befrustrating. I bought construction-grade lumber to save money. It hada lot of knots, some sapwood (very

light color) and some separationsalong the growth rings. Workingaround these defects takes timeand planning. Carefully decidewhich board to use for each part.Any included knots must be tightand small. Dont use boards withknots or defects for the 3/4-in.-wide slats (C4), and make sure thatall of the wood you use is structur-ally sound. I wound up with about25 percent waste, which is not un-usual with low-grade cedar.

Creating the templateThe shapes of the sides are routedusing a pattern bit guided againsta 1/4-in.-thick plywood template.You have two options for makingthe template. If you have accessto the Internet and a copy centerwith a large-format printer, youcan download the full-size PDF (seeWeb Extras), send or take it to thecopy center and have it printed.The printing instructions appearon the PDF le. It cost me $7 toprint the pattern full-size wellworth the minor expense.

To mount the printout on a1/4-in.-thick x 36-in.-square pieceof hardwood plywood, rst apply alight coat of spray adhesive to thepaper pattern and to the face of theplywood. Let both pieces dry. Cut a36-in.-square piece of cardboard orposter board. Lay the cardboard onthe plywood and the printout onthe cardboard. (The dried adhesivewont stick to the cardboard.) Slow-ly pull the cardboard out and pressthe pattern onto the plywood. Thetwo surfaces with the dried adhe-sive will stick to each other.

The other option is the low-tech,old-fashioned method of transfer-ring the small grid pattern to alarger grid by hand. Draw a 2-in.grid on a 36-in.-square x 1/4-in.-

Poker chip

Lay out the 2-in. grid on a 36-in.-square x 1/4-in.-thick piece of plywood. Mark theintersection points shown on the original pattern; then connect the dots to create theshape. A poker chip is the perfect diameter for drawing the radius on the bottom cor-ners of the legs.

Use pipe clamps when you glue the short upper pieces to the side panels. Place twoclamps underneath and one on top. To prevent the metal from staining the workpiece,cover the part of the pipe that touches the glue joint with masking tape.

Maskingtape

1

2

To download a full size pattern of the sides, go towww.HandymanClub.com and click on Web Extras.

-

7/28/2019 Outdoors Latch Air

4/5

hick piece of plywood (photo 1, p. 9). Referring to thelustration (p. 8), mark the points where the shape

ntersects with the grid; then connect the dots toreate the shape.

Once youve transferred the pattern to the ply-wood, drill a starter hole for the handhold. Using a

gsaw, carefully cut out that opening and the shape

Rout the shape of each side using a top-bearing pattern bitsee SOURCES ONLINE) guided against the template. Use a lot oflamps to secure the template in place. Youll need to move thelamps as you work to complete the routing.

Template

Side panel

Anti-sliprouter pad

Round over the top edges of the slats using a 1/8-in. roundoverrouter bit (see SOURCES ONLINE). Ganging the slats to rout theends greatly speeds the work.3

4

C2slats

of the sides; then sand the sawn edges smooth. Takeyour time your chair sides will only be as good asyour template.

Making the sidesOnce youve completed the template, cut pieces A1and A2 to size (see cutting list, p. 9). Youll need to

glue together three A1 pieces for each side: First gluewo pieces and let that joint dry; then add the third

piece. Next, working with the faces up and using pipeclamps (photo 2), add the A2 pieces one at a time tohe side panels. (Cedar is too soft and pliable to use bar

clamps for this step I tried, and the assemblies justkept popping apart under pressure.) Keep in mind that

as you work with the faces up, you need to add the

short pieces to opposite ends of the blanks so that youcreate both a right and a left side blank.

Align the template leg bottoms with the bottomedges of the side blanks and trace the shapes onto eachblank. Use a jigsaw to cut out the shapes. Cut close to thelines, but leave 1/16 in. to 1/8 in. extra to be trimmedaway when you rout the shape. Be very careful when

handling the sides; at this stage they are very imsy.

Align the two sides face-to-face, and use a combination square todraw lines across the outside edges. These lines are visual aidsfor keeping the slats aligned as they are added.

Approximately 5 in.

5 Glue and nail the rst slat in place using a pneumatic brad nailerand 18-gauge x 1-1/2-in.-long galvanized brads. Place two brads ateach end. Use a damp rag to remove any excess glue before it dries.

C1 slat

Temporary

supports6

-

7/28/2019 Outdoors Latch Air

5/5

1/2-in. spacer

Alignmentline

7

Next, make the stiffeners (B1, B2 and B3). Use glueand 1-1/4-in. screws or brads to fasten the stiffeners tothe inner faces of the sides. Once the stiffeners are inplace, the sides will be much sturdier. The stiffenersalso raise the sides to make routing easier. Align andclamp the template to each rough-cut side and routthe shapes (photo 3, p. 10).

Assembling the chairMake all of the slats (C1 through C4). Cut a few extrasof each size in case you nd a few bad ones duringassembly. Round over the top edges (photo 4); thennish sand the slats.

Draw slat-alignment lines across the outside edges of the chair sides (photo 5, p. 11). Space the lines roughlyevery 5 in. These guides will help you to space the slatsevenly and keep the slats perpendicular to the sides.

Set the sides upright and temporarily clamp a C2slat at the outside bottom of the front and rear legs.This denes the spread between the sides and holdsthe sides so that its easier to attach the rst batch of slats. Position the rst slat (C1) tight in the corner be-tween the seat and the back; then fasten it with glueand nails (photo 6).

Attach the next few seat and back slats (photo 7).

Finish adding the seat top slats, including four C3 slats.Use one brad at each end when attaching the C3 and C4slats. Then lay the chair on its back and add the rest of the seat back slats (photo 8, opposite). Continue addingslats, being careful to attach the correct number of C3and C4 slats in the proper sequence. Flip the chair overand add the back slats (photo 9). Flip the chair over againand add the remaining front slats.

As you add slats near the leg bottoms, you may nd

When adding the slats, you may need to spread the sides aparta bit so the slat ends are ush with the sides. Use a spreaderclamp to do this.

8SpreaderclampTemporarysupport

1/2-in.spacer

As you add the slats, you may need to pull the sides closertogether so the slat ends are ush with the sides. Use a 24-in.bar clamp to do this.

9

that you need one more or one less C2 slat to com-plete your chair. (This would result from a cumulativespacing error, but its nothing to worry about.) Stopadding slats when the next one would cover any partof the radius corners of the leg bottoms.

All thats left is to nish sand the chair sides andany remaining unsanded surfaces and smooth allsharp edges. Theres no need to ll the nail holes.Your chair is ready to take outside and enjoy.

Handyman Club life member Bruce Kieffer is a customfurniture builder, freelance woodworking author and tech-nical illustrator. You can see a collection of his work at www.kc.biz.

Woodworkers Hardware

(CMT Pattern Series straight router bit, No. CMT811.690.11B;

CMT 1/8-in.-radius roundover bit, No. CMT838.190.11)800-383-0130, www.wwhardware.com

S O U R C E S O N L I N E

For online information, go to www.HandymanClub.com and click on WEB EXTRAS.