Next Generation Beverage Mold Solutions August 2016

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Productivity Improvements

Maximizing cavitation

Stack molds

Injection Machine Dry Cycle Reduction

Energy consumption

Enhanced cooling, ejection, and release:

materials with high rate of heat transfer

conformal cooling with advanced steel bonding

Consistent ejection

Productivity Trends

Gen 3.0 Prototype Closure Mold

• Standardized prototype designs

• 1 cavity & 4 cavity configurations

• Focused on part optimization

• Pre-qualified designs at optimal part weight & cycle

• Customized for specific applications

Closure Development

YearGen 12010

Gen 22012

Gen 32014

Closure 1881 1881 1881

Part Weight 2.45g 2.45g 2.45g

Cavitation 72 96 96

Cycle 4.7 sec 4.1 sec 3.5 sec

Parts per Year(millions) 441.2 674.3 789.9

Productivity Improvement - Closure Molds (UCL)

More durable (less maintenance)

DLC coatings

Static inner core

Stack component alignment subordinated to each individual stack

No service connections on the bottom of the mold

Clamping force directed through the mold plates not the core stack components

10-15% reduction in tonnage

Less complex mold (fewer parts and controls)

No Ejector box

No racks, pinions, needle bearings or cam followers

No stripper plate latches

No straight side locks

No limit/proximity switches

No slide actuation cylinders

No water manifolds

Faster cycle time

Gen 3.0 Tamper Evident Beverage Closure Mold Design

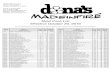

Cavitation Number Of Molds Number Of Stacks Location Annualize Capacity

16 1 16 Asia 98,918,400

32 6 192 Asia/EU 1,176,510,638

48 19 912 Asia/EU/SA 5,588,425,532

64 2 128 Middle East 784,340,426

72 7 504 Asia/SA 1,780,531,200

96 9 672 SA 6,220,800,000

Totals 44 2,424 15,649,526,196

Largest Installed Base of UCL Beverage Closure Molds

0

100

200

300

400

500

600

700

800

900

2010 2012 2014 2016

?Gen 1.0

Gen 2.0

Gen 3.0

Next Gen

Productivity Improvement of Gen 3.0 Closure Molds

Optimized cooling channels follow part geometry in 3D

Proprietary bonding process in stack manufacturing

Design based on heat transfer simulation yields faster cycle

Enhanced Cooling via KoolTrack™

OLD PART

Conventional

design

NEW PART

5 piece

collapsing core

design

Water Cooled Collapsing Core Design – Caps & Jars

• Productivity continues to improve driven by mold and machine technology

• Collaboration creates value and reduces part costs

• Increasing sophistication of mold design and manufacturing

• Ongoing part design improvements and weight reductions continue to drive overall part costs down

• Early mold maker collaboration in part development is key

Conclusions

Related Documents