SAP – Material Management (MM) Module MMIM1010 – IM: Maintain Material Master for PRT1- Spare Parts Submit Date, 18-May-04 Internal Use © Copyright @ 2004 Holcim Services (Asia) Ltd.

MM - Material Master 00

Oct 11, 2015

Material Master 00

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

-

SAP Material Management (MM) Module

MMIM1010 IM: Maintain Material Master for PRT1- Spare Parts

Submit Date, 18-May-04 Internal Use

Copyright @ 2004 Holcim Services (Asia) Ltd.

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 2/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

Document Control Document Name BPP Document: MMIM1010 MM: Maintain Material Master for for PRT1-

Spare Parts Author BPP Re-Documentation Team File Name & Path Created 17-May-04 Last Edited 31-May-04 Printed on 12-Nov-04

Version Revision Date Revision Description Author Sign-off 1.0 First modified documentation NIIT-MM

Team

2.0 01-Sep-04 Reviewed document by UCC& HSEA

HSEA

3.0 09-Nov-04 Reviewed document by HSEA MM functional team

HSEA-MM

Document Approval

Role Name Signature Date HSEAs Training and web TECHNOLOGY Manager

Rawee Chaimongkol

HSEAs Senior IT Training Specialist

Kathaleeya Srivoranart

Distribution List

Role Name Signature Date

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 3/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

Table of Contents

OVERVIEW .......................................................................................................................................... 4 TRIGGER............................................................................................................................................. 4 TIPS AND TRICKS................................................................................................................................. 4

PROCEDURAL STEPS ....................................................................................................................... 5 1. CREATE MATERIAL MASTER PRT1 SPARE PARTS .................................................................. 5 2. CHANGE MATERIAL MASTER PRT1 SPARE PARTS................................................................ 26 3. DISPLAY MATERIAL MASTER PRT1 SPARE PARTS................................................................ 31

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 4/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

Overview

Trigger The Material Master to be created for every material that a company procures or produces, stores, and sells.

Business Process Procedure Overview Material Master contains the information on all the materials. It is the company's central source for retrieving material-specific data. This information is stored in individual material master records.

Input Comment Physical characteristics Physical characteristics include unit of measurement, size,

volume etc. Requirement details Requirement details are, How the material is required?, How

much it is required and maximum ordering and stock quantity planned delivery time by the supplier etc.

Accounting details Material price, its valuation class, Currency used to purchase the material etc.

Storage conditions Maximum storage period, storage climatic conditions, self life expiration time etc.

Output / Results Comment Material Data Complete details of the material created and maintained in a

single database file i.e. Central repository of the material.

Tips and Tricks

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 5/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

Procedural Steps

1. Create Material Master PRT1 Spare Parts

1.1. Access transaction by Via Menu Logistics Material Management Material Master

Material Create (general) Immediately Via Transaction Code MM01

Fig01

Key T-Code, MM01

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 6/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.2. On screen Create Material (Initial Screen), enter information in the fields as specified in the table below:

Fig02

Field Name Description R/O/C/D User Action and Values

Material Material Number R Enter the Material Number as per your companys standard

Industry sector Key that specifies the branch of industry to which the material is assigned.

R Select your Industry sector from dropdown menu

Material type Key that assigns the material to a group of materials such as raw materials, operating supplies or trading goods.

R Select Material type from dropdown menu

Copy from Material

Number of the material whose data you want the system to copy as default values.

O Enter material number if you want to copy existing material

Press ENTER or click on button

Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 7/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.3. On pop-up window Select view(s), select the box (screen) in which this material must be maintained.

Fig03

Field Name Description R/O/C/D User Action and Values

Select View(s) (View selection Box)

Selection of views (screens) for data entry.

R Select the views you want to maintain for this material. If you want select all

screens click on

Press ENTER or click on button Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 8/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

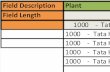

1.4. On pop-up window Organization Levels, enter the organization level in which material must be maintained.

Fig04

Field Name Description R/O/C/D User Action and Values

Plant Plant for which the material is to be created.

R Enter the Plant Name or Number or select it from the drop down menu.

Storage Location Storage Location for which the material is to be created.

R Enter the storage Location Name or Number or select it from the drop down menu.

Press ENTER or click on button

Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 9/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.5. On screen Create Material , maintain information for basic data1 of material as specified in the table below:

Fig05

Field Name Description R/O/C/D User Action and Values

Material Description of the material.

R Enter meaningful description of the material

Base unit of measure

Unit of measurement in which the material is measured.

R Enter the Base unit of measure or select it from the drop down menu.

Material group Materials having similar properties are grouped together for Accounting purpose.

R Enter the Material group or select it from the drop down menu.

Old Material number

Number under which you have managed the material so far or still manage it, for example, in another system or in a card index.

O Enter the Old Material number

Press ENTER or click on button

Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 10/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.6. On screen Create Material : maintain information for basic data2 of material as specified in the table below:

Fig06

Field Name Description R/O/C/D User Action and Values

No Entry required in this screen

Press ENTER or click on button Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 11/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.7. On screen Create Material : maintain information for purchasing data of material as specified in the table below.

Fig07

Field Name Description R/O/C/D User Action and Values

Order Unit The unit of measure in which the material is ordered

O Enter order unit in case of order unit difference from base unit of measure

Purchasing group Key for a buyer or group of buyers responsible for certain purchasing activities. The purchasing group is internally responsible for the procurement of a material or a class of materials. Usually the principal channel for a company's dealings with its vendors.

R Enter purchasing group or select it from the drop down menu.

Purchasing Value Key

Key defining the valid reminder days and tolerance limits applicable to this material for the purchasing department.

R Enter the purchasing value key for the material or select it from the drop down menu.

GR processing time

Goods Receipt processing time (Number of workdays required after receiving

O Enter Goods Receipt (GR) processing time.

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 12/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

Field Name Description R/O/C/D User Action and Values the material for inspection and placement into storage.)

Press ENTER or click on button

Legend: R = Required, O = Optional, C = Conditional, D = Display

1.8. On screen Create Material : maintain information for foreign trade import of material as specified in the table below.

Fig08

Field Name Description R/O/C/D User Action and Values

No Entry required in this screen Press ENTER or click on

button Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 13/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.9. On screen Create Material : maintain the Purchase order text or the details of the material to be specified in purchase order (If required) in this screen.

Fig09

Field Name Description R/O/C/D User Action and Values

Langs Maintained Language in which the material description to be printed on purchase order

R Enter Language

Long Text Detailed description of material to be printed on purchase order

O Enter description of material to be printed on purchase order

Press ENTER or click on button

Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 14/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.10. On screen Create Material : maintain information for MRP1 data of material as specified in the table below.

Fig10

Field Name Description R/O/C/D User Action and Values

MRP type Material Requirement Planning type (Key that controls the MRP procedure (MRP or reorder point) to be used for planning a material. It contains additional control parameters, for example, for using the forecast for the materials planning, for firming procurement proposals etc.)

R Enter MRP type or select it from the drop down menu.

Reorder point Reorder point ((If the stock falls below this quantity, the system flags the material for requirements planning)

O Enter minimum stock Quantity (If the stock falls below this quantity, the system flags the material for requirements planning)

MRP Controller MRP Controller is the person responsible for a group of materials within MRP in a plant or company.

O Enter responsible MRP Controller for Material planning or select it from the drop down menu.

Lot Size Lot size of the material (The system uses within

R Enter lot size procedure.

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 15/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

Field Name Description R/O/C/D User Action and Values materials planning to calculate the quantity to be procured or produced.)

Maximum stock level

Quantity that is not allowed to be exceeded during procurement.

O Enter Maximum stock level

Press ENTER or click on button

Legend: R = Required, O = Optional, C = Conditional, D = Display

1.11. On screen Create Material : maintain information for MRP2 data of material as specified in the table below.

Fig11

Field Name Description R/O/C/D User Action and Values

Plnd delivery time Planned delivery time accepted by the vender to deliver the material.

R Enter Planned delivery time in days.

GR processing time

Goods Receipt processing time (Number of workdays required after receiving the material for inspection and placement into storage.)

R Enter Goods Receipt (GR) processing time.

Press ENTER or click on button

Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 16/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.12. On screen Create Material : maintain information for MRP3 data of material as specified in the table below.

Fig12

Field Name Description R/O/C/D User Action and Values

Availability check Availability check procedure makes sure that there are enough components available for the planned/production orders in production planning and production control.

R Enter Availability check or select it from the drop down menu.

Press ENTER or click on

button Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 17/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.13. On screen Create Material : maintain information for MRP4 of material as specified in the table below.

Fig13

Field Name Description R/O/C/D User Action and Values

No Entry required in this screen. Press ENTER or click on

button Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 18/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.14. On screen Create Material : maintain information for Plant data/ stor.1 of material as specified in the table below.

Fig14

Field Name Description R/O/C/D User Action and Values

Storage bin Storage bin (Identifies the storage bin within a storage location where the material is stored.)

O Enter Storage Bin within a storage location where the material is stored

Unit of issue Unit of Issue (Unit in which the material is issued from the warehouse)

O Enter Unit of issue. In case the unit of issue is differs from base of unit.

Press ENTER or click on

button Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 19/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.15. On screen Create Material : maintain information for Plant data/stor.2 of material as specified in the table below.

Fig15

Field Name Description R/O/C/D User Action and Values No Entry required in this screen.

Press ENTER or click on button Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 20/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.16. On screen Create Material : maintain information for Accounting 1 data of material as specified in the table below.

Fig16

Field Name Description R/O/C/D User Action and Values

Valuation category Criterion for the separate valuation of different stocks of a material managed under a single material number.

C Enter Valuation category or select it from the drop down menu.

Valuation class Through valuation class Material is assigned to a group of G/L accounts.

R Enter valuation class for the material or select it from the drop down menu.

Price control Indicator determining the procedure used for material valuation.

R Enter Price control (V for Mov.avg.price, S for Standard price)

Mov.avg.price Price those changes in consequence of goods movements and the entry of invoices, and which is used to valuate the material.

C Enter Moving average price

Standard price Constant price at which a material is valuated without taking goods movements and invoices into account.

C Enter Standard price.

Price unit Number of unit(s) to which the price refers.

O Enter price unit.

Press ENTER or click on

Currency used toValuate the Materialfor example, ThaiBaht, US Dollar etc.

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 21/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

Field Name Description R/O/C/D User Action and Values

button Legend: R = Required, O = Optional, C = Conditional, D = Display

1.17. On screen Create Material : maintain information for Accounting 2 data of material as specified in the table below.

Fig17

Field Name Description R/O/C/D User Action and Values No Entry required in this screen.

Press ENTER or click on button Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 22/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.18. On screen Create Material : maintain information for Costing 1 data of material as specified in the table below.

Fig-18

Field Name Description R/O/C/D User Action and Values

With quantity structure

With quantity structure (This indicator determines whether the material is costed in costing with or without a quantity structure.)

R With quantity structure

Material origin Material origin (If this indicator is set, the material number will be written to the cost element itemization in the Controlling module.)

R Material origin.

Press ENTER or click on button

Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 23/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.19. On screen Create Material : maintain information for Costing 2 data of material as specified in the table below.

Fig19

Field Name Description R/O/C/D User Action and Values

No Entry required in this screen. Press ENTER or click

on button Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 24/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.20. On the last screen a Warning message appeared You are about to exit. Do you want save your data for this material first and waiting for confirmation.

Fig20

Field Name Description R/O/C/D User Action and Values Click on YES button

Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 25/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

1.21. Save the transaction. The Message appeared Material created at bottom left hand side of the screen.

Fig21

Field Name Description R/O/C/D User Action and Values

Note down the material number for this material. Material Master has been created.

Legend: R = Required, O = Optional, C = Conditional, D = Display

Material Number

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 26/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

2. Change Material Master PRT1 Spare Parts

2.1 Access transaction by Via Menu Logistics Material Management Material Master

Material Change Immediately Via Transaction Code MM02

Fig -22

Key T-Code, MM02

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 27/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

2.2 On Change Material Initial Screen, Enter information in the fields as specified in the table below:

Fig23

Field Name Description R/O/C/D User Action and Values Material Material Number to which

you want change R Enter the Material Number

Change number Number used to uniquely identify a change master record.

O Enter Change number

Press ENTER or click on

button Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 28/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

2.3 On the pop up window Select view(s) Select the view (screen) in which you want to change the data:

Fig24

Field Name Description R/O/C/D User Action and Values

Select View(s) (Selection Box)

View selection O Select the desired views. If you want to select all views click on

Press ENTER or click on button Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 29/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

2.4 On pop-up window Organizational Levels, enter the organizational level to which the material belongs:

Fig25

Field Name Description R/O/C/D User Action and Values

Plant Plant Name or Number to which the material belongs.

O Enter the Plant Name or Number

Press ENTER or click on button

Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 30/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

2.5 The selected screen will be displayed change data whatever you want to change. Here Purchasing screen is shown for example (Change Material ).

Fig-26

Field Name Description R/O/C/D User Action and Values

Press ENTER or click on button

Legend: R = Required, O = Optional, C = Conditional, D = Display

2.6 After changing the data hit ENTER or click on a confirmation box for save will be

displayed click on YES to save the document. Or click on to save the document, the document will be saved and appropriate message will be displayed.

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 31/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

3. Display Material Master PRT1 Spare Parts

3.1. Access transaction by Via Menu Logistics Material Management Material Master

Material Display Display Current Via Transaction Code MM03

Fig27

Key T-Code, MM03

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 32/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

3.2. On screen Display Material (Initial Screen), Enter information in the fields as specified in the table below:

Fig28

Field Name Description R/O/C/D User Action and Values Material Material Number to which

you want display R Enter the Material Number

Press ENTER or click on

button Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 33/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

3.3. On screen Display Material (Initial Screen), Enter information in the fields as specified in the table below:

Fig-29

Field Name Description R/O/C/D User Action and Values Selection Box (Select Views)

View selection R Select the desired views. If you want to select all views click on

Press ENTER or click on button Legend: R = Required, O = Optional, C = Conditional, D = Display

-

SAP-MM Module

MMIM1010 MM: Maintain Material Master for PRT1-Spare Parts Internal Use 34/34

W:\HSEA Project\2004\BPP Re_Documentation\4.0 Approved BPPs\MMIM\MMIM1010 Maintain Material Master for PRT1-Spare Parts.doc

3.4. On the Pop-up window Organizational levels, Enter organizational level the material belongs:

Fig30

Field Name Description R/O/C/D User Action and Values

Plant Plant Name or Number O Enter the Plant Name or Number Stor. Location Storage Location O Enter Storage location Valuation type Valuation type O Enter Valuation type

Press ENTER or click on button Legend: R = Required, O = Optional, C = Conditional, D = Display

3.5. After hitting ENTER or click on button, the selected screens will be displayed.

Related Documents