Instructions for use Manuel d’utilisation Istruzioni per l’uso Instrucciones de funcionamiento Bedienungsanweisung Version 1.1 SET START STOP MADE IN THE UK Melting Point Apparatus SMP10 Scientific

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Instructions for useManuel d’utilisationIstruzioni per l’usoInstrucciones de funcionamientoBedienungsanweisung

Version 1.1

SET

START

STOP

MADE IN THE UK

Melting PointApparatus SMP10

Scientific

English

This equipment is designed to operate under thefollowing conditions:-

❖ For indoor use only❖ Use in a well ventilated area❖ Ambient temperature range

+5°C to +40°C❖ Altitude to 2000m❖ Relative humidity not exceeding 80%❖ Mains supply fluctuation not exceeding 10%❖ Overvoltage category II IEC60364-4-443❖ Pollution degree 2 IEC664

If the equipment is not used in the mannerdescribed in this manual the protection providedby the equipment may be impaired.

Thank you for purchasing this BarloworldScientific product. To get the bestperformance from the equipment, and foryour own safety, please read theseinstructions carefully before use.

SET

START

STOP

MADE IN THE UK

SET

START

STOP

MADE IN THE UK

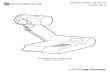

Figure 1

IEC connector

Temperature display

Control panel

Eye viewer

Sample tubeholder

Extendible feet

Instruction facia

Mainson/off

1

Electrical Installation

THIS EQUIPMENT MUST BE EARTHED

Before connection please ensure that theline supply corresponds to that stated on therating label. Power consumption is 70W.

There is an IEC socket at the rear of the righthand side of the instrument for connection to themains supply, (see figure 1). The unit is suppliedwith two mains leads fitted with IEC plugs forconnection to the instrument. One has a U.K. 3pin plug and the other has a 2 pin “Shuko” plugfor connection to the mains supply. Choose thelead appropriate for your electrical installationand discard the other.

Should neither lead be suitable you should obtaina moulded lead locally. If this is not possible, takethe lead with the U.K. plug and replace the plugwith a suitable alternative. See the enclosedinstruction sheet for advice on how to carry outthis procedure.

Should the mains lead require replacement acable of 1mm2 of harmonised code H05W-Fconnected to an IEC 320 plug should be used.N.B. The UK mains lead is protected by a 10Afuse mounted in the plug top.The mains lead should be connected to theinstrument BEFORE connection to the mainssupply.

IF IN DOUBT CONSULT A QUALIFIEDELECTRICIAN

General Description

The Stuart SMP10 has been designed formaximum safety and ease of use. Thetemperature is selected, measured and displayeddigitally ensuring accuracy and avoiding the needfor a glass thermometer. Two samples can betested simultaneously. They are viewed via amagnifying lens with clear observation aided bybuilt in illumination. Extendible feet allow theunit to be operated at the optimum viewingangle. Full access to the block allows easycleaning and maintenance.

Before Using your SMP10 for the first timeOnce the unit is unpacked, select the appropriatechoice of self adhesive instruction label from themulti-language set provided. Peel off the backingand stick the label onto the left side of theSMP10 facia. Apply the label carefully using a flatobject to smooth away air bubbles.

Principle of Operation

The SMP10 melting point apparatus has beendesigned to give both quick and accurate resultsas well as maximum convenience in use.

Melting point samples are placed in a glasscapillary tube which is placed in the aluminiumblock inside the sample chamber. This block isheated and the sample observed through themagnifying lens until the melt occurs. Themelting point temperature may then be easilyread from the large LED display.

In order to avoid the necessity to continuallywatch the sample the SMP10 is equipped with a“plateau” function. This allows a temperature tobe set a few degrees below the expected meltingpoint. The SMP10 will then heat to thistemperature very rapidly (20°C per minute) andhold it until the operator is ready to beginmeasuring. It can safely be left to do thisunattended.

2

Once measuring is started the SMP10 will heatslowly (2°C per minute) from the plateautemperature until the melt occurs. This slow rateof heating allows very accurate melting points tobe obtained.

Before UsePlace the unit on a firm, level surface and extendthe feet at the rear of the instrument so that theunit is at a convenient viewing angle.

Connect to the mains electricity supply andswitch on by means of the mains on/off switch.The actual block temperature will now be shownon the three digit LED display and theillumination in the sample chamber will come on.

Measuring a Melting PointN.B. If the unit has been used recently the blockmay be too hot for your sample. If this is the casepress the stop button and allow the unit to coolbefore proceeding.

1. Prepare sample by placing a small amount inthe end of a glass capillary tube.

2. Decide on a suitable plateau temperature.This should be approximately 10°C belowthe expected melting point of the sample.

3. Check that all 3 function lights areextinguished. If not, press the stop button.

4. Press and hold the set button (the plateaulight will flash). The display will now showthe current plateau temperature. When firstswitched on this will be 50°C but note thatif the unit has recently been used the valuemay have been re-set by the previous user.

5. The desired plateau temperature may nowbe set using the arrow keys to scroll thedisplay up or down as required.

6. Release the set button. The new plateautemperature is now set and all functionlights will go out (The plateau setting can bechecked at any time during operation bypressing and holding the set button). Thisaction will not interfere with the operationof the unit).

7. Insert the tube into the side of the heatingblock via the holes provided. Forconvenience this can be done from eitherside of the block. Look down the magnifierand position the tube so that the samplecan be observed clearly.Caution: The heating block may be HOT.

8. Press the start key. The unit will quickly heatup to the plateau temperature (the heatinglight will be illuminated - see figure 1)

9. Once the plateau temperature has beenreached the plateau light will be illuminatedas well as the heating light - see figure 1. N.B. At low plateau temperatures there maybe some overshoot. Wait until the plateaulight comes on before proceeding in order toensure that the temperature has stabilised.

10. Press the start button again. The block willbegin to heat at the pre-set ramp rate of2°C per minute (The plateau light will goout and the ramping and heating lights willboth be illuminated - see figure 1.)

11. Observe the sample until the melt occursand record the temperature from the digitaldisplay.

12. After the melt has occurred press the stopbutton. All function lights will go out andthe unit will cool to ambient temperature.

13. Pressing the start button again will cause theunit to return to the plateau temperatureinstead of ambient. The heating light willcome on even if the temperature is abovethe plateau and the unit is, in fact, cooling.

3

Cleaning & Servicing

WARNING: Ensure the unit isdisconnected from the mains electricitysupply and allowed to cool beforeattempting any cleaning or servicing.

CleaningPeriodically clean the instrument using a dampcloth and mild detergent solution. Do not useharsh or abrasive cleaning agents.

Broken melting point tubes may be removedfrom the block simply by pushing them throughwith a piece of wire or similar tool.

For access to the block for more thoroughcleaning the sample chamber cover must beremoved.

1. Remove the 3 retaining screws and lift off thecover.

2. Loosen the screw retaining the metal platebut do not remove completely.

3. Push the plate to one side.

4. The glass window in the top of the block maynow be removed.

ServicingAny repairs or replacement of parts MUST onlybe undertaken by suitably qualified personnel.

There are two replaceable fuses on the rear ofthe IEC mains connector. The cause of any fusefailure should be investigated and corrected.

Proceed as follows:1) Ensure the SMP10 is disconnected from the

mains supply.

2) Unscrew the four screws on the base of theunit and remove the base plate. Do notdisconnect or pull on the base earth bondingwire.

3) Two fuses are mounted on the rear of the IECconnector (both ‘Live’ and ‘Neutral’ mainssupply leads are fused). These fuses can beremoved and replaced by hand. ALWAYSreplace the fuse by ones of the correct values shown below:

For 230V, 50Hz - T1A For 120V, 60Hz - T1.6A

4) Refit the base and four securing screws.

5) It is advisable to perform a ‘PAT’ (PortableAppliance Test) electrical safety test, orequivalent, before the SMP10 is put back intooperation.

For a comprehensive list of parts and a ServiceManual required by service engineers conductinginternal repairs, please contact the TechnicalService Department of Barloworld Scientific Ltd.quoting both the model and serial number.

Only spare parts supplied or specified byBarloworld Scientific Ltd. or its agents should beused. Fitting of non-approved parts may affectthe performance and safety features designedinto the instrument.

If in any doubt, please contact the TechnicalService Department of Barloworld Scientific Ltd.or the point of sale.

Barloworld Scientific Ltd. Stone, Staffordshire ST15 0SA United KingdomTel: +44 (0) 1785 812121 Fax: +44 (0) 1785 813748 e-mail [email protected]

4

Warranty

Barloworld Scientific Ltd. warrants this instrumentto be free from defects in material andworkmanship, when used under normallaboratory conditions, for a period of three (3)years. In the event of a justified claim BarloworldScientific will replace any defective component orreplace the unit free of charge.This warranty does NOT apply if damage iscaused by fire, accident, misuse, neglect,incorrect adjustment or repair, damage caused byincorrect installation, adaptation, modification,fitting of non-approved parts or repair byunauthorised personnel.

Barloworld Scientific Ltd. Stone, Staffordshire ST15 0SA United KingdomTel: +44 (0) 1785 812121 Fax: +44 (0) 1785 813748 e-mail [email protected]

Technical Specification

Number of samples TwoTemperature range Ambient to 300°CTemperature resolution 1°CTemperature accuracy ±1°C of displayed temperatureDisplay Three digit LEDSensor PT100Ramp rates 20°C / minute to plateau

2°C /minute to meltDimensions (WxDxH) 160 x 220 x 170 mmNet weight 1.8 Kg

5

Français

Merci d’acheter ce produit de BarloworldScientific. Pour obtenir le bonfonctionnement de l’équipement, et pourvotre sécurité, lire avec attention lesinstructions ci-dessous avant l’utilisation.

Le matériel Barloworld Scientific est conçu pourfonctionner dans les conditions suivantes.

❖ Pour l’usage en intérieur seulement ❖ Utilisation dans une pièce bien aérée ❖ Température ambiante +5°C à +40°C ❖ Altitude inférieure à 2000m ❖ Humidité relative n’excédant pas 80% ❖ Fluctuations de l’alimentation électrique

n’excédant pas 10% de la valeur nominale ❖ Catégorie II IEC60364-4-443 de surtension ❖ Degré 2 IEC664 de pollution

Si l’équipement n’est pas utilisé de la façondécrite dans ce manuel les différentes fonctionsde l’appareil peuvent être altérées.

SET

START

STOP

MADE IN THE UK

SET

START

STOP

MADE IN THE UK

Figure 1

Enbase cee

Affichabetemperature

Panneaude controle

Loupe d’observation

Support tubeechantillon

Pieds anovibles

Nobe operatoire

Narche /Arret

6

Installation Électrique

CET ÉQUIPEMENT DOIT ÊTRE RELIE ÀLA TERRE

Avant le raccordement, s’assurer quel’alimentation électrique convient. Cetappareil exige une alimentation 230V, 50-60Hz, monophasé. La puissance est de 70W.

Une embase CEE est située à l’arrière du côtédroit de l’instrument pour le raccordement àl’alimentation électrique, (voir le schéma 1).L’instrument est fourni avec deux câbles secteuréquipés d’une prises CEE pour le raccordement àl’instrument. Sur un, se trouve une prise auxnormes anglaises et sur l’autre une prise deeuropéen 2P+T. Choisir le câble approprié pourvotre installation électrique et jeter l’autre.

Si ni l’un ni l’autre ne conviennent, vous devrezalors obtenir le bon câble localement. Si ce n’estpas possible, prendre celui avec la prise anglaise,la couper et la remplacer par cellecorrespondante au pays d’utilisation. Voir lafeuille d’instruction incluse pour le montage decette prise.

Si l’état du câble secteur exige son remplacementun câble de 1mm2 norme H05W-F relié à uneprise CEE 320 devra être employé.

N.B. Le câble anglais est protégé par un fusible10A monté dans la prise.

Le câble doit être relié à l’instrument AVANT leraccordement à l’alimentation électrique.

EN CAS DE DOUTE CONSULTER UNÉLECTRICIEN QUALIFIÉ

Description Générale

Le Stuart SMP10 a été conçu pour une sécurité etfacilité d’utilisation maximale. L’affichage digitaldonne la température choisie et mesurée avecexactitude et évitant ainsi l’utilisation d’unthermomètre à mercure en verre. Deuxéchantillons peuvent être examinéssimultanément. ls sont observés parl’intermédiaire d’une loupe ayant une luminositéexceptionnelle. Les pieds de réglage de l’appareilpermettent à l’appareil d’être positionné pour unconfort d’utilisation optimum. Le plein accès aubloc permet le nettoyage et l’entretien aisé.

Avant d’utiliser votre SMP10 pour lapremière fois :Une fois que l’unité est déballée, choisirl’étiquette d’instructions, adhésive, appropriée àla langue du pays d’utilisation. Coller l’étiquettesur le côté gauche de la face avant du SMP10.Appliquer l’étiquette en employant un objet platpour lisser les bulles d’air.

7

Principe deFonctionnement

L’appareil à point de fusion SMP10 a été conçupour donner des résultats rapides et précis. Les échantillons sont placés dans un tubecapillaire en verre, scellé à une extrémité, dans lebloc d’aluminium à l’intérieur de la chambre demesure. Ce bloc est chauffé et l’échantillon estobservé par l’objectif jusqu’à ce que lechangement d’état se produise. La températuredu point de fusion peut alors être facilementrelevée sur le grand affichage digital.

Afin d’éviter l’observation continuelle del’échantillon, le SMP10 est équipé d’une fonction“plateau”. Ceci permet de sélectionner unetempérature placée quelques degrés au-dessousdu point de fusion prévu. Le SMP10 chaufferaalors jusqu’à cette température très rapidement(20C° par minute) et la maintiendra jusqu’à ceque l’opérateur soit prêt à observer. Durant cettemontée en température, l’appareil ne nécessitepas de surveillance particulière.

Une fois la mesure commencée, le SMP10chauffera lentement (2C° par minute), de latempérature de plateau jusqu’à ce que la fusionse produise. Cette montée lente permet unedétermination précise des points de fusion.

Avant l’emploi 1. Placer l’unité sur une surface à niveau et

placer les pieds à l’arrière de l’instrument desorte que l’unité soit dans une positionoptimale pour l’observation.

2. Relier à l’alimentation électrique et mettre enfonctionnement à l’aide de I’interrupteur“Marche/Arrêt”.

3. La température réelle de la chambre demesure sera affichée et la chambre de mesuresera illuminée.

4. Votre SMP10 est maintenant opérationnel.

Détermination d’un point de fusion N.B. Si l’appareil a été utilisé récemment le blocpeut être trop chaud pour votre échantillon. Sic’est le cas, appuyer sur la touche “ARRÊT” etlaisser l’unité refroidir avant la mise en route de laprocédure suivante.

1. Préparer l’échantillon en plaçant un peu de cedernier dans l’extrémité d’un tube capillaireen verre

2. Choisir la température appropriée pour leplateau. Celle-ci devra êtreapproximativement 10C° au-dessous du pointde fusion prévu.

3. Vérifier que les 3 témoins de fonctionnementsont éteints. Sinon, appuyer sur la touche“ARRÊT”.

4. Appuyer et maintenir le bouton de sélection(la lumière de plateau clignotera). L’affichagedonnera alors la température courante deplateau. Lors de la première utilisation celle-cisera de 50C°. Celle-ci aura pu être remise àzéro par l’utilisateur précédent.

5. La température désirée de plateau peutmaintenant être sélectionnée en utilisant lestouches de déplacement haut ou bas pourobtenir celle exigée.

6. Relâcher le bouton, la nouvelle températurede plateau est maintenant affichée et toutesles lumières de fonction s’éteindront (leplateau peut être vérifié à tout moment lorsdu fonctionnement en appuyant etmaintenant le bouton de sélection. Cetteaction n’interférera dans le bonfonctionnement de l’appareil).

7. Insérer le tube par le côté du bloc dechauffage dans les orifices prévus à cet effet.Ceci peut être fait de l’un ou l’autre côté dubloc. Placer le tube de sorte qu’on puisseobserver clairement l’échantillon.Attention: Le bloc de chauffage peutêtre CHAUD

8

8. Appuyer sur la touche “MARCHE”. L’unitéchauffera rapidement jusqu’à la températurede plateau (la lumière de chauffage serailluminée - voir schéma 1).

9. Une fois que la température de plateau a étéatteinte la lumière de plateau sera illuminéecomme la lumière de chauffage - voir schéma 1.

N.B. À basses températures, le plateau peutêtre dépassé. Attendre jusqu’à ce que lalumière de plateau s’illumine avant decontinuer la procédure afin de s’assurer quela température est stabilisée.

10. Appuyer sur le bouton “MARCHE” ànouveau. Le bloc commencera à chaufferavec une pente préréglée de 2C° par minute(la lumière de plateau s’éteindra et leslumières de pente de chauffage s’illumineront- voir schéma).

11. Observer l’échantillon jusqu’à ce que la fusionse produise et noter la température affichée.

12. Après la fusion, appuyer sur la touche“ARRÊT”. Toutes les lumières de fonctions’éteindront et l’unité redescendra à latempérature ambiante.

13. La pression du bouton “MARCHE” à nouveauramènera l’unité à la température de plateauau lieu de l’ambiant. La lumière de chauffages’illuminera même si la température est au-dessus du plateau, mais l’appareil refroidira.

Nettoyage et Entretien

AVERTISSEMENT: S’assurer que l’appareiln’est plus alimenté et refroidit avantd’entamer le nettoyage ou l’entretien.

Nettoyage Nettoyer périodiquement l’instrument en utilisantun tissu humide et une solution détergentedouce. Ne pas employer de produits abrasifs.

Des tubes capillaires cassés peuvent être enlevésdu bloc simplement en les poussant à travers

avec un morceau de fil de fer ou d’un outilsemblable.

Pour l’accès au bloc pour un nettoyage pluscomplet le capot supérieur doit être enlevé.

1. Enlever les 3 vis de retenue et enlever lecapot.

2. Desserrer la vis maintenant la plaquemétallique mais ne pas l’enlevercomplètement.

3. Pousser la plaque sur le côté.

4. La fenêtre de verre au-dessus du bloc peutmaintenant être enlevée.

Entretien N’importe quelles réparations ou remplacementdes pièces DOIVENT être entrepris par dupersonnel convenablement qualifié.

Pour une liste complète de pièces et un manueld’entretien technique, requis par des techniciensconduisant des réparations internes, entrer encontact avec le service après vente technique deBarloworld Scientific France en précisant lemodèle et le numéro de série.

Seules les pièces de rechange fournies ouindiquées par Barloworld Scientific France ou sesrevendeurs doivent être employées. L’utilisationde pièces non-approuvées peut affecter lefonctionnement et la sécurité de l’instrument.

En cas de doute, contacter avec le servicetechnique de Barloworld Scientific France ouvotre revendeur.

Barloworld Scientific France SASZI du Rocher Vert - BP 7977793 Nemours Cedex FranceTél: +33 1 64 45 13 13 Fax: +33 1 64 45 13 00 e-mail: [email protected]

9

Garantie

Barloworld Scientific France garantit cet appareilde tout défaut de fabrication ou de montagepour une utilisation normale en laboratoire et cedurant trois (3) ans. En cas de défaillance,Barloworld Scientific France s’engage à remplacergratuitement la pièce défectueuse ou l’appareil sice dernier était déclaré irréparable.

Cette garantie ne s’applique pas si les dommagessont dus à un incendie, un accident, uneinondation, une négligence ou une utilisationinadéquate. La garantie ne s’applique pas nonplus si l’appareil n’a pas été installé correctement,réparé par une personne non qualifiée ou modifiéà l’aide de pièces détachées ne provenant pas dela société Barloworld Scientific France.Cette garantie ne modifie pas les statuts et droitsdes échanges commerciaux.

Barloworld Scientific France SASZI du Rocher Vert - BP 7977793 Nemours Cedex FranceTél: +33 1 64 45 13 13 Fax: +33 1 64 45 13 00 e-mail: [email protected]

10

Vi ringraziamo per avere acquistato questoprodotto Barloworld Scientific. Per ottenerela migliore prestazione da questoapparecchio, e per la Vostra sicurezza, Vipreghiamo di leggere attentamente questeistruzioni prima dell’uso.

L’apparecchio è stato progettato per unfunzionamento nelle seguenti condizioni:

❖ Da usarsi solo all’interno❖ Da usarsi in un’area ben ventilata❖ In un campo di variazione di temperatura da

+5°C a +40°C❖ Ad un’altitudine massima di 2000 metri❖ Con una umidità relativa non superiore a 80%❖ Con fluttuazioni dell’alimentazione da rete

non superiori a 10%❖ Categoria di sovratensione II CEI60364-4-443❖ Grado di contaminazione 2 CEI664

Se l’apparecchio non è usato come specificato nelpresente manuale, la protezione offertadall’apparecchio stesso può essere ridotta.

Italiano

SET

START

STOP

MADE IN THE UK

SET

START

STOP

MADE IN THE UK

Figure 1

Alimentazione

Displaytemperatura

Pannellocomandi

Visore

Blocco portacampioni

Appoggioregolabile

Etichettaistruzioni

Interruttoreon / off

11

Installazione Elettrica

L’APPARECCHIO DEVE ESSERECOLLEGATO A TERRA.

Prima della connessione, assicurarsi che lalinea di alimentazione sia idonea. Questoapparecchio necessita di un’alimentazione da230V, 50-60Hz, monofase. La potenza diassorbimento è di 70W.

Sulla parte posteriore dell’apparecchio è presenteuna presa CEI per la connessione all’impianto dialimentazione (fig.1). Ogni unità viene fornita condue cavi di alimentazione dotati di spina CEI perla connessione dell’apparecchio alla lineaelettrica. Un cavo è dotato di spina “Inglese” a 3pin, l’altro ha una spina tipo “Shuko” a 2 pin.Scegliere il cavo più adatto per la connessione escartare l’altro.

In caso i cavi non fossero adatti all’uso, sarànecessario provvedere alla loro sostituzione conmodello alternativo. E’ possibile eventualmentesostituire la spina, se i modelli forniti non fosseroadatti alle esigenze, con altro tipo,semplicemente tagliando la spina esistente,sostituendola con altro tipo. Ulteriori istruzionimostrano come eseguire questa procedura. Incaso di sostituzione del cavo di alimentazione,sarà necessario utilizzare un cavo da 1mm2

codificato come H05W-F e connesso con spinaeuropea CEI320.

N.B.: Il cavo di alimentazione inglese è protettoda un fusibile di 10A montato sulla spina. Il cavo di alimentazione deve essere connessoall’apparecchio prima di essere collegatoall’impianto elettrico.

IN CASO DI DUBBIO, CONSULTARE UNELETTRICISTA QUALIFICATO.

Descrizione Generale

L’apparecchio Stuart SMP10 è stato progettatoper essere utilizzato in condizioni di massimasicurezza e semplicità d’uso. La temperatura vieneimpostata, misurata e visualizzata in via digitale,garantendo l’accuratezza ed evitando l’uso ditermometri di vetro a mercurio. Sarà possibileesaminare due capillari campionecontemporaneamente. I campioni vengonoosservati nitidamente tramite una lente diingrandimento illuminata, e i piedini di appoggioregolabili permettono la scelta del miglioreangolo di osservazione. Il completo accesso alblocco riscaldante permette una facile pulizia emantenimento dell’apparecchio.

Prima dell’usoUna volta aperto l’imballo del Vostro apparecchio,scegliete l’etichetta adesiva contenente leistruzioni da applicare all’apparecchio, nellalingua desiderata. Successivamente applicatel’etichetta sulla parte sinistra del pannello deicomandi.

Principi di utilizzo

I campioni da fondere devono essere preparati incapillari di vetro chiusi a un’estremità,successivamente introdotti nel blocco riscaldante.Mentre il blocco si scalda, il campione vieneosservato attraverso la lente fino alla fusione. Latemperatura di fusione verrà visualizzata suldisplay digitale.

Per evitare la continua osservazione delcampione, l’apparecchio SMP10 è stato dotato diuna funzione di “picco”. Ciò permettel’impostazione di una temperatura di pocoinferiore a quella prevista per la fusione (se nota).

Raggiunta questa temperatura, l’apparecchio lamanterrà costante fino a che l’utilizzatore siapronto per l’osservazione. Cominciata questaseconda fase, l’apparecchio riscalderà moltolentamente (2°C al minuto) partendo dallatemperatura “picco” fino alla fusione delcampione.

Prima dell’uso1. Sistemare l’apparecchio su una superficie piana

rigida ed estendere i piedi di appoggio fino allivello di angolazione desiderato.

2. Connettere l’apparecchio all’alimentazioneelettrica e metterlo in funzione con l’appositopulsante di accensione/spegnimento.

3. Il display mostra l’attuale temperatura delblocco, ora illuminato.

Misurazione del punto di fusioneN.B. Se l’unità è stata usata di recente, il bloccopotrebbe essere già caldo. In questo caso premereil pulsante Stop e attendere il raffreddamento delblocco.

1. Preparare il campione introducendo la polverenel capillare di vetro.

2. Decidere se impostare una temperatura“picco”. E’ sufficiente impostare unatemperatura di 10°C inferiore al punto difusione previsto (se noto).

3. Verificare che le spie luminose di funzionesiano spente, altrimenti premere Stop.

4. Premere e mantenere premuto il tasto Set (laspia di “picco” lampeggia). Il display mostraora la temperatura di picco (la prima volta saràdi 50°C).

5. Si può ora impostare la nuova temperatura dipicco, utilizzando i tasti freccia in aumento oin diminuzione rispetto al display.

6. Rilasciare il pulsante Set: ora la nuovatemperatura di picco è visualizzata, e le spie difunzione sono spente (la temperatura di piccopuò essere controllata in ogni momento,premendo il tasto Set. Ciò non interferisce nelriscaldamento del blocco).

12

7. Inserire il capillare dalla parte laterale delblocco, attraverso gli appositi fori. Perconvenienza ciò può essere fatto da entrambii lati. Osservare attraverso la lente eposizionare il capillare (delicatamente) fino adavere la migliore osservazione.

Attenzione: il blocco potrebbe essere giàcaldo!

8. Premere Start. L’apparecchio riscalderàvelocemente fino alla temperatura di piccoimpostata (la spia di riscaldamento è accesa -fig.1).

9. Raggiunta la temperatura di picco, siaccenderà una seconda spia - fig.1.

N.B.: Se la temperatura di picco è bassa,potrebbe verificarsi una fluttuazione ditemperatura, perciò è meglio attenderel’accensione della spia di picco, che assicurala stabilità della temperatura impostata.

10. Premere nuovamente il tasto Start. Il bloccoviene ora scaldato a 2°C al minuto (la spia dipicco si spegne, le spie di rampa eriscaldamento restano accese - fig.1.

11. Osservare attentamente il campione fino almomento della fusione e registrare la relativatemperatura sul display.

12. Conclusa la fusione della sostanza campione,premere Stop. Tutte le spie luminose sispengono e l’apparecchio torna allatemperatura ambiente.

13. Premendo Start prima dell’effettivoraffreddamento del blocco, l’apparecchiotornerà automaticamente alla temperatura dipicco precedentemente impostata. La spialuminosa di riscaldamento si accenderà pur sel’apparecchio è in fase di raffreddamento.

13

Pulizia e manutenzione

ATTENZIONE: Assicurarsi che l’apparecchiosia scollegato all’impianto di alimentazioneelettrico e che il blocco sia sufficientementeraffreddato prima di procedere a qualsiasioperazione di pulizia o manutenzione.

Pulizia: pulire periodicamente l’apparecchiousando un panno morbido e una soluzionedetergente leggera. Non utilizzare agentidetergenti aggressivi o corrosivi. I capillarieventualmente rotti all’interno del bloccopossono essere facilmente eliminati spingendolicon un filo rigido od oggetti similari. Per ilcompleto accesso al blocco riscaldante ènecessario rimuovere il coperchio protettivo:

1. Rimuovere le 3 viti di sicurezza e sollevare ilcoperchio.

2. Svitare la vite che assicura il piatto di metallosenza rimuoverla completamente.

3. Spingere il piatto di metallo da una parte.

4. Ora si può rimuovere la protezione inpolicarbonato sopra il blocco.

Manutenzione: Ogni riparazione o sostituzionedi parti di ricambio DEVE necessariamente essereeffettuata da personale altamente qualificato.

Le seguenti parti di ricambio sono disponibilipresso il Vostro fornitore:Lampada per illuminazione del blocco. ESMP102(S)

Set di etichette per istruzioni multilingue. FSMP1010

Confezione da 2 piedi di appoggio regolabili. USMP10

Per una lista più completa di ricambi o manualedi servizio, contattare il Centro Tecnico dellaBarloworld Scientific Ltd. più vicino, specificandomodello e numero di serie. Sono autorizzate leoperazioni di sostituzione eseguite con parti diricambio originali Barloworld Scientific. L’utilizzodi parti non originali può compromettere lafunzionalità dell’apparecchio e rendere vane lemisure di sicurezza esistenti sull’apparecchio.

In caso di dubbio, contattare la BarloworldScientific Italia Srl, Via Alcide de Gasperi 5620077 Riozzo di Cerro al Lambro, Milano, ItaliaTel. 02/98230679 Fax 02/98230211.

Garanzia

La Barloworld Scientific Ltd. garantisce questoapparecchio come esente da difetti nei materiali ein fase di fabbricazione, se usato alle normalicondizioni di laboratorio, per un periodo tris (3)anni. In caso di reclamo giustificato, la BarloworldScientific sostituirà ogni componente difettoso ol’intero apparecchio, senza onere alcuno. Talegaranzia NON verrà applicata in caso di dannicausati da incendi, incidenti, uso non corretto,negligenza, riparazione non autorizzata,installazione non corretta, adattamenti nonautorizzati, modifiche non autorizzate,montaggio di parti non originali o eseguite dapersonale non autorizzato.

Barloworld Scientific Italia SrlVia Alcide de Gasperi 5620077 Riozzo di Cerro al LambroMilano ItaliaTel: +39 (0)2 98230679Fax: +39 (0)2 98230211 e-mail: [email protected]

14

Espanol˜

Gracias por haber adquirido un productoBarloworld Scientific. Para obtener lasmáximas prestaciones del equipo, y para suseguridad, por favor, lea detenidamenteestas instrucciones de funcionamiento antesde usar el aparato.

Este aparato ha sido diseñado para ser utilizadobajo las siguientes condiciones:

❖ Para usar en locales al abrigo de la intemperie❖ Para usar en locales bien ventilados❖ Condiciones de trabajo: temperatura

ambiente +5ºC a +40ºC❖ Altitud hasta 2.000m❖ La humedad relativa no excederá de 80%❖ Las fluctuaciones de la corriente no excederán

un 10% del valor nominal❖ Sobre-Voltaje categoría II IEC60364-4-443❖ Grado de contaminación 2 IEC664

Si el equipo no se usa de la manera descrita eneste manual, la protección proporcionada por elaparato puede no ser adecuada.

SET

START

STOP

MADE IN THE UK

SET

START

STOP

MADE IN THE UK

Figure 1

Conectar decorriente IEC

Indicadarde temperatura

Pauel de contral

Visore

Ouficios paramuestras

Patas plegables

Caratula frontal

BotonParo / Marcha

15

Instalación eléctrica

ESTE EQUIPO DEBER SER CONECTADOA UNA TOMA DE TIERRA.

Antes de conectar el aparato por favorasegurarse de que la toma de corriente esutilizable. El aparato requiere una corrientede 230V, 50Hz, monofásica. Potenciaconsumida 75W.

Hay un conector IEC en la parte trasera delinstrumento para enchufar a la corriente (verfigura 2). La unidad se suministra con dos cablescon conexión IEC para acoplar al instrumento.Uno es con clavija UK con tres bornes y el otro estipo “Shuko” con dos bornes y toma de tierrautilizable en el resto de Europa. Escoger el cableadecuado para su instalación eléctrica y descartarel otro.

Si ninguno de los conectores es adecuado para suinstalación eléctrica, desmonte el enchufe conconector UK y coloque el adecuado. Ver lasinstrucciones adjuntas de cómo proceder a estecambio.

Si se requiere cambiar el cable, debe colocarseuno con sección de 1mm2, con código deaislamiento H05W-F, y conector IEC 320 en unode sus extremos para la conexión a la unidad.

SI TIENE CUALQUIER DUDA, CONSULTE A UNELECTRICISTA CUALIFICADO

El cable debe ser insertado al instrumento ANTESde su conexión a la corriente.

Descripción General

El SMP10 ha sido diseñado para la máximaseguridad y facilidad de uso. La temperatura seselecciona, mide y visualiza digitalmente,asegurando la exactitud y sin necesidad deutilizar un termómetro de vidrio. Pueden medirsehasta dos muestras simultáneamente. Laobservación se realiza por medio de una lentemuy nítida ayudado por un sistema deiluminación; además unos pies regulablespermiten un óptimo ángulo de observación; todoello situado en un bloque de fácil acceso para sulimpieza y mantenimiento.

Antes de usar por primera vez su SMP10Una vez desempaquetado el aparato, seleccionarla etiqueta donde van impresas las instrucciones,dependiendo del idioma que se use: Español,Inglés, Italiano o Francés, y pegarlo en la parteizquierda del panel de control del SMP10,aplanándolo bien para evitar que quedenburbujas debajo de la etiqueta.

Principio delfuncionamiento

El Punto de fusión SMP10 ha diseñado parapoder obtener unos resultados precisos y rápidosa la vez que, con gran facilidad en su uso.

Las muestras para la determinación del punto defusión se colocan en un tubo capilar, cerrado poruno de sus extremos, el cual se coloca en uno delos orificios del bloque de aluminio de la cámara.Este bloque es calentado y la evolución de lamuestra observada a través del visor con lupa,hasta el punto de fusión de la misma. Latemperatura del punto de fusión puedeobservarse fácilmente en el indicador digital.

Para evitar una larga espera en la determinacióndel punto de fusión, el SMP10 se ha equipadocon la función “meseta”. Esto permite fijar unatemperatura de inicio unos pocos grados pordebajo del valor esperado. El SMP10 alcanzarárápidamente dicha temperatura (20ºC/min) y

16

permanecerá estable manteniendoindefinidamente y con toda seguridad, latemperatura de “meseta”, en espera de que eloperador quiera comenzar a determinar el puntode fusión de la muestra.

Una vez que la medición ha comenzado, elSMP10 calentará con una rampa de temperaturafija de 2ºC/min, desde la temperatura de la“meseta” hasta que se observe la fusión de lamuestra. Esta pendiente de sólo 2ºC/min,consigue que el valor medido de punto de fusiónsea muy preciso.

Antes de UsarColocar la unidad en un sitio firme y nivelado,extender los pies, que están plegados en la partetrasera, para dejar el aparato en un ánguloconveniente de visión.

Enchufar el cable a la corriente eléctrica, yposteriormente poner en marcha el aparato pormedio del interruptor on/off.

La temperatura a la que esté el bloque dealuminio será mostrada en el display con tresdígitos, y la cámara se iluminara por medio deuna lámpara.

Medición del Punto de Fusión.Nota. Si la unidad acaba de ser usada, el bloquede aluminio de la cámara, puede estar demasiadocaliente para su muestra, debe en este caso,pulsar el botón STOP y esperar a que se enfríe,antes de proceder.

1. Introducir una pequeña cantidad de muestraen el final de un tubo capilar.

2. Escoger la temperatura de “meseta”. Éstadebe estar unos 10ºC por debajo de latemperatura de punto de fusión esperada.

3. Las tres luces de función deben esténapagadas, si no, pulsar la tecla STOP.

4. Presionar y mantener el botón SET (la luz dela función “meseta” destellará); el displayindicará ahora el último valor programado detemperatura de meseta, (por defecto laprimera vez indica 50ºC).

5. Introducir el valor que se desee por pulsaciónde las teclas de subida o bajada.

6. Dejar de presionar el botón SET. El nuevovalor de “meseta” está ahora memorizado, yla luz apagada (éste valor puede sercomprobado en cualquier momento,simplemente pulsando y soltando la teclaSET). Esta acción no interfiere en nada elnormal funcionamiento del aparato.

7. Insertar el capilar con la muestra en el bloquede calefacción, mirando simultáneamente porel visor, para centrar el capilar. El capilarpuede entrarse tanto desde el lado izquierdocomo el derecho del bloque de aluminio.Puede enfocarse para una visión óptimaajustando la altura del ocular del visor.

8. Pulsar la tecla START. La unidad se calentarárápidamente hasta llegar a la temperatura de“meseta”. (La luz de calentamiento seiluminará, ver fig 1.)

9. Una vez que la temperatura de “meseta”haya sido alcanzada, la luz de “meseta” seiluminará, además de la luz de calentamiento– ver fig 1.

NOTA: Un valor muy bajo en temperatura de“meseta” puede producir que se sobrepasetemporalmente el valor programado, Esperarhasta que la luz de “meseta” esté iluminadapara proceder, y así asegurarse que latemperatura permanezca estable.

10. Pulsar nuevamente la tecla START, el bloquecomenzará a calentar a partir de latemperatura de meseta a razón de 2ºC/min(La luz de “meseta” se apagará y las decalentamiento y rampa se iluminarán).

17

11. Observar el comportamiento de la muestra através del visor, hasta ver que se funde.Anotar la temperatura que muestra en esemomento el display.

Después de anotar la temperatura, pulsar latecla ”STOP” y todas las luces de función seapagarán y la unidad se irá enfriando hastatemperatura ambiente.

12. Presionando nuevamente la tecla START, launidad vuelve a la programación detemperatura de “meseta” en lugar de latemperatura ambiente quedando la luz decalentamiento encendida, por si se quierevolver a repetir la determinación, o bien sepuede volver al punto 4, para programar unnuevo valor.

Limpieza & Mantenimiento

ATENCION: Asegurarse que la unidad estádesconectada de la electricidad y se haenfriado, antes de realizar cualquier acciónde limpieza o mantenimiento.

LimpiezaLimpiar periódicamente el instrumento con unagamuza suave utilizando una solución jabonosaneutra. No deben usarse estropajos o agentesabrasivos para limpiar.

Los capilares que se hayan podido romper,pueden ser extraídos del bloque, simplementehaciendo pasar otro capilar o un alambre finotransversalmente.

Para acceder al bloque de calentamiento debedesmontarse la tapa superior.

1. Quitar los protectores de tornillos de la tapa 2. Aflojar el tornillo que sujeta la placa metálica,

sin quitarla del todo 1.3. Colocar la placa hacia un lado4. La ventanilla de cristal en el fondo del

bloque, puede ahora ser extraída.

MantenimientoCualquier reparación o reemplazamiento depiezas de recambio DEBE sólo ser realizada porpersonal qualificado.

Para una lista más exhaustiva de piezas derecambio, por favor contactar con elDepartamento Técnico de Barloworld ScientificLtd, indicando el modelo y nº de serie.

Sólo deben utilizarse recambios originalessuministrados por Barloworld Scientific o susagentes autorizados. La colocación de recambiosno originales, puede afectar a las prestaciones ycaracterísticas de seguridad del instrumento.Si tiene cualquier duda, o para recibir el manualtécnico, por favor contactar con el DepartamentoTécnico de Afora S.A.

18

Garantía

Barloworld Scientific Ltd, garantiza que esteinstrumento está libre de defectos en losmateriales y fabricación, siempre que el aparatose use en condiciones normales de laboratorio,por un periodo de tres (3) años. Si aparece noobstante cualquier defecto justificado, BarloworldScientific reemplazará el componente defectuososin cargo.

Esta garantía NO es aplicable sí el daño escausado por fuego, accidente, mal uso,negligencia, ajuste o reparación incorrecta, roturapor instalación incorrecta, adaptación omodificación, colocación de recambios nooriginales, o reparación por personal noautorizado.

Afora S.A.Calle Aribau 24008006 BarcelonaSpainTel: +343 93-306 98 00Fax: +343 93-306 98 23e-mail: [email protected]

Especificaciones técnicas

Número de muestras DosRango de temperatura Ambiente a 300°C Resolución 1°CExactitud ±1%Display Tres dígitosSensor PT100Rampas 20°C / minuto para temperatura de “meseta”

2°C /minuto para punto de fusiónDimensiones (AnxAlxFo) 160 x 170 x 220 mmPeso Neto 1,8 Kg Requerimientos

19

Deutsch

Wir bedanken uns für den Kauf diesesBarloworld Scientific Produkts. Lesen Siebitte vor dem Gebrauch dieseBedienungsanleitung gründlich durch, umdas Gerät optimal nutzen zu können.

Diese Gerät ist für den Einsatz unter folgendenBedingungen ausgelegt:

❖ Nur für den Gebrauch in Innenräumen❖ In einem gut durchlüfteten Bereich aufstellen❖ Umgebungstemperatur +5°C bis +40°C❖ Max. Höhe: 2000 m❖ Relative Luftfeuchte nicht über 80%❖ Stromversorgungsschwankungen nicht über

>10%❖ Überspannungsklasse II IEC60364-4-443❖ Verschmutzungsgrad 2 IEC664

Wenn das Gerät nicht entsprechend derBedienungsanleitung eingesetzt wird, können dieSchutzfunktionen des Gerätes beeinträchtigtwerden.

SET

START

STOP

MADE IN THE UK

SET

START

STOP

MADE IN THE UK

Abbildung 1

IEC Netzanschluß

Temperaturanzeige

Bedienfläche

Sichtfenster

Halter fürProbenröhrchen

Aufstellfüße

Fläche fürBedienungshinweise

Netz Ein / Aus

20

Elektrischer Anschluß

DIESES GERÄT MUSS GEERDETWERDEN

Überprüfen sie bitte vor dem Anschluß, daßdie richtige Stromversorgung vorhanden ist.Dieses Gerät muß an 230V, 50-60Hz,Einphasenwechselstrom angeschlossenwerden. Die Leistungsaufnahme beträgt 70 W.

An der rechten Geräteseite befindet sich eingenormter IEC Anschluß für das Netzkabel, (sieheAbbildung 1). Das Gerät wird mit zweiNetzkabeln mit IEC Anschluß geliefert. Das eineNetzkabel ist für den Anschluß in Großbritanniengedacht und besitzt 3 Anschlußstifte, währenddas andere Kabel mit einem Schuko-Steckerausgestattet ist. Wählen Sie das entsprechendeNetzkabel für Ihren Einsatzort. Das andere Kabelkann dann entsorgt werden.

Sollten beide Kabel ungeeignet sein, müssen Siesich das entsprechende Kabel vor Ort besorgen.Ist dies nicht möglich so kann ein anderer Steckerauch an das für Großbritannien gedachte Kabelmontiert werden. Das beiliegende Hinweisblattenthält Anweisungen zum Montieren einesanderen Steckers.

Falls das Netzkabel einmal ersetzt werden muß,sollten Sie ein Kabel mit 1mm2 Querschnitt(H05W-F) und IEC 320 Stecker verwenden.Anm.: Das Netzkabel besitzt eine in den Steckereingebaute 10A Sicherung.

Das Netzkabel muß VOR dem Anschluß an dieStromversorgung zuerst in das Gerät eingestecktwerden.

IM ZWEIFELSFALL WENDEN SIE SICH BITTEAN EINEN ELEKTRIKER

Allgemeine Beschreibung

Das Stuart SMP10 wurde für höchste Sicherheitund Bedienungsfreundlichkeit konzipiert. DieTemperatur wird gewählt, gemessen und dannauf einer Digitalanzeige genau dargestellt, so daßein Glasthermometer entfällt. Es können zweiProben gleichzeitig geprüft werden. DieBeobachtung erfolgt durch ein leicht sichtbaresVergrößerungsglas mit eingebauter Beleuchtung.Durch die Aufstellfüße kann das Gerät auf denbesten Betrachtungswinkel eingestellt werden.Die Halterung ist gut zugänglich, um dieReinigung und Wartung zu erleichtern.

Vor dem ersten Gebrauch des SMP10Nach dem Auspacken den Geräts wählen Siebitte die entsprechende selbsthaftendeBeschilderung aus dem mitgeliefertenSprachensatz. Dann die Folie auf der Rückseiteabziehen und das Schild auf der linken Seite aufder Gerätevorderseite anbringen. Das Schildvorsichtig aufkleben und etwaige Luftblasen miteinem flachen Gegenstand wegstreichen.

Funktionsweise

Der Schmelzpunktapparat SMP10 wurde soentworfen, daß sowohl eine schnelle und genaueErgebnisermittlung, als auch eine möglichsteinfache Bedienung möglich ist.

Die Schmelzpunktproben werden in einKapillarröhrchen gegeben, an einem Endeversiegelt und in die Aluminiumhalterung in derProbenkammer eingesetzt. Diese Halterung wirddann aufgeheizt und die Probe mit Hilfe desVergrößerungsglases kontrolliert, bis dieSchmelzung stattfindet. DieSchmelzpunkttemperatur kann dann leicht vonder großen LED-Anzeige abgelesen werden.Damit man die Probe nicht ständig beobachtenmuß, besitzt das SMP10 eine “Plateau” Funktion.Damit läßt sich die Temperatur auf ein paar Gradunter dem zu erwartenden Schmelzpunkteinstellen. Das SMP10 heizt sich dann sehrschnell auf diese Temperatur auf (20°C proMinute) und hält diese Temperatur solange, bisder eigentliche Meßvorgang stattfinden soll.

21

Während dieses Vorgangs kann das Gerätbedenkenlos unbeaufsichtigt sein.Sobald dann der Meßvorgang ausgelöst wird,heizt sich das SMP10 langsam (mit 2°C proMinute) weiter auf, bis der Schmelzpunkt erreichtwird. Durch diese langsame Aufheizungsrate läßtsich der Schmelzpunkt sehr genau bestimmen.

Vor dem Gebrauch1. Das Gerät auf eine feste, ebene Fläche stellen

und die Füße hinten am Gerät so einstellen,daß ein guter Betrachtungswinkel gegebenist.

2. Gerät an die Stromversorgung anschließenund mit dem Ein/Aus-Schalter anschalten.

3. Es wird nun die aktuelle Halter-Temperaturauf der dreistelligen LED-Anzeige dargestellt.Gleichzeitig schaltet sich die Beleuchtung derProbenkammer ein.

Messen des SchmelzpunktesAnm.: Falls das Gerät erst vor kurzem gebrauchtwurde, kann es sein, daß der Halter für dienächste Probe zu heiß ist. In diesem Fall dieStop-Taste drücken und das Gerät abkühlenlassen.

1. Eine kleine Menge der Probe in das Ende desKapillarröhrchens einsetzen.

2. Eine geeignete Plateau-Temperatur wählen.Diese sollte etwa 10°C unter dem zuerwartenden Schmelzpunkt der jeweiligenProbe liegen.

3. Kontrollieren, ob alle 3 Funktionsleuchten aussind. Andernfalls die Stop-Taste drücken.

4. Die Taste “Set” drücken und halten (diePlateau-Leuchte blinkt auf). Auf der Anzeigeerscheint nun die gegenwärtige Plateau-Temperatur. Beim ersten Einschalten beträgtdiese 50°C. Falls das Gerät jedoch vorherbereits benutzt wurde, kann auch eineandere Temperatur eingestellt sein.

5. Die gewünschte Plateau-Temperatur kannnun mit Hilfe der Pfeiltasten und der Anzeigeje nach Bedarf eingestellt werden.

6. Die Taste “Set” wieder loslassen. Die neuePlateau-Temperatur ist nun eingestellt, alleFunktionsleuchten gehen aus. (Die Plateau-Einstellung kann jederzeit durch Drücken undHalten der Taste “Set” kontrolliert werden,ohne daß dadurch der Gerätebetriebbeeinflußt würde).

7. Das Röhrchen in eines der Löcher desHeizblocks einsetzen. Dies ist von beidenSeiten aus möglich. Durch dasVergrößerungsglas schauen und dasRöhrchen so positionieren, daß die Probedeutlich zu sehen ist.

8. Die Taste “Start” drücken. Das Gerät heiztsich schnell auf die Plateau-Temperatur auf(die Heizleuchte ist an - siehe Abbildung 1).

9. Nach Erreichen der Plateau-Temperatur sindsowohl die Plateau-Leuchte als auch dieHeizleuchte aktiviert - siehe Abbildung 1. Anm.: Bei niedrigen Plateau-Temperaturenkann es zunächst zu einem Überschreiten dereingestellten Temperatur kommen. Daherwarten, bis das Plateau-Licht aufleuchtet, umsicher zu sein, daß sich die Temperaturstabilisiert hat.

10. Erneut die Taste “Start” drücken. DieHalterung heizt sich nun mit der festgelegtenAnstiegstemperatur von 2°C pro Minute auf.(Dabei geht die Plateau-Leuchte aus, währenddie Leuchten für Anstiegsrate und Heizungaktiviert sind - siehe Abbildung 1).

11. Die Probe beobachten, bis die Schmelzungstattfindet und dann die Temperatur von derDigitalanzeige ablesen.Nach dem Schmelzen die Taste “Stop”drücken. Alle Funktionsleuchten gehen ausund das Gerät kühlt sich auf dieUmgebungstemperatur ab.

12. Durch erneutes Drücken der Taste Start kehrtdas Gerät auf die Plateau-Temperatur zurück.Das Heizlampe euchtet auf, selbst wenn dieTemperatur über dem Plateau liegt und sichdas Gerät in Wirklichkeit abkühlt.

22

Reinigung & Wartung

VORSICHT: Vor allen Wartungs- oderReinigungsarbeiten darauf achten, daß dasGerät von der Stromversorgung getrennt istund sich ausreichend abgekühlt hat.

ReinigungDas Gerät in regelmäßigen Abständen mit einemfeuchten Tuch und einem mildenReinigungsmittel reinigen. Keine ätzenden oderScheuermittel zur Reinigung verwenden.Zerbrochene Schmelzpunktröhrchen können miteinem Stück Draht oder ähnlichem einfach durchden Halter hindurchgeschoben werden.Bei einer ausführlicheren Reinigung des Blocksmuß zuerst die Abdeckung der Probenkammerabmontiert werden:1. Die 3 Halteschrauben lösen und die

Abdeckung abnehmen.2. Die Schraube der Metallplatte lösen aber

nicht ganz herausnehmen.3. Die Platte zur Seite schieben.4. Nun kann das Glasfenster oben auf dem

Halter herausgenommen werden.

WartungEtwaige Reparatur- oder AustauscharbeitenMÜSSEN von entsprechend qualifiziertemFachpersonal vorgenommen werden.Eine ausführliche Teileliste und eineWartungshandbuch sind über die TechnischeAbteilung der Barloworld Scientific Ltd. erhältlich.Dabei bitte sowohl die Model-Nr. als auch dieSerien-Nr. angeben.Es dürfen nur die von Barloworld ScientificLtd.gelieferten bzw. vorgeschrieben Teileverwendet werden. Durch nicht genehmigteKomponenten können sowohl die Leistung, alsauch die Sicherheitsfunktionen des Gerätsbeeinträchtig werden.Im Zweifelsfall wenden Sie sich bitte an dieTechnische Abteilung der Firma BarloworldScientific oder an Ihren Händler.

Gewährleistung

Barloworld Scientific Ltd. gewährleistet für einenZeitraum von drei (3) Jahren, daß dieses Gerätbei Einsatz unter normalen Laborbedingungenvon Material und Verarbeitungsfehlern frei ist. ImFalle einer berechtigten Reklamierung ersetztBarloworld Scientific kostenlos alle defekten Teilebzw. das gesamte Gerät.

Diese Garantie gilt NICHT für folgendeSchädensfälle: Brand, Unfall, Mißbrauch,Vernachlässigung, unsachgemäße Einstellungoder Reparatur, durch falsche Installationverursachte Schäden, Umbau, Einbauunzulässiger Teile oder Reparatur durch nichtautorisiertes Personal.

Barloworld Scientific Ltd. Stone, Staffordshire ST15 0SA United KingdomTel: +44 (0) 1785 812121 Fax: +44 (0) 1785 813748 e-mail [email protected]

23

Technische Daten

Anzahl der Proben ZweiTemperaturbereich 300°C Umgebungstemp. bis Temperaturauflösung 1°CTemperaturgenauigkeit ±1%Anzeige Dreistellige LEDFühler PT100Anstiegsraten 20°C / Minute bis Plateau

2°C /Minute bis SchmelzungAbmessungen (BxTxH) 160 x 220 x 170mmNettogewicht Kg 1,8

These products meet the relevant ECharmonised standards for radio frequencyinterference and may be expected not to

interfere with, or be affected by, other equipment withsimilar qualifications. We cannot be sure that otherequipment used in their vicinity will meet these standards

and we cannot guarantee that interference will not occurin practice. Where there is a possibility that injury,damage or loss might occur if equipment malfunctionsdue to radio frequency interference, or for general advicebefore use, please contact the Technical ServiceDepartment of Barloworld Scientific Ltd.

INSPECTION REPORT

MODEL SMP10

ELECTRICAL SAFETY

1. Earth continuity ❏2. Insulation ❏3. Flash test ❏

FUNCTIONAL

1. Indicators ❏2. Temperature control ❏3. Visual acceptance ❏

QUALITY CONTROL INSPECTOR

✓

✓

✓

✓

✓

✓

Barloworld Scientific LtdBeacon Road Stone Staffordshire ST15 0SAUnited KingdomTel: +44 (0)1785 812121 Fax: +44 (0)1785 813748 www.barloworld-scientific.com

Barloworld Scientific France SASZI du Rocher Vert - BP 7977793 Nemours Cedex FranceTel: +33 1 64 45 13 13 Fax: +33 1 64 45 13 00 e-mail: [email protected]

Barloworld Scientific Italia SrlVia Alcide de Gasperi 5620077 Riozzo di Cerro al LambroMilano ItaliaTel: +39 (0)2 98230679Fax: +39 (0)2 98230211 e-mail: [email protected]

Barloworld Scientific US Ltd 350 Commerce Drive Rochester NY 14623 USATel: (800) 828-6595 Fax: (585) 334-0241www.dynalabcorp.com

Afora S.A.Calle Aribau 24008006 Barcelona SpainTel: +343 93-306 98 00Fax: +343 93-306 98 23e-mail: [email protected]

Scientific

Related Documents