MAKALAH PREVENTIVE MAINTENANCE DISUSUN OLEH : DARRYL VALENTINO SUMIRANA ( 209131008 )

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

MAKALAH

PREVENTIVE MAINTENANCE

DISUSUN OLEH :

DARRYL VALENTINO SUMIRANA

( 209131008 )

POLITEKNIK MANUFAKTUR NEGERI BANDUNG

PREFACE

Praises for Allah SWT. has given his blessing and the gift to us so we managed to finish

this paper is timely entitled "Preventive Maintenance".This paper contains information

about understanding preventive maintenance or more specifically discuss the application

of preventive maintenance, characteristics and application of preventive maintenance,this

paper is expected to provide information to us after learning all about preventive

maintenance.

We realize that this paper is far from perfect, therefore criticism and suggestions from all

parties as constructive is always our hope for the perfection of this paper.

The final word, we say thank you to a party all who have participated in the preparation

of this paper from beginning to end, may Allah Almighty always be pleased with all our

efforts, amin.

Bandung, 20 Juli 2012

Writer

DAFTAR ISI

Pendahuluan ............................................................................................... 1

Daftar isi ..................................................................................................... 2

Chapter 1 : introduction .............................................................................. 3

Chapter 2 : Basic Theory ............................................................................ 8

Bab 3 : Pembahasan .............................................................................. 16

Bab 4 : Kesimpulan dan Saran .............................................................. 26

Daftar Pustaka ............................................................................................. 28

CHAPTER I

INTRODUCTION

1.1 Background

British Standard Glossary of terms (3811:1993) defined maintenance as: the combination

of all technical and administrative actions, including supervision actions, intended to retain an

item in, or restore it to, a state in which it can perform a required function. maintenance is a

set of organised activities that are carried out in order to keep an item in its best operational

condition with minimum cost acquired.

Bandung Polytechnic for manufacturing its self is one of the professional educational

institutions in Indonesia, as befits an educational institution, then it becomes an obligation for

Bandung Polytechnic for Manufacturing to provide supporting facilities in the educational

process and the production process. In the last decade, the need for Maintenance of a

company or industry, particularly in Polman with the activities of maintenance and regular

maintenance on a machine or tools, so that the machine can run well.

In this case, preventive maintenance became one of the most important maintenance

activities that students should do. The preventive maintenance program covered several

things such as :

Maintenance schedule of all types of machine that exist in POLMAN

Doing maintenance activities based on schedule board ( inspection, small repair,

medium repair, overhaul )

Trouble analysis and trouble repair

From those things above we can make a conclusion that preventive maintenance is one of the

most important maintenance activities and we should know about it.

1.2 Objective of the Study

The purpose of this activity report writing are:

1. Students understand the meaning of a engine maintenance, so as to minimize

the occurrence of damage to the machine that can inhibit the activities of education both and

production both.

2. Students can understand about the basics of maintenance, especially about preventive

maintenance.

3. Students are expected to master the sciences base and use of tolls can be applied in

preventive maintenance activities.

4. Students can take knowledge when the practice preventive maintenance and then sharing

for other students.

5. Students can working with the attention of safety factor for tools and human in the area

working

1.3 Scope of the Study

The report of this praktice is focused on:

a) Limitation of issues

Understanding the right prespective of maintenance and preventive maintenance

Improving knowledge about lubrication

Improving knowledge about calibration

Inspection of schaublin lathe machine

Inspection of aciera unviersal milling

Inspection of surface grinding machine

Repair the carriage bolt of lathe machine

Change the nut of aciera universal milling

Small repair of aciera universal milling

Lubrication for schaublin universal milling

Calibration for aciera universal milling

Levelling milling machine

b) Technical Collection of the data

Data obtained in the manufacture of this activity report sourced from:

• The Explanation of the instructor.

• reference books that suport about Preventive maintenance and the sciences of the

other maintenance.

• Browsing the internet.

• Discussions with the lecturers and the parties related to the process of making this

activity report.

• Taking pictures through the camera

1.4. Systematics of Writing

This report made by systematic to divided into four chapters, Including :

Chapter I is an introduction that describes the background, objectives and so on.

Chapter II is the basis of the theory, which explains about all things related to the

theory and the theory of Maintenance related with machinery, machine elements etc.

Chapter III is a discussion, which includes the discussion conducted at the preventive

maintenance, problem analysis and solution of problems.

Chapter IV is the conclusion, which is the conclusion of the maintenance foundry and

maintenance work practices and suggestions to make a change towards a better.

CHAPTER II

BASIC THEORY

2.1 Definitions of Maintenance

British Standard Glossary of terms (3811:1993) defined maintenance as: the

combination of all technical and administrative actions, including supervision actions,

intended to retain an item in, or restore it to, a state in which it can perform a required

function. maintenance is a set of organised activities that are carried out in order to keep an

item in its best operational condition with minimum cost acquired.

Activities of maintenance function could be either repair or replacement activities,

which are necessary for an item to reach its acceptable productivity condition and these

activities, should be carried out with a minimum possible cost.

2.2Maintenance History

1. In the period of pre-World War II, people thought of maintenance as an added cost to

the plant which did not increase the value of finished product. Therefore, the

maintenance at that era was restricted to fixing the unit when it breaks because it

was the cheapest alternative.

2. During and after World War II at the time when the advances of engineering and

scientific technology developed, people developed other types of maintenance, which

were much cheaper such as preventive maintenance. In addition, people in this era

classified maintenance as a function of the production system.

3. Nowadays, increased awareness of such issues as environment safety, quality of

product and services makes maintenance one of the most important functions that

contribute to the success of the industry. World-class companies are in continuous

need of a very well organised maintenance programme to compete world-wide.

2.3Maintenance Objectives

Maintenance objectives should be consistent with and subordinate to production

goals. The relation between maintenance objectives and production goals is reflected

in the action of keeping production machines and facilities in the best possible

condition.

Maximising production or increasing facilities availability at the lowest cost

and at the highest quality and safety standards.

Reducing breakdowns and emergency shutdowns.

Optimising resources utilisation.

Reducing downtime.

Improving spares stock control.

Improving equipment efficiency and reducing scrap rate.

Fix the equipment when it breaks

-Term terotechnology introduced.-Recognition of need to present equipment failures. -Models for preventive maintenance developed.

-Increased awareness of: -Environment -Safety -Quality-Need for reliable equipment.-Reduction in costs.

Pre-World War II Post-World War II 1980 Onwards

Time

Develo

pme

nt of M

ainte na

nce

Figure 2.2 Maintenance History(Adapted From Shenoy, Bhadury 1998)

Minimising energy usage.

Optimising the useful life of equipment.

Providing reliable cost and budgetary control.

Identifying and implementing cost reductions.

2.4Types of Maintenance

Run to Failure Maintenance (RTF)

Preventive Maintenance (PM)

Corrective Maintenance (CM)

Improvement Maintenance (IM)

Predictive Maintenance (PDM)

PLANT

M

AINTENANCE

Reduce Breakdowns

Reduce Downtime

Improving Equipment Efficiency

Improving Inventory Control

Implementing Cost Reduction

Maximising Production

Optimising Resources Utilisation

Optimising Useful Life of Equipment

Minimising Energy Usage

Providing Budgetary Control

Figure 2.3 Maintenance Objectives

2.5.1 Run to Failure Maintenance (RTF)

The required repair, replacement, or restore action performed on a machine or a facility after the occurrence of a failure in order to bring this machine or facility to at least its minimum acceptable condition. It is the oldest type of maintenance. It is subdivided into two types:

– Emergency maintenance: it is carried out as fast as possible in order to bring a failed machine or facility to a safe and operationally efficient condition.

– Breakdown maintenance: it is performed after the occurrence of an advanced considered failure for which advanced provision has been made in the form of repair method, spares, materials, labour and equipment.

Disadvantages:

1. Its activities are expensive in terms of both direct and indirect cost.

2.Using this type of maintenance, the occurrence of a failure in a component can cause failures in other components in the same equipment, which leads to low production availability.

MAINTENANCE

UNPLANNED

MAINTENANCE

(REACTIVE)

BREAKDOWN

EMERGENCY

PLANNED MAINTENAN

CE (PROACTIVE

)

CORRECTIVE

MAINTENANCE

REMEDIAL

DEFERRED

PREDECTIVE

MAINTENANCE

CONDITION - BASED

STATISTICAL -

BASED

PREVENTIVE

MAINTENANCE

ROUTINE

RUNNING

DESIGN - OUT

ENGINEERING

SERVICES

WINDOW

IMPROVEMENT

MAINTENANCE

SHUTDOWN CORRECTIV

E

SHUTDOWN PREVENTIV

E

SHUTDOWN IMPROVEME

NT

Shutdown Maintenance

OPPORTU-NITY

3. Its activities are very difficult to plan and schedule in advance.

This type of maintenance is useful in the following situations:

1.The failure of a component in a system is unpredictable.

2.The cost of performing run to failure maintenance activities is lower than performing other activities of other types of maintenance.

3.The equipment failure priority is too low in order to include the activities of preventing it within the planned maintenance budget.

2.5.2 Preventive Maintenance (PM)

It is a set of activities that are performed on plant equipment, machinery, and systems before the occurrence of a failure in order to protect them and to prevent or eliminate any degradation in their operating conditions. British Standard 3811:1993 Glossary of terms defined preventive maintenance as:

the maintenance carried out at predetermined intervals or according to prescribed criteria and intended to reduce the probability of failure or the degradation of the functioning and the effects limited.

• The advantage of applying preventive maintenance activities is to satisfy most of maintenance objectives.

• The factors that affect the efficiency of this type of maintenance:

1.The need for an adequate number of staff in the maintenance department in order to perform this type of maintenance.

2.The right choice of production equipment and machinery that is suitable for the working environment and that can tolerate the workload of this environment.

3.The required staff qualifications and skills, which can be gained through training.

4.The support and commitment from executive management to the PM programme.

5.The proper planning and scheduling of PM programme.

6.The ability to properly apply the PM programme.

It is good for those machines and facilities which their failure would cause serious production losses.

Its aim is to maintain machines and facilities in such a condition that breakdowns and emergency repairs are minimised.

Its activities include replacements, adjustments, major overhauls, inspections and lubrications.

Researchers subdivided preventive maintenance into different kinds according to the nature of its activities:

Routine maintenance which includes those maintenance activities that are repetitive and periodic in nature such as lubrication, cleaning, and small adjustment.

Running maintenance which includes those maintenance activities that are carried out while the machine or equipment is running and they represent those activities that are performed before the actual preventive maintenance activities take place.

2.5.3 Preventive Maintenance (PM)

Opportunity maintenance which is a set of maintenance activities that are performed on a machine or a facility when an unplanned opportunity exists during the period of performing planned maintenance activities to other machines or facilities.

Window maintenance which is a set of activities that are carried out when a machine or equipment is not required for a definite period of time.

Shutdown preventive maintenance, which is a set of preventive maintenance activities that are carried out when the production line is in total stoppage situation.

2.5.4 Corrective Maintenance (CM)

In this type, actions such as repair, replacement, or restore will be carried out after the occurrence of a failure in order to eliminate the source of this failure or reduce the frequency of its occurrence.

In the British Standard 3811:1993 Glossary of terms, corrective maintenance is defined as:the maintenance carried out after recognition and intended to put an item into a state in which it can perform a required function.

• This type of maintenance is subdivided into three types:• Remedial maintenance, which is a set of activities that are performed to eliminate the

source of failure without interrupting the continuity of the production process.

The way to carry out this type of corrective maintenance is by taking the item to be corrected out of the production line and replacing it with reconditioned item or transferring its workload to its redundancy.

• Deferred maintenance, which is a set of corrective maintenance activities that are not immediately initiated after the occurrence of a failure but are delayed in such a way that will not affect the production process.

• Shutdown corrective maintenance, which is a set of corrective maintenance activities that are performed when the production line is in total stoppage situation.

• The main objectives of corrective maintenance are the maximisation of the effectiveness of all critical plant systems, the elimination of breakdowns, the elimination of unnecessary repair, and the reduction of the deviations from optimum operating conditions.

• The difference between corrective maintenance and preventive maintenance is that for the corrective maintenance, the failure should occur before any corrective action is taken.

• Corrective maintenance is different from run to failure maintenance in that its activities are planned and regularly taken out to keep plant’s machines and equipment in optimum operating condition.

• The way to perform corrective maintenance activities is by conducting four important steps:

1. Fault detection.2. Fault isolation.3. Fault elimination.4. Verification of fault elimination.

In the fault elimination step several actions could be taken such as adjusting, aligning, calibrating, reworking, removing, replacing or renovation.

• Corrective maintenance has several prerequisites in order to be carried out effectively:1.Accurate identification of incipient problems.2.Effective planning which depends on the skills of the planners, the availability of well

developed maintenance database about standard time to repair, a complete repair procedures, and the required labour skills, specific tools, parts and equipment.

3.Proper repair procedures.4.Adequate time to repair.5.Verification of repair.

2.5.5 Improvement Maintenance (IM)

It aims at reducing or eliminating entirely the need for maintenance. This type of maintenance is subdivided into three types as follows:

1. Design-out maintenance which is a set of activities that are used to eliminate the cause of maintenance, simplify maintenance tasks, or raise machine performance from the maintenance point of view by redesigning those machines and facilities which are vulnerable to frequent occurrence of failure and their long term repair or replacement cost is very expensive.

2. Engineering services which includes construction and construction modification, removal and installation, and rearrangement of facilities.

3. Shutdown improvement maintenance, which is a set of improvement maintenance activities that are performed while the production line is in a complete stoppage situation.

• Predictive maintenance is a set of activities that detect changes in the physical condition of equipment (signs of failure) in order to carry out the appropriate maintenance work for maximising the service life of equipment without increasing the risk of failure.

• It is classified into two kinds according to the methods of detecting the signs of failure: – Condition-based predictive maintenance– Statistical-based predictive maintenance

2.5.6 Predictive Maintenance (PDM)

• Condition-based predictive maintenance depends on continuous or periodic condition monitoring equipment to detect the signs of failure.

• Statistical-based predictive maintenance depends on statistical data from the meticulous recording of the stoppages of the in-plant items and components in order to develop models for predicting failures.

• The drawback of predictive maintenance is that it depends heavily on information and the correct interpretation of the information.

• Some researchers classified predictive maintenance as a type of preventive maintenance.

• The main difference between preventive maintenance and predictive maintenance is that predictive maintenance uses monitoring the condition of machines or equipment to determine the actual mean time to failure whereas preventive maintenance depends on industrial average life statistics.

BAB III

PEMBAHASAN

Dalam praktikum prefentif maintenance, kami melakukan kegiatan bongkar pasang ball screw, eretan dan gearbox eretan pada mesin bubut Schaublin 150 dan pembongkaran spindle mesin bor frais fehlmann. Setelah itu, kami juga melakukan kalibrasi terhadap mesin bor frais fehlmann. Berikut adalah kegiatan yang kami lakukan selama kegiatan preventif maintenance :

3.1 Pembongkaran ball screw

Dalam proses pembongkaran ball screw ini melatih kemampuan maintenance mechanic untuk memahami struktur kerja dari suatu alat dan memahami langkah pembongkaran yang benar. Untuk melakukan kegiatan bongkar pasang, telebih dahulu dilakukan persiapan – persiapan sebagai berikut:1. mempelajari terlebih dahulu manual book mesin yang akan dibongkar2. mempersiapkan tool kit sehingga segala kebutuhan peralatan bisa terpenuhi3. melakukan kegiatan dokumentasi baik berupa foto ataupun gambar sketsa yang

memperlihatkan konstruksi part mesin sebelum dan sesudah dibongkar. Hal ini bertujuan agar kita mempunyai patokan konstruksi part mesin ketika perbaikan atau pengecekan selesai dilakukan

4. melakukan pelabelan terhadap elemen – elemen pengikat part mesin (baut dan mur) yang biasanya sering kali tertukar ketika melakukan bongkar pasang

5. bersikap pro aktif terhadap instruktur ataupun teman praktek ketika ada sesuatu yang tidak diketahui atau diragukan. Belajar dari kesalahan yang pernah dibuat sehingga perbaikkan untuk kedepannya

Dalam hal ini, ball screw memiliki beberapa bagian utama:

ball ( bola gelinding ) berfungsi sebagai elemen putar pada ball screw nut ball screw berfungsi sebagai tempat berputarnya ball rumah ball screw, biasanya terpasang pada eretan mesin, sebgai

tempat ball screw berada. Elemen pengikat ball screw.

Pembongkaran ball screw merupakan kegiatan awal yang dilakukan oleh seluruh mahasiswa maintenance mechanic mengingat kegiatan – kegiatan selanjutnya akan menghadapi berbagai elemen pada mesin yang memiliki tingkat kompleksitas yang lebih tinggi, diharapkan setelah melakukan bongkar pasang ball screw mahasiswa memiliki kepercayaan diri dan kompetensi untuk membongkar bagian mesin lainnya.

Beberapa foto pembongkaran ball screw:

Nut ball screw

Pembongkaran ball screw

3.2 Trouble Repair Mesin Schaublin 150

Baut pengikat eretan atas BU 04 slacken sehingga harus diganti.Analisa : Baut terjadi slacken akibat rusaknya ulir baut, sehingga tidak mengikat mur, disebabkan oleh pengikatan yang telalu kencang dari operator, ataupun akibat beban kejut yang terjadi pada saat proses pemotongan benda kerja dilakukan.

Seperti prosedur sebelumnya, ada 5 langkah yang kami persiapkan sebelum memulai pembongkaran yaitu :1. mempelajari terlebih dahulu manual book mesin yang akan dibongkar2. mempersiapkan tool kit sehingga segala kebutuhan peralatan bisa terpenuhi3. melakukan kegiatan dokumentasi baik berupa foto ataupun gambar sketsa yang

memperlihatkan konstruksi part mesin sebelum dan sesudah dibongkar. Hal ini bertujuan agar kita mempunyai patokan konstruksi part mesin ketika perbaikan atau pengecekan selesai dilakukan

4. melakukan pelabelan terhadap elemen – elemen pengikat part mesin (baut dan mur) yang biasanya sering kali tertukar ketika melakukan bongkar pasang

5. bersikap pro aktif terhadap instruktur ataupun teman praktek ketika ada sesuatu yang tidak diketahui atau diragukan. Belajar dari kesalahan yang pernah dibuat sehingga perbaikkan untuk kedepannya

Setelah baut pengikat eretan atas diganti, baut tidak lagi slacken dan dapat berfungsi sebagaimana mestinya.

3.3 Inspeksi mesin gerinda datar surfemac

Dalam inspeksi kali ini hal yang kami lakukan hanya terbatas pada pengecekan kondisi mesin, pelumasan dan pengecekan kondisi mesin.

Ketika melakuakn pemeriksaan, kami menemukan bahwa kondisi mesin sangat kotor, sehingga membutuhkan pembersihan, terlihat sekali kotoran telah mengeras dan menjadi kerak sehingga sulit untuk di bersihkan. Lagi – lagi kesadaran operator sangat rendah untuk menjaga kondisi kebersihan mesin yang harusnya menjadi tanggung jawab kita bersama.

3.4 Pelumasan mesin Teori pelumasan

Pelumasan khususnya di polman, dibagi kedalam symbol warna dan simbol bentuk. Symbol warna berfungsi untuk membedakan jenis pelumas pada mesin, setiap pelumas memiliki spesifiksi tersendiri seperti :

Tellus C 10 velocity 6 digunakan untuk pelumasan terhadap gearbox special, seperti pada gearbox mesin frais schaublin 53 N. pelumas in juga bisa diganti dengan morlina 10

Tellus 32 digunakan untuk pelumasan terhadap komponen hidrolik, yang umumnya digunakan di mesin gerinda.

Tellus 68 digunakan untuk pelumasan terhadap gearbox standar mesin. Pada umumnya tellus 68 digunakan pada gearbox mesin frais dan bubut di polman.

Tonna 68 digunakan untuk melumasi bagian yang bergesekan satu sama lain, diharapkan setelah di beri pelumas, terjadi lapisan hidrostatis sehingga komponen yang bergesekan tidak cepat mengalami keausan. Biaanya digunakan untuk bagian – bagian slider pada mesin bubut ataupun frais.

Shell vitrea 150 digunakan unutk pelumasan pada mesin sekrap. Pelumas, tidak selamanya berbentuk cair, ada pula yang berbentuk gel atau

pada umumnya di sebut gemuk, dan ada pula yang berbentuk serbuk biasanya disebut dengan graphit.

Pelaksanaan pelumasan.

Dalam pelaksanaan pelumasan, kami melumasi mesin frais schaublin 53N dan juga mesin bubut grazioli.

Hal yang perlu diperhatikan antara lain :

Check indicator pelumas pada mesin, indicator harus menunjukan pada setengah penuh atau lebih, itu merupakan batas aman pelumasan, jika ternyata kurang, maka harus di beri tambahan pelumas.

Dalam memberikan pelumasan, harus menggunakan pelumas yang sesuai supaya tidak terjadi kesalahan yang mengakibatkan mesin mengalamai gejala tidak normal seperti panas yang berlebihan dan sebagainya.

Pengisian pelumas dilakukan secara bertahap dan perlahan, batas pengisian adalah sampai indikatir menunjukan di ¾ penuh.

3.5 Kalibrasi MesinKalibrasi adalah sebuah kegiatan yang bertujuan untuk memeriksa kondisi geometri mesin ataupun part mesin sehingga dapat diketahui masih layak pakai atau tidak.Ada beberapa syarat yang harus diperhatikan bila kita ingin memulai kalibrasi mesin perkakas antara lain :

Harus ada kalibrator. Kalibrator adalah alat yang digunakan untuk mengkalibrasi, kalibrator harus memiliki ketelitian yang lebih presisi dari alat yang akan di kalibrasi. Biasanya kalibrator sangat dijaga kondisinya supaya tetap valid sebagai kalibrator.

Harus memiliki standar yang jelas tentang hal yang akan di kalibrasi, contoh sederhananya adalah dengan memiliki format kalibrasi, sehingga operator

tidak akan bingung bagian mana yang akan di kalibrasi karena telah di tentukan dalam form kalibrasi.

Orang yang akan melakukan kalibrasi harus memiliki kompetensi yang cukup, dapat menggunakan alat ukur dan alat kalibrasi, dapat menggunakan mesin yang akan di kalibrasi.

Mengutamakan kejujuran dalam mengerjakan kalibrasi, menuliskan hasil kalibrasi sesuai dengan hasil kalibrasi yang ada.

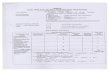

Berikut adalah kegiatan kalibrasiyang kami lakukan pada mesin aciera F4 :

BAB IV

KESIMPULAN dan SARAN

4.1 Kesimpulan

Dari teori dasar dan pembahasan yang telah di bahas di bab sebelumnya, maka bisa

kita tarik kesimpulan bahwa :

Preventive maintenance merupakan kegiatan pemeliharaan yang berfokus kepada

perawatan mesin secara berkala sesuai dengan siklus perawatan mesin yang telah

terjadwal selama 1 tahun.

Ada 5 langkah yang harus di perhatikan ketika akan melakukan pembongkaran mesin

yaitu :

o mempelajari terlebih dahulu manual book mesin yang akan dibongkar

o mempersiapkan tool kit sehingga segala kebutuhan peralatan bisa terpenuhi

o melakukan kegiatan dokumentasi baik berupa foto ataupun gambar sketsa

yang memperlihatkan konstruksi part mesin sebelum dan sesudah dibongkar.

Hal ini bertujuan agar kita mempunyai patokan konstruksi part mesin ketika

perbaikan atau pengecekan selesai dilakukan

o melakukan pelabelan terhadap elemen – elemen pengikat part mesin (baut dan

mur) yang biasanya sering kali tertukar ketika melakukan bongkar pasang

o bersikap pro aktif terhadap instruktur ataupun teman praktek ketika ada

sesuatu yang tidak diketahui atau diragukan. Belajar dari kesalahan yang

pernah dibuat sehingga perbaikkan untuk kedepannya

Pelumasan khususnya di polman, dibagi kedalam symbol warna dan simbol bentuk.

Symbol warna berfungsi untuk membedakan jenis pelumas pada mesin, setiap

pelumas memiliki spesifiksi tersendiri. Pelumasan khususnya di polman, dibagi

kedalam symbol warna dan simbol bentuk. Symbol warna berfungsi untuk

membedakan jenis pelumas pada mesin, setiap pelumas memiliki spesifiksi tersendiri

Kalibrasi adalah sebuah kegiatan yang bertujuan untuk memeriksa kondisi geometri

mesin ataupun part mesin sehingga dapat diketahui masih layak pakai atau tidak.

beberapa syarat yang harus diperhatikan bila kita ingin memulai kalibrasi mesin

perkakas antara lain :

Harus ada kalibrator

Harus memiliki standar yang jelas tentang hal yang akan di kalibrasi

Orang yang akan melakukan kalibrasi harus memiliki kompetensi

Mengutamakan kejujuran dalam mengerjakan kalibrasi

4.2 Saran

Dalam melaksanakan praktek preventive maintenance, kita harus bersikap pro aktif

baik tehadap instruktur maupun teman. Budayakan saling memberi masukan yang

positif demi perbaikan yang berkelanjutan.

Kebersihan dari pengguna mesin/ operator harus lebih di perhatikan, jagan hanya bisa

menggunakan mesin, tetapi tidak bisa merawat dan memelihara mesin supaya mesin

bisa dalam top performancenya. Bagian maintenance bukan membersihkan mesih,

tetapi memelihara, autonomous maintenance sangat kurang, oleh karena itu perlu

ditingkatkan lagi.

Melakukan pelumasan dan kalibrasi dengan hati – hati dan cermat, ingat selalu

langkah – langkah dalam pelaksanaannya sehingga kemungkinan kesalahan yang

terjadi dapat di minimalisasi.

DAFTAR PUSTAKA

http://www.businessdictionary.com/definition/maintenance.html

http://www.merriam-webster.com/dictionary/maintenance http://www.yourdictionary.com/maintenance http://www.thefreedictionary.com/maintenance http://www.sms-anda.com/indonesia/terjemahan/kamus-inggris-atau-

indonesia.php

Related Documents

![Untitled-1 [sim.ihdn.ac.id]sim.ihdn.ac.id/app-assets/repo/repo-dosen-132002102122-34.pdfJudul Makalah Penulis Makalah Identitas Makalah Kategori Publikasi Makalah KARYA ILMIAH : PROSIDING](https://static.cupdf.com/doc/110x72/606da3f0eca44539572e29f4/untitled-1-simihdnacidsimihdnacidapp-assetsreporepo-dosen-132002102122-34pdf.jpg)