INTELLIGENT TOOLING Team 99.08 Joseph Staley Jeffrey Roushey Glenn Gardner Andrew Graybill

INTELLIGENT TOOLING Team 99.08 Joseph StaleyJeffrey Roushey Glenn GardnerAndrew Graybill.

Dec 19, 2015

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

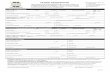

Design Concept Review

• Background - Mission - Approach• Customers - Wants - Constraints• Benchmarking• Quality Metrics - Target Values• Concept Generation• Concept Selection • Schedule - Budget

Project Summary

Mission• To develop a sensor system that will signal the

completion of the metal foaming process inside a mold.

Approach• By working together as a team, making use of

the customer’s resources, and performing extensive research we will provide the best possible sensor system design for our problem.

Customers - Wants - Constraints

Customers Wants Constraints MetricsChin-Jye Yu,FraunhoferUSA

High % ofSuccessfulFoams, SystemSimplicity /Reliability,Low Cost

Cost,OperatingTemperature,LabVIEW,Furnace

Dimensions,Surface Defects,Max. temp, SignalAlts., Set-up time,Mold Alts., Life,Cost, Programtime

Harald Eifert,FraunhoferUSA

High % ofSucessful Foams,Low Cost

Dimensions,Surface Defects,Cost

Customers - Wants - Constraints

Customers Wants Constraints MetricsBernard McGuiness,Lab RA, FRC-DE

Jim Adkins, LabCoordinator, FRC-DE

High % ofSuccessfulFoams, SystemSimplicity /Reliability

OperatingTemperature,Furnace

Dimensions,Surface Defects,Max. temp,Signal Alts., Set-up time, MoldAlts., Life

Automotive,Aerospace, Building/ConstructionIndustries

High % ofSuccessfulFoams, SystemSimplicity /Reliability,Low Cost

OperatingTemperature

Dimensions,Surface Defects,Max. temp,Signal Alts., Set-up time, MoldAlts., Life

System Benchmarking

• Die Casting / Injection Molding– general process, sensors

• High Temperature Monitoring– high temperature materials (Macor)– data acquisition

• Materials Level Monitoring– sensors

Functional Benchmarking

• Electrical Properties Sensors

• Piezo-electric Transducer

• Thermocouple

• Optical Fiber

• Eddy Current Detector

Target Values

Metric Target ValueDimensions 3.5 X 3.5 X 0.5# Surface Defects 0Sensor System Life 5 yearsMaximum Operating Temp. 700 C# Signal Alterations 0Programming Time 20 hoursSet-up Time 30 minutes# Mold Alterations 0Cost $2,000

Critical Functions

• Sense metal foaming process completion

• Attenuate/Amplify the sensor output signal

• Channel signal(s) into data acquisition card

• Use LabVIEW software to interpret signals and alert user that the process is complete

Concept Generation

• Electrical Circuit Completion

• Piezo-Electric Force Sensor

• Thermocouple Array

• Optical Fiber

• Eddy Current Position Sensor

Concept Selection Method

Metric RawScore

SSDCorrelation

WeightedScore

EstimatedTarget Value

Dimensions 4 9.89 39.56 ?# Surface Defects 3 9.89 9.67 No (1)Sensor Sys. Life 5 13.187 65.935 YesMax. Op. Temp. 5 14.286 71.43 Yes# Signal Alts. 5 9.89 49.45 YesProgrmg. Time 5 9.89 49.45 YesSet-up Time 4 9.89 39.56 Yes# Mold Alts. 2 9.89 19.78 No (2)Cost 5 13.187 65.935 Yes

Total Score 430.77

Concept Selection

Concept Total Weighted ScoreElectrical Circuit Completion 431

Piezo-Electric Force Plate 325

Thermocouple Array 312

Eddy Current Position Sensor 235

Optical Fiber 196

Estimated Budget

Part MaterialCost

MachiningCost

ApproximateCost

Copper Mold $5 $495 $500Ceramic Insulator $150 $450 $600Copper Electrode Large $2 $128 $130Copper Electrode Small $2 $128 $130Copper Wire $4 $0 $4Terminal Board $0 $0 $0Battery 9V $0 $0 $0Computer (CPU) $0 $0 $0

Total Cost $1,364

Related Documents