IMB 513 MANUFACTURING SYSTEMS PROJECT ID NO: 201101574 PROJECT ON AUTOMATED PROCESSES- FMS FLEXIBLE MANUFACTURING SYSTEMS Mr Dingalo A Dingalo

Flexible manufacturing systems

Jul 16, 2015

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

IMB 513

MANUFACTURING

SYSTEMS PROJECT

ID NO: 201101574

PROJECT ON

AUTOMATED

PROCESSES-

FMS FLEXIBLE MANUFACTURING

SYSTEMS

Mr Dingalo A Dingalo

TABLE OF CONTENTS

Contents TABLE OF CONTENTS .................................................................................................................... 1

INTRODUCTION ............................................................................................................................ 2

Definition- ................................................................................................................................ 2

AUTOMATED MANUFACTURING CELL ............................................................................................ 3

MANUFACTURING FLEXIBILITY....................................................................................................... 4

EQUIPMENT OF FMS ..................................................................................................................... 5

PRIMARY EQUIPMENT............................................................................................................... 5

SECONDARY EQUIPMENT .......................................................................................................... 6

BASIC COMPONENTS OF A FMS ..................................................................................................... 6

MACHINING STATIONS .............................................................................................................. 7

CNC MACHINING CENTER .......................................................................................................... 7

LOAD/UNLOAD STATIONS ......................................................................................................... 7

MATERIAL HANDLING SYSTEM................................................................................................... 8

OBJETIVES OF FMS........................................................................................................................ 8

TYPES OF FMS-.......................................................................................................................... 9

APPLICATION OF FMS-............................................................................................................... 9

ADVANTAGES OF FMS................................................................................................................. 10

DISADVANTAGES OF FMS ............................................................................................................ 10

REFERENCES ............................................................................................................................... 12

INTRODUCTION

A flexible manufacturing system (FMS) is a group of numerically-controlled machine tools,

interconnected by a central control system. The various machining cells are interconnected,

via loading and unloading stations, by an automated transport system. Operational

flexibility is enhanced by the ability to execute all manufacturing tasks on numerous product

designs in small quantities and with faster delivery. It has been described as an automated

job shop and as a miniature automated factory. Simply stated, it is an automated production

system that produces one or more families of parts in a flexible manner. Today, this

prospect of automation and flexibility presents the possibility of producing nonstandard

parts to create a competitive advantage.

Definition-

“A Flexible Manufacturing System (FMS) is a production system consisting of a set of

identical and/or complementary numerically controlled machine which are connected

through an automated transportation system”.

Each process in FMS is controlled by a dedicated computer (FMS cell computer).

The concept of flexible manufacturing systems evolved during the 1960s when robots,

programmable controllers, and computerized numerical controls brought a controlled

environment to the factory floor in the form of numerically-controlled and direct-

numerically-controlled machines.

For the most part, FMS is limited to firms involved in batch production or job shop

environments. Normally, batch producers have two kinds of equipment from which to

choose: dedicated machinery or automated, general-purpose tools. Dedicated machinery

results in cost savings but lacks flexibility. General purpose machines such as lathes, milling

machines, or drill presses are all costly, and may not reach full capacity. Flexible

manufacturing systems provide the batch manufacturer with another option—one that can

make batch manufacturing just as efficient and productive as mass production.

The first FMS was patent in 1965 by Theo Williamson who made numerically controlled

equipment.

The word “automated” would distinguish this technology from other manufacturing systems

that are flexible but not automated, such as a manned GT machine cell.

The word “flexible” would distinguish it from other manufacturing systems that are highly

automated but not flexible, such as a conventional transfer line.

AUTOMATED MANUFACTURING CELL

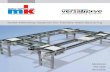

Figure 1: automated manufacturing cell

To qualify as being flexible, a manufacturing system should satisfy several criteria.

Four reasonable TESTS OF FLEXIBILITY:

a) Part variety test. Can the system process different part styles in a non-batch mode? b) Schedule change test. Can the system readily accept changes in production

schedule: changes in either part mix or production quantities?

Machine Work

table

Machine Tool

Parts Carousel

Robot

c) Error recovery test. Can the system recover gracefully from equipment malfunctions and breakdowns, so that production is not completely disrupted?

d) New part test. Can new part designs be introduced into the existing product mix

with relative ease?

MANUFACTURING FLEXIBILITY

Flexibility

type

Definition Dependent on...

Machine flexibility

Capability to adapt a given machine (workstation) in the

system to a wide range of production operations and part styles. The greater the range of operations and part styles, the greater the machine flexibility.

Setup or changeover time. Ease of machine reprogramming

(ease with which part programs can be downloaded to machines).

Tool storage capacity of machines.

Skill and versatility of workers in the system.

Production

flexibility

The range or universe of part

styles that can be produced on

the system.

Machine flexibility of individual

stations.

Range of machine flexibilities of all stations in the system.

Mix flexibility Ability to change the product mix while maintaining the same total production quantity; that is, producing the same parts only in different

proportions.

Similarity of parts in the mix. Relative work content times of

parts produced Machine Flexibility

Product flexibility

Ease with which design changes can be

accommodated. Ease with which new products can be

introduced.

How closely the new part design matches the existing part family.

Off-line part program preparation.

Machine flexibility

Routing flexibility

Capacity to produce parts through alternative station

sequences in response to equipment breakdowns, tool

failures, and other interruptions at individual stations.

Similarity of parts in the mix Similarity of workstations

Duplication of workstations Cross-training of manual workers.

Common tooling.

Volume flexibility

Ability to economically produce parts in high and low total quantities of production, given the fixed investment in the system.

Level of manual labor performing production.

Amount invested in capital equipment.

Expansion flexibility

Ease with which the system can be expanded to increase total production quantities.

Expense of adding workstations. Ease with which layout can be

expanded. Type of part handling system

used. Ease with which properly trained

workers can be added.

EQUIPMENT OF FMS

PRIMARY EQUIPMENT

Work centres

Universal machining centres (prismatic FMSs)

Turning centres (rotational FMSs)

Grinding machines

Nibbling machines

Process centres

Wash machines

Coordinate measuring machines

Robotic work stations

Manual workstations

SECONDARY EQUIPMENT

Support stations

Pallet/fixture load/unload stations

Tool commissioning/setting area

Support equipment

Robots

Pallet/fixture/stillage stores

Pallet buffer stations

Tools stores

Raw material stores

Transport system(AGVs,RGVs,robots)

Transport units(pallets/stillage’s)

BASIC COMPONENTS OF A FMS

Flexible manufacturing systems consist of hardware and software components. The hardware components typically comprise of processing stations, material handling systems and automated material storage and retrieval systems. The processing stations are the workstations that perform different operations on part families. These workstations are CNC machine tools, inspection equipment, assembly stations and material loading/ unloading areas. Material handling systems include automated guided vehicle systems, roller conveyors, tow line, shuttle cars etc. whereas automated storage and retrieval systems are used to store and retrieve work parts automatically. Various types of storage and retrieval systems are pallets, carousels etc. which help in convenient access of different types of parts from stores and increase machine utilization of flexible manufacturing systems. The

processing and assembly equipment used in a flexible manufacturing system depend upon the type of work being accomplished by the system. In a system designed for machining

operations, the principal types of processing stations are CNC machines like CNC machining and turning centers. However, the FMS concept is applicable to various other processes like

automated assembly lines, sheet metal fabrication etc.

MACHINING STATIONS

One of the most common applications of flexible manufacturing system is in the machining

operations. The workstations designed in these systems, therefore, predominantly consist of CNC machines tools. The most common CNC machines tools used include CNC machining

center, in particular, horizontal machining turning centers. These CNC machine tools possess the features that make them compatible with the FMS. These features include automatic

tool changing and storage, use of palletized work parts, etc.

CNC MACHINING CENTER

A CNC machining center is a highly automated machine tool capable of performing multiple machining operations under CNC control in one setup with minimal human attention. Machining centers generally include automated pallet changers to load the work part to the machine and to unload the finished part that can be readily interfaced with the FMS part handling system. A CNC machining center is a sophisticated CNC machine that can perform milling, drilling, tapping, and boring operations at the same location with a variety of tools.

LOAD/UNLOAD STATIONS

Load/unload station is the physical interface between an FMS and the rest of the factory. It

is the place where raw work parts enter the system and finished parts exit the system .Loading and unloading can be accomplished either manually (the most common method) or

by automatic handling systems. The load/unload stations should be ergonomically designed to permit convenient and safe movement of work parts. Mechanized cranes and other

handling devices are installed to assist the operator with the parts that are too heavy to lift by hand. A certain level of cleanliness must be maintained at the workplace, and air houses and other washing facilities are often used to flush away chips and ensure clean mounting and locating points. The station is often raised slightly above the floor level using as open-grid platform to permit chips and cutting fluid to drop through the openings for subsequent recycling or disposal.

The load/unload station includes a data entry unit and a monitor for communication between the operator and the computer system. Through this system, the operator receives

the instructions regarding which part to load on the next pallet in order to adhere to production schedule. When different pallets are required for different parts, the correct

pallet must be supplied to the station. When modular fixing is used, the correct fixture must be specified and the required components and tools must be available at the workstation to

build it. When the part loading procedure is completed, the handling system must launch the pallet into the system, but not until then; the handling system must be prevented from

moving the pallet while the operator is still working. All of these conditions require communication between the computer system and the operator at the load/unload station.

MATERIAL HANDLING SYSTEM

There are two types of material handling systems which are:

Primary handling system establishes the basic layout of the FMS and is responsible

for moving work parts between stations in the system Secondary handling system consists of transfer devices, automatic pallet changing,

and similar mechanisms located at the workstations

Functions of the Handling System

Random, independent movement of work pieces between stations. Handle a variety of work piece configurations.

Temporary storage. Convenient access for loading and unloading work pieces.

Compatible with computer control.

The material-handling equipment used in flexible manufacturing systems include robots, conveyers, automated guided vehicle systems, monorails and other rail guided vehicles, and

other specially designed vehicles. There important features are that they are integrated with the machine centres and the storage and retrieval systems .For prismatic part material

handling systems are accompanied with modular pallet fixtures .For rotational parts industrial robots are used to load/unload the turning machine and to move parts between

stations.

OBJETIVES OF FMS

Stated formally, the general objectives of an FMS are to approach the efficiencies and

economies of scale normally associated with mass production, and to maintain the flexibility

required for small- and medium-lot-size production of a variety of parts.

Two kinds of manufacturing systems fall within the FMS spectrum. These are assembly

systems, which assemble components into final products and forming systems, which

actually form components or final products. A generic FMS is said to consist of the following

components:

1. A set of work stations containing machine tools that do not require significant set-up

time or change-over between successive jobs. Typically, these machines perform

milling, boring, drilling, tapping, reaming, turning, and grooving operations.

2. A material-handling system that is automated and flexible in that it permits jobs to

move between any pair of machines so that any job routing can be followed.

3. A network of supervisory computers and microprocessors that perform some or all

of the following tasks: (a) directs the routing of jobs through the system; (b) tracks

the status of all jobs in progress so it is known where each job is to go next; (c)

passes the instructions for the processing of each operation to each station and

ensures that the right tools are available for the job; and (d) provides essential

monitoring of the correct performance of operations and signals problems requiring

attention.

4. Storage, locally at the work stations, and/or centrally at the system level.

The jobs to be processed by the system. In operating an FMS, the worker enters the job to

be run at the supervisory computer, which then downloads the part programs to the cell

control or NC controller.

TYPES OF FMS-

Sequential FMS

Random FMS

Dedicated FMS

Engineered FMS

Modular FMS

APPLICATION OF FMS-

Metal-cutting machining

Metal forming

Assembly

Joining-welding (arc , spot), gluing

Surface treatment

Inspection

Testing

ADVANTAGES OF FMS The potential benefits from the implementation and utilization of a flexible manufacturing system have been detailed by numerous researchers on the subject. A review of the literature reveals many tangible and intangible benefits that FMS users extol. Thes e benefits include:

achieving a highly automated manufacturing process with rigorous computerized monitoring and management of quality and productivity

making manufacturing operations readily scalable for different levels of output

allowing customization and reconfiguration of manufacturing processes with minimal downtime and cost

providing management with detailed and timely information about the manufacturing process

enabling manufacturers to coordinate their work processes with those of their suppliers and customers to maximize efficiency and minimize costs

Increased machine utilization Fewer machines required

Reduction in factory floor space required Greater responsiveness to change.

Reduced inventory requirements Lower manufacturing lead times

Reduced direct labor requirements and higher labor productivity Opportunity for unattended production

DISADVANTAGES OF FMS

Despite these benefits, FMS does have certain limitations. In particular, this type of system

can only handle a relatively-narrow range of part varieties, so it must be used for similar

parts (family of parts) that require similar processing. Due to increased complexity and cost,

an FMS also requires a longer planning and development period than traditional

manufacturing equipment.

Equipment utilization for the FMS sometimes is not as high as one would expect. Japanese

firms tend to have a much higher equipment utilization rate than U.S. manufacturers

utilizing FMS. This is probably a result of U.S. users' attempt to utilize FMS for high-volume

production of a few parts rather than for a high-variety production of many parts at a low

cost per unit. U.S. firms average ten types of parts per machine, compared to ninety-three

types of parts per machine in Japan.

Other problems can result from a lack of technical literacy, management incompetence, and

poor implementation of the FMS process. If the firm misidentifies its objectives and

manufacturing mission, and does not maintain a manufacturing strategy that is consistent

with the firm's overall strategy, problems are inevitable. It is crucial that a firm's technology

acquisition decisions be consistent with its manufacturing strategy.

If a firm chooses to compete on the basis of flexibility rather than cost or quality, it may be a

candidate for flexible manufacturing, especially if it is suited for low- to mid-volume

production. This is particularly true if the firm is in an industry where products change

rapidly, and the ability to introduce new products may be more important than minimizing

cost. In this scenario, scale is no longer the main concern and size is no longer a barrier to

entry.

However, an FMS may not be appropriate for some firms. Since new technology is costly

and requires several years to install and become productive, it requires a supportive

infrastructure and the allocation of scarce resources for implementation. Frankly, many

firms do not possess the necessary resources. Economically justifying an FMS can be a

difficult task—especially since cost accounting tends to be designed for mass production of

a mature product, with known characteristics, and a stable technology. Therefore, it is

difficult to give an accurate indication of whether flexible manufacturing is justified. The

question remains of how to quantify the benefits of flexibility. In addition, rapidly-changing

technology and shortened product life cycles can cause capital equipment to quickly

become obsolete.

For other firms, their products may not require processes at the technological level of an

FMS. IBM found that a redesigned printer was simple enough for high-quality manual

assembly and that the manual assembly could be achieved at a lower cost than automated

assembly. Potential FMS users should also consider that some of the costs traditionally

incurred in manufacturing may actually be higher in a flexible automated system than in

conventional manufacturing.

REFERENCES 1) J. A. Buzacott,'The Fundamental Principles of Flexibility in Manufacturing Systems',

Proceedings of the 1st International Conference on Flexible Manufacturing Systems.

2) ASKIN R. G., and STANDRIDGE C. R., 1993 “Modelling and Analysis of Manufacturing Syste ms”.

John Wiley and Sons, Inc.

3) Mikell P. Groover, Automation, Production Systems, and Computer-Aided Manufacturing.

Prentice-Hall, Englewood Cliffs NJ (1980).

4) Tauseef Aized (2010). Flexible Manufacturing System: Hardware Requirements, Future

Manufacturing Systems, Tauseef Aized (Ed.), ISBN: 978-953-307-128-2,

5)http://www.intechopen.com/books/future-manufacturing-systems/flexible-manufacturing-

system-hardwarerequirements

Related Documents