Fire Resistive Materials: Adhesion Performance Assessment and Optimization of Fire Resistive Materials NIST July 14, 2005

Fire Resistive Materials: Adhesion Performance Assessment and Optimization of Fire Resistive Materials NIST July 14, 2005.

Dec 16, 2015

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Fire Resistive Materials: Adhesion

Performance Assessment and Optimization of Fire Resistive Materials

NIST

July 14, 2005

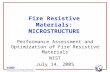

MicrostructureExperimental

3-D Tomography2-D optical, SEM

Confocal microscopy

Modeling3-D Reconstruction

ParametersPorosity

Pore SizesContact Areas

Properties(all as a function of T)

ThermalHeat CapacityConductivity

DensityHeats of Reaction

AdhesionPull-off strength

Peel strengthAdhesion energy

Fracture toughness

EquipmentTGA/DSC/STASlug calorimeter

DilatometerBlister apparatus

Materials Science-Based Studies of Fire Resistive Materials

EnvironmentalInterior

Temperature, RH, load

ExteriorTemperature, RH, UV, load

Performance PredictionLab scale testingASTM E119 Test

Real structures (WTC)

Adhesive Performance of FRMs Why should we care?

• Opportunity: Recent events have demonstrated the importance of in-service adhesive performance in the ability of FRM to protect steel.

•What can we learn about existing adhesive properties of FRM?

How do we measure adhesion?

• Want a geometry independent property. – Adhesive Fracture energy, Gc

How do we measure Gc?

energy to create a unit of surface area units: J/m2

What is Gc

Experimental: Schematic and Theory

4

16

a

wEhG

2

2

1

w

P

EhG

3/43/1

416

1

a

P

EhGP

w

2a

24

1

a

Pw

GAssumptions: Thin, stretching membrane,

loaded elastically and at a point

Eh: Film Tensile Rigidity (modulus, E, · thickness, h)

a

U

bwidth

,

1G

Experimental: Schematic and Theory

4

16

a

wEhG

3/43/1

416

1

a

P

EhG

P

w

2a

Load-based equation (P)

displacement-based equation (w)

Experimental Set-Up:

N kg

Load suspendedfrom center of

specimen

3/43/1

416

1

a

P

EhG

24

1

a

Pw

G

Experimental: Shaft-Loaded Blister Test for WTC Material

2

2

1

w

P

EhG

P

h

Kai Tak Wan and Yiu-Wing Mai,International Journal of Fracture, 74, 181-197 (1995)

E: Young’s Modulus

coating

Rigid substrate

Mechanically drivenshaft attachedto Instron

Shaft attachedTo instron

Stand to hold sample

Film is on the undersideOf stand

Mirror to view film

w

WTC Sample

P

Fire Retardant Material (3/4”)

Primer

2 mil steel

For a bending plate:

2

2

2

w

P

EhG

The mechanical properties of the filmare estimated from:

Steel E (Pa) = 2 * 10^11 h (m) = 0.05 *10^-3

Adhesion PromotorE (Pa) = 3 * 10^9 h (m) = 0.20 *10^-3

and: Ecomposite = v2 E1 +v2 E2

y = 8.7337x - 1.2149

R2 = 0.9965

-0.5

0

0.5

1

1.5

2

2.5

3

3.5

4

0 0.2 0.4 0.6

w (mm)

P (

N)

0

1

2

3

4

5

0 0.2 0.4 0.6 0.8 1

w (mm)

P (

N) 54 % of the

samples were entirely

debonded when received

Experimental: Shaft-Loaded Blister Test

G = 17.3 +/- 12.8 J/m2

Testing of Adhesive Joints:Introduction to Sub-Critical Adhesive Fracture Testing

and the Wedge Test

Wedge Test:

a (t > 0)

a (t = 0)4

32

16

3

ba

EhBG

v-G curves will tell you: -rank order of adhesive -failure mechanisms -engineering design parameters

Log

Cra

ck V

eloc

ity, v

(m/s

)Crack Driving Energy, (J/m )

v(m

/s)

(J/mv

(m/s

)G (J/m 2

10-10

v-G Curve Reveals Mechanisms of Adhesive Failure at the Crack-Tip: Regions I, II, III

v*

Region II: diffusion to crack tip

Region III:stress

controlled

GTh

Region I: stress-dependent chemical reaction

Crack Driving Energy, (J/m )

I

Crack Driving Energy, (J/m )

I

II

Log

Cra

ck V

eloc

ity,

v(m

/s)

Crack Driving Energy, G (J/m2 )

I

III

IncreasingAggressiveness ofEnvironment

Cra

ck V

eloc

ity,

v (

m/s

)

Crack Driving Energy, G (J/m2)

Region II

Application of Sub-Critical Adhesion Testing: Residual Stress (σr) in Coatings

E

vhZ r )1(2

G

σr arise due toCTE mismatch or processing

GThLog

Cra

ck V

eloc

ity, v

(m/s

)Crack Driving Energy, (J/m )

v(m

/s)

(J/mv

(m/s

)G (J/m 2

TE

r

)1(

Data from wedge test

Constant-Load Subcritical Blister Test

4/40” screw

wire

nut and washer(s)

epoxy sealant

wafer substrate

adhesive film

weight

4/40” screw

wire

nut and washer(s)

epoxy sealant

wafer substrate

adhesive film

weight

Constant loadConstant load

3/43/1

416

1

a

P

EhG

ii

ii

tt

aav

1

1*

Measure debond easily with micrometer!

Borofloat®glass substrate

P

1.

Kapton® PSA pre-crack

2. Spin coat PMMA

3. RT cure epoxy adhesive and Kapton® backing

Fire Resistive Coating

Cold Rolled Steel Substrate

1.E-10

1.E-09

1.E-08

1.E-07

1.E-06

1.E-05

1 10 100 1000

debond energy (J/m2)

debo

nd v

eloc

ity

(m/s

)

Epoxy DCB

Screening Tool for Different Coatings Bonded to Cold Rolled Steel at 100% r.h. & RT

A SLBT

B SLBT

A DCB

D

C

1.E-10

1.E-09

1.E-08

1.E-07

1.E-06

1.E-05

1.0 10.0 100.0

debond energy (J/m2)

debo

nd v

eloc

ity

(m/s

)

“Soft” vs. “Hard” Coating, low humidity vs. high humidity

“Hard” coating performs better than “Soft” coating!Coatings perform better at low humidity

High (95%) RH

Low (1%) RH

FRC DCB :

1.E-10

1.E-09

1.E-08

1.E-07

1.E-06

1.0 10.0 100.0 1000.0

debond energy (J/m2)

debo

nd v

eloc

ity

(m/s

)

Increase humidity and reduced residual stress

Tensile Residual Stress is reduced by moisture absorption Reduction in residual stress leads to improved durability

FRM’s.

• Modern Adhesion testing methods can give LRFD parameters.

• These parameters are environmentally sensitive. – (increasing RH can either increase or decrease performance.)

What about Temp and UV? Rate effects?

• What about the existing test methods?– Can we modify existing test methods?

Adhesion Tests: Ideal

• Ideal Adhesion Test:• Simple, cheap, fast, easy to perform

• Grounded in fundamental mechanics and material science- LFRD guidance

– Includes modes- opening, in-plane shear, torsion, mixed,

• Could include environmental and rate dependence.

How far are the test from idea?

Current FRM Standards:

• ASTM E759 (Effect of Deflection)

12 Ft

Deflect 1/120 or 1 inch.

•ASTM E760 (Effect of Impact)

12 Ft

Concrete

60 lb from 4 ft.

•ASTM E736 (Cohesive/Adhesive)

Current Empirical Methods:• Advantages:

– Quick, easy, Cheap

– Practical

– Pass/Fail guidance

• Disadvantages:

– Highly dependent on sample preparation

– Specific to situation tested (geometry, speed, etc)

– Little or no design guidance

Quantitative Adhesive Test Methods: Beam, JKR and Peel Measure G and E

JKR Test

2/12

3 3631

P

WR

P

WR

P

WR

K

PRa

At equilibrium G =W

P

P

a

)465(2

)232(2

8

322422422

22422422

4

32

hthtthBwEEhEwtEB

hthtthBwEEhEwtEB

wa

BEt

aa

aa

G

Beam Test, ex. Wedge Test

Blister Test24

1

a

Pw

G

P

w

2a

PPeel Test(s)

w

PG

Fundamental Mechanics• Advantages:

– Link to fundamental mechanics and material science

properties G– Results are independent of geometry/sample

preparation.

– Gives LFRD guidance

• Disadvantages:– Expensive

– Require equipment

– Time consuming

Current Methods:

• Fundamental Mechanics

– DCLB

– Peel Tests

– Blister Tests

– JKR

• Empirical, Practical– Pull off

– Lap Shear

– Impact

– Deflection

P

P

a

P

w

General Approach:

• Simple Test, – Fast, easy, inexpensive to perform

• Calibrate.– Can be calibrated against fundamental

mechanics and material science– Rate, strain and environmental dependence

• Round robin

Prototype:Steel

FRMBending, twisting, stretching will produce known strains at the interface (different modes)Stress can be calculated from first principles and calibrated with known adhesion geometries.Visually evaluated, or calibrated.Can give both rate and environmental performance.

Never have to touch the material

Summary• Current methods for evaluating the adhesion

performance are pass/fail.• Modern adhesion testing methods present the

ability to give design guidance for FRMs.• It appears possible to build a close to “ideal”

adhesion test for FRMs.– Simple, cheap, fast, based in mechanics, calibrated by

NIST.

Related Documents