Designing a Better Hydroponics System Thomas Ayers Deoveon Craig Alex Veverka

Engineering STEM Hydroponics

Jul 16, 2015

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Designing a Better Hydroponics System

Thomas Ayers

Deoveon Craig

Alex Veverka

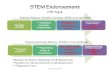

Ask

• Can we build a better hydroponics system ? We are currently using a deep water containment (DWC) unit.

• Can we design a unit that will produce better growth results?

Imagine

Jan. 21, 2014

Imagine

Jan. 21, 2014

Plan

Plan

Jan. 23, 2014

Create

Starting Seedlings Feb. 18, 2014

Safety

March 7, 2013

March 10, 2014

March 13, 2014

Data Collection

Data Analysis

0

1

2

3

4

5

6

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

He

igh

t in

Inch

es

Plant Numbers

Growth Over Time in the PVC Lateral System

26-Feb

19-Mar

0

0.5

1

1.5

2

2.5

3

3.5

DWC Lateral PVC

He

igh

t (i

nch

es)

Hydroponics Units

Comparison of Swiss Chard Seedling Growth inDWC vs. Lateral PVC Hydroponics Units

Improve: Systems Comparison

Improve: “What Can Work Better?”Future Designs & Possible Projects

Conclusion

• We saw better growth in our engineered PVC lateral flow system.

• The PVC unit proved to be a better starter for seedlings. The Swiss chard seedlings were double the size of the seedlings in the DWC unit.

• The strawberry plants ripened quicker in the lateral flow unit.

• Both of these factors, quicker growth and faster ripening of fruit would be important for those who were growing commercially or for personal use.

Reflections

• One of our team’s biggest challenges was finding a type of plant suited to adjust to the environment of the STEM lab, in the dead of winter.

• We started first with sage which we found does not like to be wet.

• Luckily one of our advisors traveled south and brought back lettuce plants and Swiss chard.

Reflections

• Growing plants takes PATIENCE!

• Because plants were scarcely available in December and we began experiencing absences from school during periods of inclement weather, we began planting seeds in case our plants died.

• We also began growing strawberries because of the availability of plants that had been started in a local greenhouse.

Reflections• We had problems with algae growth.

• Algae will compete with plants for nutrients and will decompose leading to waste and bacteria.

Reflections

• Changes we would have made to improve our unit’s efficiencywould be to paint the inside of the PVC pipes in our PVC lateral flow unit black to eliminate some of the algae growth.

Acknowledgements

Related Documents