-

7/24/2019 Dredger 7012hp Dredge

1/6

INNOVATIVE MATERIAL S YSTEMS, A Division of LWT, LLC

THE WORLDS LEADING SUPPLIER OF ONE-TRUCK TRANSPORTABLE SELF-PROPELLED DREDGES

IMS 7012 HPVERSI-DREDG

-

7/24/2019 Dredger 7012hp Dredge

2/6

INNOVATORS

In 1986 Innovative Material Systems (IMS) was born outof the innovative idea that dredging could be madeeasier. Over two decades later and with 500+ dredgesystems in operation in over 45 countries we still takepride as industry innovators. Our modern designsimprove versatility without sacrificing performanceand differentiate us from the rest of the industry.Our innovative approach to customer service andsupport makes sure you are up and running no matter

what corner of the globe you occupy. Our hands onmanagement approach brings our people to you. We arethe innovators of this industry and we are your partner.

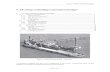

DREDGE EVOLUTION

Evolution is not limited to nature. When designing theVersi-Dredge our engineers listened to the demandsof our global clientele and the marketplace. With eachnew design the Versi-Dredge has evolved into a superiordredging system meeting market demand. The adventof the IMS Model 7012 HP Versi-Dredge marks the zenithof one truck transportable dredge design. As withthe consumer electronics industry, our customers are

demanding more power in a smaller package. Boastinga 445 HP John Deere Turbo Charged power unit, the7012 HP Versi-Dredge is the most powerful one-trucktransportable dredge in the world. In addition, thestandard digging depth of 30 ft. (9.1m) on the 7012 HPVersi-Dredge makes it the deepest digging one trucktransportable dredge in the world. All systems on the7012 HP Versi-Dredge, from the pump, to the cuttersystem, to the propulsion system were painstakinglydesigned and constructed to maximize performancefor the end user. With increased performance levelscomes increased versatility. The 7012 HP Versi-Dredgeis an aggressive dredging system with the power and

durability to work in applications that used to requiredredges two times the size of the 7012 HP. Whether youare restoring a beach in the Caribbean Sea, deepeningthe Tigris River or River Thames, cleaning a tailings pondin a remote region of Africa, or improving access atPenang Port, the Versi-Dredge can handle the jobandalready has. Let us introduce the IMS Model 7012 HPVersi-Dredge, the number one selling standard dredgemodel in the world. Welcome to the evolution.

PATENTED PROPULSION TECHNOLOGY

IMSs patented STARWHEEL Drive self-propulsion systemis a customer-driven patented design that has made

dredging easier by simply eliminating the entire cablerigging process and turning the dredge into a one manwireless operation. Operators no longer need to blockoff entire channels or shut down a marina to cable-rigfor every boat slip. The STARWHEEL Drive system hassimplified the dredging process so much that operatorshave reported production increases of up to 40 percentdue to the fact that the dredge can immediatelymaneuver itself into position without the use of a dredgetender or anchor men, and downtime typically associatedwith repositioning. In addition, the STARWHEEL Drivesystem on the 7012 HP Versi-Dredge is raised andlowered by heavy duty hydraulic rams giving the 7012 HPunmatched bottom surface traction.

In the event that you need to perform surgical dredgingin a grid pattern for an extremely sensitive environmentproject, the 7012HP is equipped with a cable windlasssystem for spooling a traversing cable through the dredgas a secondary form of propulsion. With the addition of Dredging GPS system and an optional IMS EnvironmentaPlus Cutterhead the 7012 HP is now worthy of tackling tmost sensitive environmental projects on the planet.

1

3

5

-

7/24/2019 Dredger 7012hp Dredge

3/6

CUTTING TECHNOLOGY

The Excavator Cutterhead, which comes standard onevery 7012 HP Versi-Dredge, is a unique design that ua combination of replaceable carbide steel pick andshovel teeth to break through consolidated materialsand to convey them to the submersible pump at a higpercentage of solids than other dredge cutterheads. Tcutterhead shroud is green technology that createspowerful vacuum creating a higher solids content whsimultaneously reducing turbidity, unlike conventiona

conical cutterheads which allow the particles to flowunrestricted into the water column. The ExcavatorCutterhead on the 7012 HP Versi-Dredge has up to 10more power than other horizontal type cutter heads the market. The Excavator Cutterhead is powered by high-torque direct drive motors. Since the Versi-Dredcommonly used in applications where large metallic aorganic debris can be found, the system is safe-guardwith a pressure relief valve that will automatically shucutterhead down to prevent damage to the system. TExcavator Cutterhead shroud also comes standard witremovable rock/debris guard that allows the operatorestrict the size of debris that can enter the pump vo

) Peter Bowe, CEO, solidifiescontract for 2 x 7012

Versi-Dredges with the IraqMinistry of Water Resources.

) IMS President, Jim Horton,akes a minute to pose with

DKSH Thailand executives atlive dredge demonstration

utside of Bangkok attendedy over 200 people.

) IMSs multi-million dollarnventory allows buyers to pro-ure equipment immediatelyrom stock.

) IMS Electrical Engineer,Aaron Montgomery, shows alient how to operate the IMS

Model 7012 HP Versi-Dredgemulator at IMSs facility in

New Richmond, WI.

) IMS Global Sales Director,yan Horton, at a remoteredging site in Guatemalas

mountains.

) IMS Territory Manager,Gustavo Marquez, and IMSechnical Sales Manager,

Michael Young, on a dredgete in Colombia.

POWER UNIT Turbo-charged after

cooled 6 cylinder, 445HP John Deere dieselengine

Weather enclosure withlocking doors

OPERATORS

STATION Joystick controlled Electronic depth guage Ergonomic air-ride chair A/C and heating systems Dual bi-folding doors with

port and starboard access Full color discharge line

video monitor

EXCAVATO

CUTTERHE

Dual-recesseddrive motors Replaceable

cutter teeth Shrouded for

turbidity Application v

DREDGE PUMP Ladder-mounted

submersible hydraulicdrive pump

Constructed with GIWspatented Gasite hi-chromewhite iron

Passes up to a 5 inch(127mm) solid

Pumps more solids thanhull mounted pumps

STARWHEEL

DRIVE

SELF-PROPULSION True self-propelled

dredging Eliminates need for cables

or spuds Increases dredge

performance

FLOATATION Compartmentalized

catamaran hull design Steel construction with

bulkhead and skeleton-frame reinforcement

DISCHARGE HOSE 300 ft. (91m) of roll flat

discharge hose and hosefloats included

HYDRAULICS Pumps by Parker & Gold Cup Motors by Parker & Eaton

-

7/24/2019 Dredger 7012hp Dredge

4/6

This feature along with the Excavator Cutterhead flailsystem, which cleans the rock/debris guard after everyrevolution of the cutter, significantly reduces downtimewhen dredging in debris rich environments.

PUMPING TECHNOLOGY

The 7012 HP Versi-Dredge comes standard with a laddermounted GIW 10 in. (254mm) x 12 in. (305mm) LCC-Msubmersible mining grade dredge pump constructed ofGIWs Gasite WD28G hi-chrome white iron. The position

of the pump directly behind the Excavator Cutterheadallows the 7012 HP Versi-Dredge to pump 5%+ moresolids than hull-mounted pump systems thus improvingdewatering rates. The 7012 HP Versi-Dredge pumpsystem can pass up to a 5 in. (127mm) spherical solidand can pump sand a maximum distance of 4,500 ft.(1,372m) depending on the specific gravity of the sandand the concentration. IMS clients report an averagelifespan of the impeller at 4,000+ operating hrs. in fine /

medium grain sands. If your project requires the7012 Hpump beyond 4,500 ft. (1,372m), or even over 20,000 ft(6,098m), then IMS can design a custom pumpingsystem utilizing a series of radio remote-controlledbooster stations.

OPTIONAL D-GPS SYSTEM

The optional IMS D-GPS system allows the operatorto keep track of the dredges position with sub-meteraccuracy. This is ideal for large lakes and rivers where

keeping track of the cuts can be tricky. Additionalsoftware can be added to keep track of where materialhas been removed, a feature which is beneficial forcontract dredging. The IMS Dredging GPS system includa laptop display mounted in the cab, dual GPS receiversand antennas, submersible pressure transducer for augedepth measurement, installation at the factory, andon-site training and calibration.

OPTIONAL BROADCASTING SYSTEM

The optional IMS Broadcaster attachment allows thedredge to quickly discharge the dredged material onshore. This can be highly beneficial when it comes to

dredging an emergency boat channel, wetlands creatioor high-volume dredging in rural canals. The Broadcastefits directly at the discharge end of the dredge ladderin place of the pipeline. The Broadcaster narrows thedischarge diameter of the ladder creating a high-pressucannon that can shoot silt and sand up to 100 feet (30maway from the dredge depending on the percentageof solids.

-

7/24/2019 Dredger 7012hp Dredge

5/6

OPERATING DIMENSIONS

Length 51 ft. 5 in. (15.7 m)

Width 12 ft. (3.66 m)

Height 10 ft. 5 in. (3.2 m) w/air cleaner removed

Weight (less fuel) 47,700 lbs. (21,636 kg)

INTERNATIONAL SHIPPING DIMENSIONS

Length Option 49 ft. 2 in. (15 m) - STARWHEELS removed

Width 12 ft. (3.66 m)

Height 10 ft. (3.1 m) w/ muffler and air filter removed

Weight (less fuel) 46,300 lbs. (21,000 kg)

Shipping Method break bulk service + 20 ocean container

FLOTATION

Dimensions Two (2) pontoons, 45 in. x 43 in. x 468 in.(1,143 mm x 1,092 mm x 11,887 mm); 10 ga.Steel sides, bottom and 1/4 diamond platetops; internal bulkheads and stiffeners.

Displacement 51,562 lbs. (23,388 kg)

Draft 35 in. (889 mm)

WORKING CAPACITY

Cut 135 in. (3,430 mm) wide x 26 in. (660 mm) deep

Working Depth 30 ft. (9.1 m) w/ Starwheel Drive System

Working Depth 32.8 ft. (10.0 m) w/ Cable Drive System

ENGINE

Type John Deere Diesel Model 6135HF485;6 cylinder 13.5 L, 445 HP (332 kW) @ 1,900 rpm

Fuel Capacity 400 gal. (1,516 liters)

Fuel Consumption 22.0 gal./hr. (83.3 lit./hr.)

CUTTERHEAD

Cutterbar Diameter 26 in. (660 mm)

Cutterbar Length 135 in. (3,430 mm)Replaceable Carbide Teeth LEAD: pick / FOLLOW: shovel

Drive Recessed dual hydraulic motor; direct drive withno gear reduction

Speed (variable) 0 to 60 rpm @ 2,500 psi

Cutterhead Torque 23,885 in.-lbs. (2,969 N-m) @ 2,500 psi (peak)

Cutterhead Tip Force 1,837 lbs. (8,171 N)

Cutterhead Rotation Bi-rotational

DREDGE PUMP

Type GIW Cast Iron LCC-M 250-660

Discharge Diameter 10 in. (254 mm)

Suction Diameter 12 in. (304 mm)

Impeller Diameter 26 in. (660 mm)

Sphere Passage 5.0 (127 mm)

Pump Performance 5,000 gpm (315 liter/sec.) @ 125 ft. (38.1 m)TDH (slurry s.g.1.25) @ 760 rpm w/ 2,000 ft.(610 m) discharge length.

Speed (variable) 0 to 760 rpm

Recommended Pipe 12 in. (305 mm), 26 SDR HDPE pipe

PROPULSION

Primary System Patented Starwheel Drive self-propulsion

Secondary System Cable drive system

ELECTRICAL SYSTEM

Voltage 12 volt, negative ground

Alternator Output 130 Amp

SAFETY FEATURES

Includes 2 fire extinguishers, hand rail system, dual folding cabindoors, dual warning horns, 1 life ring, 2 life jackets, lockingpower unit

ANTI-CORROSION FEATURES

Includes Hull below deck is painted with a marine-grade epoxy, abohull deck painted with polyurethane epoxy, and remainingcomponents are coated with heavy duty powder coating asuitable for salt water service. Also includes stainless steelhydraulic lines, fittings, and all suitable hardware.

DECIBEL LEVELS (dB)

Idle (in cab) 66 dB

1,900 rpm (inside cab) 77 dB

2,200 rpm (inside cab) 78 dB

2,200 rpm (@ 25 ft.) 92 dB

2,200 rpm (@ 50 ft.) 85 dB

2,200 rpm (@ 100 ft.) 79 dB

2,200 rpm (@ 200 ft.) 55 dB

HOURLY ESTIMATED OPERATING COSTS ($USD)

Fuel @ $4.00/gallon $88.00

Insurance 2.00

Labor (1 operator @ $16/hr.) 16.00

Labor (1 assistant @ $12/hr.) 12.00

Maintenance (filters, seats, etc.) 1.20

Accrued Mechanical Overhaul 4.00

Pump & Cutterhead Wear 5.00

Hull Maintenance 3.60 ___________

Estimated Hourly Operating Cost $131.80

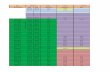

EQUIPMENT STANDARD OPTIONAL

300 ft. (91 m) flexible discharge hose X

12 discharge hose/pipe floats X

Climate Control (A/C & Heat) X

Close-looped discharge line video monitor X

U.S. hand tool kit and tool box X

Rock guard X

Night time operating lights X360 degree spotlight with toggle switch X

Digital depth gauge X

Marine Grade Sound System X

USB Port X

12 in. (305 mm) discharge pipe/hose X

Bi-Directional Broadcaster X

Dredging GPS System X

Cable Drive set-up package X

Dredge navigation lights X

Spare Parts X

Booster Pumps w/ custom instruments X

Environmental Plus Cutterhead X

-

7/24/2019 Dredger 7012hp Dredge

6/6

913-642-5100 or 866-467-4010 (USA Only)

Fax: 913-642-5119

7930 State Line Rd. Ste. # 202

Prairie Village, KS U.S.A. 66208

E-mail: [email protected]

Web Site: www.imsdredge.com