Research Article Decolorization of Distillery Spent Wash Using Biopolymer Synthesized by Pseudomonas aeruginosa Isolated from Tannery Effluent Charles David, 1 M. Arivazhagan, 1 M. N. Balamurali, 2 and Dhivya Shanmugarajan 3 1 Environmental Biotechnology Research Laboratory, Department of Chemical Engineering, National Institute of Technology, Tiruchirappalli, Tamil Nadu 620 015, India 2 Department of Biotechnology, Madha Engineering College, Chennai, Tamil Nadu 600 069, India 3 Biotechnology Division, Asthagiri Herbal Research Foundation, Chennai, Tamil Nadu 600 096, India Correspondence should be addressed to M. Arivazhagan; [email protected] Received 4 June 2015; Accepted 18 August 2015 Academic Editor: Eldon R. Rene Copyright © 2015 Charles David et al. is is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. A bacterial strain was isolated from tannery effluent which can tolerate high concentrations of potassium dichromate up to 1000 ppm. e isolated microorganism was identified as Pseudomonas aeruginosa by performing biochemical tests and molecular characterization. In the presence of excess of carbohydrate source, which is a physiological stress, this strain produces Polyhydroxybutyrate (PHB). is intracellular polymer, which is synthesized, is primarily a product of carbon assimilation and is employed by microorganisms as an energy storage molecule to be metabolized when other common energy sources are limitedly available. Efforts were taken to check whether the PHB has any positive effect on spent wash decolorization. When a combination of PHB and the isolated bacterial culture was added to spent wash, a maximum color removal of 92.77% was found which was comparatively higher than the color removed when the spent wash was treated individually with the PHB and Pseudomonas aeruginosa. PHB behaved as a support material for the bacteria to bind to it and thus develops biofilm, which is one of the natural physiological growth forms of microorganisms. e bacterial growth in the biofilm and the polymer together acted in synergy, adsorbing and coagulating the pollutants in the form of color pigments. 1. Introduction Molasses based distillery effluent contains intense quantities of recalcitrant pollutants in the form of dark colored organic pollutants. e intense color is due to the presence of a dark brown, acidic melanoidin pigment [1]. Melanoidin are a group of polymeric compounds which are a product of the Maillard reaction, a nonenzymatic reaction between sugars and amino compounds [2, 3]. e empirical formula of melanoidin is C 17-18 H 26-27 O 10 N [4]. ese antioxidant and recalcitrant polymers cannot be easily degraded by con- ventional biological treatment methods, namely, anaerobic digestion (biomethanation), anaerobic lagoons, and activated sludge process [5, 6]. When the untreated effluent gets released into surface water resources, the dark coloration of melanoidin hinders the penetration of sunlight into the water, thereby decreasing the photosynthetic activity and eventually affecting the life of aquatic microbiome [7]. Moreover, the high concentrations of chemical oxygen demand (COD), bio- chemical oxygen demand (BOD), and biodegradable organic materials, namely, carbohydrate, lignin, hemicellulose, dex- trins, organic acids, and obnoxious odor [8, 9], were also present in the spent wash effluent. Hence, disposing untreated spent wash effluent into the environment is unsafe to the ecosystem due to high pollution potential [10]. Physicochem- ical treatment methods involve adsorption, coagulation and flocculation, electrocoagulation, advanced oxidation, ozona- tion, membrane filtration, and evaporation. Adsorption and charge neutralization is one of the major physical-chemical treatment methods employed for removing pollutants and color. Hindawi Publishing Corporation BioMed Research International Volume 2015, Article ID 195879, 9 pages http://dx.doi.org/10.1155/2015/195879

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Research ArticleDecolorization of Distillery Spent Wash UsingBiopolymer Synthesized by Pseudomonas aeruginosaIsolated from Tannery Effluent

Charles David1 M Arivazhagan1 M N Balamurali2 and Dhivya Shanmugarajan3

1Environmental Biotechnology Research Laboratory Department of Chemical Engineering National Institute of TechnologyTiruchirappalli Tamil Nadu 620 015 India2Department of Biotechnology Madha Engineering College Chennai Tamil Nadu 600 069 India3Biotechnology Division Asthagiri Herbal Research Foundation Chennai Tamil Nadu 600 096 India

Correspondence should be addressed to M Arivazhagan arivanittedu

Received 4 June 2015 Accepted 18 August 2015

Academic Editor Eldon R Rene

Copyright copy 2015 Charles David et al This is an open access article distributed under the Creative Commons Attribution Licensewhich permits unrestricted use distribution and reproduction in any medium provided the original work is properly cited

A bacterial strain was isolated from tannery effluent which can tolerate high concentrations of potassium dichromate upto 1000 ppm The isolated microorganism was identified as Pseudomonas aeruginosa by performing biochemical tests andmolecular characterization In the presence of excess of carbohydrate source which is a physiological stress this strain producesPolyhydroxybutyrate (PHB) This intracellular polymer which is synthesized is primarily a product of carbon assimilation and isemployed by microorganisms as an energy storage molecule to be metabolized when other common energy sources are limitedlyavailable Efforts were taken to check whether the PHB has any positive effect on spent wash decolorization When a combinationof PHB and the isolated bacterial culture was added to spent wash a maximum color removal of 9277 was found which wascomparatively higher than the color removed when the spent wash was treated individually with the PHB and Pseudomonasaeruginosa PHB behaved as a support material for the bacteria to bind to it and thus develops biofilm which is one of the naturalphysiological growth forms of microorganisms The bacterial growth in the biofilm and the polymer together acted in synergyadsorbing and coagulating the pollutants in the form of color pigments

1 Introduction

Molasses based distillery effluent contains intense quantitiesof recalcitrant pollutants in the form of dark colored organicpollutants The intense color is due to the presence of adark brown acidic melanoidin pigment [1] Melanoidin area group of polymeric compounds which are a product of theMaillard reaction a nonenzymatic reaction between sugarsand amino compounds [2 3] The empirical formula ofmelanoidin is C

17-18H26-27O10N [4] These antioxidant andrecalcitrant polymers cannot be easily degraded by con-ventional biological treatment methods namely anaerobicdigestion (biomethanation) anaerobic lagoons and activatedsludge process [5 6] When the untreated effluent getsreleased into surface water resources the dark coloration ofmelanoidin hinders the penetration of sunlight into thewater

thereby decreasing the photosynthetic activity and eventuallyaffecting the life of aquatic microbiome [7] Moreover thehigh concentrations of chemical oxygen demand (COD) bio-chemical oxygen demand (BOD) and biodegradable organicmaterials namely carbohydrate lignin hemicellulose dex-trins organic acids and obnoxious odor [8 9] were alsopresent in the spentwash effluentHence disposing untreatedspent wash effluent into the environment is unsafe to theecosystem due to high pollution potential [10] Physicochem-ical treatment methods involve adsorption coagulation andflocculation electrocoagulation advanced oxidation ozona-tion membrane filtration and evaporation Adsorption andcharge neutralization is one of the major physical-chemicaltreatment methods employed for removing pollutants andcolor

Hindawi Publishing CorporationBioMed Research InternationalVolume 2015 Article ID 195879 9 pageshttpdxdoiorg1011552015195879

2 BioMed Research International

Biopolymer belongs to the polyesters class which is pro-duced by microorganisms The types of aliphatic polyestersare Polyhydroxyalkanoates (PHA) Polycaprolactone (PCL)and Polylactic acid (PLA) Polyhydroxyalkanoates (PHA) arehydroxyacid polyesters that are synthesized and accumulatedas intracellular granules by a wide variety of bacteria [11]Of the big family of PHAs Polyhydroxybutyrate (PHB) isthe most widespread and well characterized [11] PHB hasaroused much interest in industry and research as a bio-compatible biodegradable thermoplastic and piezoelectricpolymer with potential applications in medical agriculturaland marine fields Generally the production of PHB isenhanced when a suitable carbon source is available inexcess but the cellular growth is limited by another nutrientsuch as nitrogen or phosphorus [11 12] Some bacteria canaccumulate up to 60ndash80 of their weight as PHB [13] Ofthe big family of PHA a homopolymer of 3-hydroxybutyratepoly-3-hydroxybutyrate (PHB) is the most widespread andthe best characterized The polyester PHB is synthesized andaccumulated as intracellular granules by a wide variety ofbacteria It is generally accepted thatmicroorganisms isolatedfrom a natural environment are poor in nutrient sources andthese microorganisms exhibit higher survival abilities thanthose living in the alimentary tract of higher organisms Itis well recognized that this lipid inclusion is accumulated bybacteria as they enter the stationary phase of growth to beused later as an internal reserve of carbon and energy Amongthe factors restricting the economy of PHB production is thecost of the carbon source Hence there arises a lookout for asuitable and inexpensive carbon source for bulk productionof microbial PHB

As PHB is produced from the microorganisms theyare well supported in the development of bacterial biofilmwhich is one of the natural physiological growth forms formicroorganisms over these polymer structures By using thisbiopolymer as support material the biofilm can be enhancedto develop well and it is interesting to use a microbial filmimmobilized on a micro-carrier surface for the productionof a wide variety of biochemicals that can be utilized forother different purposes One of the natural physiologicalgrowth forms for a microorganism is a biofilm in which themicrobial community is attached to a solid surface Fromthe biotechnological point of view it is interesting to use amicrobial film immobilized on a surface as a supportmaterialfor the production of a wide variety of biochemicals that canbe utilized for different purposes [14]

The objective of this study focuses on isolation identifi-cation and characterization of chromium tolerant bacterialstrain from tannery effluent Lab scale production of PHBusing the isolated bacterial strain uses spent wash as the solecarbon source Degradation of organic pollutants in termsof spent wash color uses PHB produced using the isolatedbacterial strain

2 Materials and Methods

21 Collection of Tannery Effluent Sample The tannery efflu-ent sample was collected from Pallavaram Tanners IndustrialEffluent Treatment Co (PTIETC) located near Chromepet

Chennai India This facility treats 3000m3day of tanneryeffluent from the leather processing industrial cluster locatednearby Sample from the activated sludge tank were asepti-cally collected in sterilized glass bottles and transported tothe laboratory and stored in the refrigerator at 4∘C

22 Collection of Distillery Effluent Sample The distilleryeffluent sample was collected from Trichy Distilleries andChemicals Limited (TDCL) located near the city of Tiruchi-rappalli India The collected effluent was immediatelybrought to the laboratory and stored in the refrigerator at 4∘C[15 16] until further use in order to avoid any deterioration inthe physicochemical property of the spent wash

23 Isolation of Metal Tolerant Bacterial Strain from TanneryEffluent The metal tolerant bacterial strain was isolatedby selection pressure method [17] Chromium in the formof potassium dichromate (K

2Cr2O7) was added in varying

concentrations of 10ndash2000 ppm to sterile nutrient agar (pH70) The plates were loaded with 500 120583L of raw effluentand the media was cast by pour-plate method The coloniesdeveloped were counted after 3ndash7 days of incubation at 28∘CIt is possible that some of the organisms die off due topour-plate method Consequently the numbers of Cr (VI)resistant bacterial colonies able to grow were viewed onrelative or comparative basis The increasing concentrationof chromium in the growth medium was given as a stress toresist the growth of the microorganisms The strain capableof growing at maximum concentration was isolated Theisolated bacterial strain was identified with reference toBergeyrsquos Manual of Determinative Bacteriology [18]

24 Molecular Characterization The 24-hour fresh Pseudo-monas sp culture was taken for genomic DNA extractionbased on isolation protocol described by Pitcher et al [19]The extracted DNA sample was run on 1 agarose gelwith 1 k standard marker acquired from Bangalore GeneiPrivate Limited India The universal primers were usedto amplify the 16S rRNA gene region The PCR ampli-fication of 20 120583L reaction mixture containing 1 120583L of thetemplate primers 2120583L of forward primer U3 (51015840AGT-GCCAGCAGCCGCGGTAA31015840) 2 120583L of reverse primer U4(51015840AGGCCCGGGAACGTATTCAC31015840) [20] 12 120583L of assaybuffer 1 120583L of Taq DNA polymerase and 2 120583L of dNTP mixThe amplification was carried out in Thermal Cycler for 35cycles using the following reaction conditions namely initialdenaturation of DNA at 95∘C for 5 minutes denaturation ofDNA at 95∘C for 30 seconds primer annealing at 45∘C for90 seconds and primer extension at 72∘C for 1 minute Theamplified PCR product was mixed with 2120583L of gel loadingbuffer and 1 agarose gel was cast The samples were loadedalong with 2 120583L of 1 kb DNA ladder as a molecular markerThe gel was run and examined on a UV transilluminator tovisualize the bands PCR products were purified by using EZ-10 spin column PCR purification kit and it was sequenced

25 Production of PHB Vincent [21] proposed the com-position of minerals and nutrients to be used in yeastextract mannitol (YEM) broth for the production of PHB

BioMed Research International 3

Acetyl-CoA Acetyl-CoA

Acetoacetyl-CoA

Acetoacetyl-CoAreductase

(R)-3-Hydroxybutyryl-CoA

PHA-synthaseHS-CoA

Polyhydroxybutyrate (PHB)

HS-CoAKetothiolase (PhaA)

NADPH + H+

NADP+

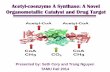

Figure 1 Biosynthetic pathway of Polyhydroxybutyrate (PHB)

The isolated and identified bacterial strain from tanneryeffluent was used for the production of PHB Yeast extractmannitol (YEM) broth (gL) consists of following ingre-dients mannitol 10 g KH

2PO4 05 g MgSO

4sdot7H2O 02 g

NaCl 01 g tryptone 25 g peptone 25 g yeast extract 25 gThe pH of the medium was adjusted to 70 with dilute HClThe batch production of PHB was carried out in 250mLErlenmeyer flasks containing 100mL of culture mediumThetemperature was maintained at 30∘C and the culture wasagitated at 110 rpm The production medium was inoculatedwith a loopful of isolated bacterial culture The biosyntheticpathway of PHB is shown in Figure 1

26Harvesting andAssay of PHB Theisolatedmetal tolerantbacterial strain was cultured in YEM broth at 30∘C for 48hours in an incubator shaker Cultures at stationary phase ofgrowth were centrifuged at 6000timesg for 45min The cell-freesupernatant was discarded The cell pellets were suspendedin 5mL of deionised water and homogenized for 2min ina sonicator bath To 2mL of the cell suspension 2mL of2N HCl was added and boiled for 120min in a water bathThe tubes were centrifuged at 6000timesg for 20min To obtainprecipitate 5mL of chloroform was added The test tubescontaining the suspension were left overnight at 28∘C ona shaker at 150 rpm The contents of the test tubes werecentrifuged at 6000timesg for 20 minutes and 01mL of chloro-form extract was dried at 50∘C About 5mL of concentratedsulfuric acid was added and heated at 100∘C in water bathfor 20min After cooling to room temperature the amountof PHB was determined using UV-Vis spectrophotometer ata corresponding wavelength of 235 nm The schematic step-wise procedure for PHB harvesting is shown in Figure 2

27 Determination of Dry Cell Weight The total dry weight(total biomass) was determined by harvesting washingdrying to constant volume and weighing The non-PHB dry

Polyhydroxybutyrate (PHB)

(30∘C 48 hours)

Centrifuged at for 45 minutes

Centrifuged at for 20 minutes

Centrifuged at for 20 minutes

Cell pellets suspended in 5mLdeionised water sonicated for 2min

Incubated with 2N HCl for 2 hours

5mL chloroform was added for precipitation

Incubated at 28∘C 150 rpm 12h

5mL conc sulfuric acid was addedand heated at 100∘C for 20min

50∘CChloroform extract dried at

Growth in renewable carbon source

6000timesg

6000timesg

6000timesg

Figure 2 Schematic flow diagram representing harvesting andpurification of PHB

weight (non-PHB biomass) was calculated from the total dryweight and the PHB content using the following equation

Non-PHB dry weight = total dry weight

times(100 minusPHB)100

(1)

28 Effect of Different Carbon Sources on PHB ProductionTheusage ofmannitol in YEMmediumbrothwas replaced by

4 BioMed Research International

Figure 3 Microbial colony developed at 1000 ppm of K2Cr2O7dosage concentration

other carbon sources such as glucose fructose dextrose andsucrose in the growth medium Peptone and tryptone werekept as constant nitrogen sources Based on the well-knownfact that molasses is rich in carbon source and inexpensivetrials were performed in which the expensive carbon sourcehas been replaced by inexpensivemolassesThe PHB yield fordifferent carbon sources and molasses was determined

29 Spent Wash Decolorization Studies The batch colorremoval experiments were performed in Erlenmeyer flasks(250mL volume) containing 100mL of raw spent wash Anappropriate dosage of as-synthesized PHB and 48-hour-oldbacterial culture was added as listed below

(1) 2mL of Pseudomonas aeruginosa culture(2) 2mL of PHB synthesized using the isolated strain(3) 2mL (1 1 ratio) of PHB and Pseudomonas aeruginosa

culture

The batch vessels were shifted to an incubator shaker andthe flasks were mildly shaken at 50 rpm Color reduction wasmonitored for 120 h Aliquots of samples were withdrawn andcentrifuged at 10000timesg for 10min to remove the suspendedparticles Color removal was measured at a characteristicwavelength of 475 nm using UV-Visible spectrophotometer(Spectroquant Pharo 300 Merck)

The color removal efficiency was calculated by

Color removed () =1198620minus 119862119905

1198620

times 100 (2)

where 1198620and 119862

119905are the initial absorbance and absorbance at

time 119905 for spent wash effluent at a characteristic wavelengthof 475 nm [22 23]

3 Results and Discussion

31 Isolation of Metal Tolerant Strain By selection pressuremethod the most tolerant bacterial strain was isolated from

tannery effluentThis strainwas found to tolerate amaximumconcentration of 1000 ppm (1000 120583gmL) of K

2Cr2O7 when

cultured in nutrient agar media containing K2Cr2O7as

shown in Figure 3 This method is to enhance the selectionpressure thereby reducing the number of surviving speciesand only to obtain the organism that can withstand suchhigh concentration (1000 ppm) of K

2Cr2O7 At lower concen-

trations numerous well developed colonies were visualizedBut at 1000 ppm of concentration only very few numbersof colonies were formed These highly tolerant colonieswere subcultured and preserved for identification molecularcharacterization of the strain and production of secondarymetabolite

32 Identification of Isolated Bacterial Strain The microor-ganism isolated by the selection pressure method was identi-fied by performing morphological microbial and biochemi-cal tests and the results were compared with Bergeyrsquos Manualof Determinative Bacteriology The colonies formed by theisolated strain were irregular circular in shape with flatcolony elevation with uneven or rough colony margin anddull white to mild beige in color The microorganisms wereidentified to be Gram-negative motile rods as shown inFigure 4 The strain isolated tested positive in catalase testdue to the rapid evolution of gas bubbles when a drop ofH2O2was placed on the bacterial colony showing that there

was an evolution of oxygen and the strain is aerobic Whensubjected to oxidase test the result was positive This is dueto the formation of dark blue purple colorwhich indicates thepresence of cytochrome c oxidase Indole test gave a negativeresult as there was no formation of the cherry red coloredringwhenKovacrsquos reagentwas added to the incubated culturePhenol red test result was negative as the isolated straincannot ferment any of the sugars like glucose sucrose orlactose So there was neither a change in color nor formationand collection of gas inside the inverted Durhamrsquos tubesThe result was methyl red negative upon performing methylred test as there was no red color formation upon additionof methyl red indicator which denotes the fact that the pH

BioMed Research International 5

remains above 60 Formation of colorless colonies was seenwhen they were grown on EMB and MacConkey agar platesThis is due to the reason that the organism cannot fermentlactose sugars The biochemical tests and the correspondingresults are tabulated in Table 1

33 Molecular Characterization The PCR sequenced prod-uct was identified using Bioinformatics tool BLAST andPseudomonas aeruginosa gene for 16S rRNA partial sequencewith 98 query coverage and 99 identity with expectedvalue of zero was found This confirmed that the organismis Pseudomonas aeruginosa The sequence is given as followsand the BLAST results are shown in Figure 5

GCAGGCCTAACACATGCAAGTCGAGCGGAT-GAAGGGAGCTTGCTCCTGGATTCAGCGGCGGAC-GGGTGAGTAATGCCTAGGAATCTGCCTGGTAGT-GGGGGATAACGTCCGGAAACGGGCGCTAATACC-GCATACGTCCTGAGGGAGAAAGTGGGGGATCTT-CGGACCTCACGCTATCAGATGAGCCTAGGTCGG-ATTAGCTAGTTGGTGGGGTAAAGGCCTACCAAG-GCGACGATCCGTAACTGGTCTGAGAGGATGATC-AGTCACACTGGAACTGAGACACGGTCCAGACTC-CTACGGGAGGCAGCAGTGGGGAATATTGGACAA-TGGGCGAAAGCCTGATCCAGCCATGCCGCGTGT-GTGAAGAAGGTCTTCGGATTGTAAAGCACTTTA-AGTTGGGAGGAAGGGCAGTAAGTTAATACCTTG-CTGTTTTGACGTTACCAACAGAATAAGCACCGG-CTAACTTCGTGCCAGCAGCCGCGGTAATACGAA-GGGTGCAAGCGTTAATCGGAATTACTGGGCGTA-AAGCGCGCGTAGGTGGTTCAGCAAGTTGGATGT-GAAATCCCCGGGCTCAACCTGGGAACTGCATCC-AAAACTACTGAGCTAGAGTACGGTAGAGGGTGG-TGGAATTTCCTGTGTAGCGGTGAAATGCGTAGA-TATAGGAAGGAACACCAGTGGCGAAGGCGACCA-CCTGGACTGATACTGACACTGAGGTGCGAAAGC-GTGGGGAGCAAACAGGATTAGATACCCTGGTAG-TCCACGCCGTAAACGATGTCGACTAGCCGTTGG-GATCCTTGAGATCTTAGTGGCGCAGCTAACGCG-ATAAGTCGACCGCCTGGGGAGTACGGCCGCAAG-GTTAAAACTCAAATGAATTGACGGGGGCCCGCA-CAAGCGGTGGAGCATGTGGTTTAATTCGAAGCA-ACGCGAAGAACCTTACCTGGCCTTGACATGCTG-AGAACTTTCCAGAGATGGATTGGTGCCTTCGGG-AACTCAGACACAGGTGCTGCATGGCTGTCGTCA-GCTCGTGTCGTGAGATGTTGGGTTAAGTCCCGT-AACGAGCGCAACCCTTGTCCTTAGTTACCAGCA-CCTCGGGTGGGCACTCTAAGGAGACTGCCGGTG-ACAAACCGGAGGAAGGTGGGGATGACGTCAAGT-CATCATGGCCCTTACGGCCAGGGCTACACACGT-GCTACAATGGTCGGTACAAAGGGTTGCCAAGCC-GCGAGGTGGAGCTAATCCCATAAAACCGATCGT-AGTCCGGATCGCAGTCTGCAACTCGACTGCGTG-AAGTCGGAATCGCTAGTAATCGTGAATCAGAAT-GTCACGGTGAATACGTTCCCGGGCCTTGTACAC-ACCGCCCGTCACACCATGGGAGTGGGTTGCTCC-AGAAGTAGCTAGTCTAACCGCAAGGGGGACGGT-TACCACGGAGTGATTCATGACTGGGGTGAAGTC-GTAACAAGGTA

Figure 4 Gramrsquos staining showing Gram-negative rods of isolatedPseudomonas aeruginosa

34 Production of Polyhydroxybutyrate (PHB) by Using theIsolated Bacterial Strain Pseudomonas aeruginosa Gram-negative motile rod shaped bacteria were able to synthesizePolyhydroxybutyrate (PHB) as an intracellular secondarymetabolite which is a resultant product due to the physiolog-ical stress occurring due to the availability of excess amountof carbon source and limited availability of other mineralsespecially phosphate or nitrogen It has been suggested thatammonia limited cultures of Pseudomonas aeruginosa wereunable to regulate fully the rate at which they take up glucoseparticularly when growing at the low availability of mineralsAs a result they form copious amounts of exopolysaccharideboth to overcome the potentially deleterious osmotic effectsof accumulating surplus intracellular metabolites and to con-sume some of the surplus ATP generated by the oxidation ofthese metabolites [24ndash26] However unlike exopolysaccha-ride PHB is an intracellular product and therefore addition-ally provides a means of storing excess carbon and reducingpower for future use [27] In this context it is interestingto note that Pseudomonas aeruginosa can synthesize PHBor other Polyhydroxyalkanoates exopolysaccharide andorvarious organic acids as alternative products after losing itsability to make exopolysaccharide or PHB respectively byfollowing natural strain degeneration ormutagenesis [25 28]

35 Effect of Different Carbon Sources on PHB ProductionTheyield of PHBbased on various carbon sourceswas studiedand the values along with standard deviation is tabulatedin Table 2 When the carbon source mannitol in the YEMmedium was replaced by molasses a maximum yield of 70PHB was obtained This research finding was a success as themolasses were used and the cost due to the use of mannitolcan also be avoided This is an economical initiative of usingmolasses as a source of carbon in the growth medium ofPseudomonas aeruginosa

The Dunnettrsquos multiple comparison test was used to findthe statistical significance of the various carbon sources incomparison with the control (YEM) In Table 3 the values

6 BioMed Research International

Color key for alignment scores

Query

1 250 500 750 1000 1250

NR_074828 Pseudomonas aeruginosa PAO 1 strain PAO1 16S ribosomal = 2697 E = 0

lt40 ge20040ndash50 50ndash80 80ndash200

SR

Figure 5 BLAST results for the isolated bacterial strain Pseudomonas aeruginosa

Table 1 Biochemical and morphological characterization of isolated bacterial strain

Biochemical test Result Morphology ResultGram staining minus Colony shape Irregular roundCatalase test + Colony elevation FlatOxidase test + Colony size (mm) 25Indole test minus Colony margin SerratedPhenol red test minus Colony color Dull whiteMethyl red test minus Motility MotileGrowth on EMB agar minus Cell shape RodGrowth on MacConkey agar minus

Table 2 Effect of various carbon sources on PHB production with standard deviation values

Carbon source Dry cell weight (gL) SD Amount of PHB (gL) SD PHB yield () SDGlucose 022 0007 0026 00007 1182 0049Sucrose 023 001 0049 00008 2130 0141Fructose 132 00282 0072 00021 545 0219Molasses 021 00131 0147 00014 700 0707Control (YEM) 028 00141 0060 00135 2143 00636SD standard deviation

Table 3 Effect of various carbon sources on PHB production with standard deviation values

Dunnettrsquos multiple comparison test Significant Summary Adjusted 119901 valueDry cell weight

Control (YEM) versus glucose Yes lowast 00178Control (YEM) versus sucrose No ns 00683Control (YEM) versus fructose Yes lowastlowastlowastlowast lt00001Control (YEM) versus molasses Yes lowast 00235

Amount of PHBControl (YEM) versus glucose Yes lowastlowast 00029Control (YEM) versus sucrose No ns 00682Control (YEM) versus fructose No ns 09459Control (YEM) versus molasses Yes lowastlowastlowast 00002

yield of PHBControl (YEM) versus glucose Yes lowastlowastlowastlowast lt00001Control (YEM) versus sucrose No ns gt09999Control (YEM) versus fructose Yes lowastlowastlowastlowast lt00001Control (YEM) versus molasses Yes lowastlowastlowastlowast lt00001ns not significant

BioMed Research International 7

with 119901 lt 005 are considered significant with symbol lowastindicating mild significance and symbol lowast lowast lowastlowast indicatingmore significance in comparison with the control medium

36 Effect of Time on PHBProduction It was found that whenmolasses were used as the carbon source in YEM mediuminstead of mannitol at the end of 48 hours the PHB yieldwas 70 After 48 hours of incubation there was a decreasein the PHB yield and increase in the viscosity of the mediumThe increase in the viscosity of the growth medium resultedin a limited oxygen transfer rate and caused the fall of PHBsynthesis and accumulation inside the bacterial cells ThePHB yield decreased to 32 after 72 hours of incubation and18 after 120 hours of incubation Even the dry cell weightwas increased up to 120 hours The decrease in the PHBcontent explained that the bacteria have used the producedPHB as a source of carbon to survive due to the unavailabilityof the carbon sourceThePHByield alongwith the standarddeviation values has been plotted as shown in Figure 6

37 Spent Wash Decolorization Study This initiative of test-ing the effect of the isolated bacterial culture and the as-synthesized PHB on spent wash decolorization was per-formed as a trial and very positive and welcoming resultswere obtained as shown in Figure 7 At the end of five-daybatch study a combination consisting of 2mL (1 1 ratio) ofPHB and Pseudomonas aeruginosa culture was able to achieve9277 spent wash color removal whereas there was onlya minimal color reduction (2530 and 1358) resultingwhen the spent wash was treated with microorganism andPHB individuallyThe increased color removal was due to thephenomenon that the Gram-negative bacteria Pseudomonasaeruginosa possess negative surface charge When thesebacterial cultures were added to the effluent along withthe PHB the bacteria bind to the PHB hence forminga biofilm and thereby also act as an ion exchange thatattracts the suspended organic particles to get bound to thebiofilm This biofilm acts as a support material and favors asuitable condition for the further growth and developmentof the bacteria Thus the synergic actions of the PHB andthe microorganism were found to be the most capable ofperforming spent wash decolorization

38 Research Outcome The positive results of this researchcould lead to a more advanced technique and applicationwhere the microbially produced PHB can be used as ananobiomaterial possessing tunable propertieswith a focusedapplication for binding and removal of heavy metals fromaqueous industrial effluents As the synthesis of biopolymerrelies on a principle of single phase transition scaling up theproduction process could be of a less intensive task henceproviding an ecofriendly technology for pollutant removal

4 Conclusion

In this research paper bacterial strain possessing tolerance tohigh concentrations of chromium was isolated from tanneryeffluent The isolated strain was identified as Pseudomonasaeruginosa by biochemical and molecular characterization

Dry cell weight

Amount of PHB

Control (YEM)

Control (YEM)

Glucose

Glucose

SucroseCarbon sources

Sucrose

Fructose

Fructose

Molasses

Molasses

Control (YEM)

Control (YEM)

Glucose

Glucose

SucroseCarbon sources

PHB80

60

40

20

0

Yiel

d (

)

Sucrose

Fructose

Fructose

Molasses

Molasses

Control (YEM)

Control (YEM)

Glucose

Glucose

SucroseCarbon sources

Sucrose

Fructose

Fructose

Molasses

Molasses

(gL

)

00

000

005

010

(gL

)

015

020

05

10

15

Figure 6 Bar charts with standard deviation values for dry cellweight amount of PHB and yield of PHB

8 BioMed Research International

PseudomonasPHBPseudomonas + PHB

Time (h)0

010

10

20

20

30

30

40

40

50

50

60

60

70

70

80

80

90

100

Col

or re

mov

ed (

)

90

Figure 7 Effect of time on color removal by microbial culturePHB and combination of microbial culture and PHB

Efforts were taken to synthesize Polyhydroxybutyrate (PHB)using the isolated bacterial strain Mannitol an expensivecarbon source for the bacterial growth culture media wasreplaced with inexpensive molasses The exopolysaccharidesaccumulated by the bacterial cells were harvested and sep-arated Optimization of suitable quantities of as-synthesizedPHB and microbial culture was tested to evaluate the colorremoval efficiency The results showed that Pseudomonasaeruginosa exhibited a synergistic effect in combination (1 1ratio) with the biopolymer towards spent wash decoloriza-tion Lab scale optimization experiments resulted in 9277removal of spent wash color after 96 hours of treatmentwhereas there was only a limited color reduction (2530 and1358) observed when the same concentration and volumeof spent wash was treated with Pseudomonas aeruginosaculture and PHB individually

Conflict of Interests

The authors report no conflict of interests

Acknowledgments

Charles David is supported by the Technical EducationQuality Improvement Program (TEQIP) Phase II a WorldBank initiative The authors thank TEQIPminusII and NationalInstitute of Technology Tiruchirappalli Tamil Nadu India

References

[1] E C Bernardo R Egashira and J Kawasaki ldquoDecolorizationof molassesrsquo wastewater using activated carbon prepared fromcane bagasserdquo Carbon vol 35 no 9 pp 1217ndash1221 1997

[2] V P Migo M Matsumura E J Del Rosario and H KataokaldquoDecolorization of molasses wastewater using an inorganic

flocculantrdquo Journal of Fermentation and Bioengineering vol 75no 6 pp 438ndash442 1993

[3] N Naik K S Jagadeesh and M N Noolvi ldquoEnhanced degra-dation of melanoidin and caramel in biomethaneted distilleryspent wash by micro-organisms isolated from mangrovesrdquoIranica Journal of Energy and Environment vol 1 pp 347ndash3512010

[4] P Manisankar C Rani and S Viswanathan ldquoEffect of halidesin the electrochemical treatment of distillery effluentrdquo Chemo-sphere vol 57 no 8 pp 961ndash966 2004

[5] Y Satyawali and M Balakrishnan ldquoRemoval of color frombiomethanated distillery spentwash by treatment with activatedcarbonsrdquo Bioresource Technology vol 98 no 14 pp 2629ndash26352007

[6] Y Zhou Z Liang and Y Wang ldquoDecolourization and CODremoval of secondary yeast wastewater effluents by coagulationusing aluminum sulphatrdquo Desalination vol 225 no 1ndash3 pp301ndash311 2008

[7] R K Prasad ldquoColor removal fromdistillery spent wash throughcoagulation using Moringa oleifera seeds use of optimumresponse surfacemethodologyrdquo Journal of HazardousMaterialsvol 165 no 1ndash3 pp 804ndash811 2009

[8] G S Kumar S K Gupta and S Gurdeep ldquoAnaerobic hybridreactormdasha promising technology for the treatment of distilleryspent washrdquo Journal of Indian School of Mines vol 11 pp 25ndash382007

[9] S Venkata Mohan G Mohanakrishna S V Ramanaiah and PN Sarma ldquoSimultaneous biohydrogen production and wastew-ater treatment in biofilm configured anaerobic periodic discon-tinuous batch reactor using distillery wastewaterrdquo InternationalJournal of Hydrogen Energy vol 33 no 2 pp 550ndash558 2008

[10] S Mohana B K Acharya and D Madamwar ldquoDistilleryspent wash treatment technologies and potential applicationsrdquoJournal of Hazardous Materials vol 163 no 1 pp 12ndash25 2009

[11] S Y Lee ldquoBacterial polyhydroxyalkanoatesrdquo Biotechnology andBioengineering vol 49 no 1 pp 1ndash14 1996

[12] J Choi and S Y Lee ldquoFactors affecting the economics ofpolyhydroxyalkanoate production by bacterial fermentationrdquoApplied Microbiology and Biotechnology vol 51 no 1 pp 13ndash211999

[13] A J Anderson and E A Dawes ldquoOccurrence metabolismmetabolic role and industrial uses of bacterial polyhydrox-yalkanoatesrdquo Microbiological Reviews vol 54 no 4 pp 450ndash472 1990

[14] J Varani M Dame T F Beals and J A Wass ldquoGrowth of threeestablished cell lines on glass microcarriersrdquo Biotechnology andBioengineering vol 25 no 5 pp 1359ndash1372 1981

[15] Y Yavuz ldquoEC and EF processes for the treatment of alcoholdistillery wastewaterrdquo Separation and Purification Technologyvol 53 no 1 pp 135ndash140 2007

[16] C David R Narlawar andMArivazhagan ldquoPerformance eval-uation of Moringa oleifera seed extract (MOSE) in conjunctionwith chemical coagulants for treating distillery spent washrdquoIndian Chemical Engineer vol 1 pp 1ndash12 2015

[17] I Ghanem M Orfi and M Shamma ldquoBiodegradation ofchlorphyrifos by Klebsiella sp isolated from an activated sludgesample of waste water treatment plant in damascusrdquo FoliaMicrobiologica vol 52 no 4 pp 423ndash427 2007

[18] Bergeyrsquos Manual of Systematic Bacteriology Springer 2nd edi-tion 1985

BioMed Research International 9

[19] D G Pitcher N A Saunders and R J Owen ldquoRapid extractionof bacterial genomic DNAwith guanidium thiocyanaterdquo Lettersin Applied Microbiology vol 8 no 4 pp 151ndash156 1989

[20] G James ldquoUniversal bacterial identification by PCR and DNAsequencing of 16S rRNA generdquo in PCR for Clinical MicrobiologyM Schuller T P Sloots G S James C L Halliday and I WJ Carter Eds pp 209ndash214 Springer Science+Business MediaAmsterdam The Netherlands 2010

[21] J M Vincent ldquoA manual for the practical study of the root-nodule bacteriardquo in IBP Handbook 15 Blackwell ScientificPublishers Oxford UK 1970

[22] C David M Arivazhagan and F Tuvakara ldquoDecolorization ofdistillery spent wash effluent by electro oxidation (EC and EF)and Fenton processes a comparative studyrdquo Ecotoxicology andEnvironmental Safety 2015

[23] C Raghukumar and G Rivonkar ldquoDecolorization of molassesspent wash by the white-rot fungus Flavodon flavus isolatedfrom amarine habitatrdquoAppliedMicrobiology and Biotechnologyvol 55 no 4 pp 510ndash514 2001

[24] A Cornish J A Greenwood and CW Jones ldquoThe relationshipbetween glucose transport and the production of succinoglucanexopolysaccharide by Agrobacterium radiobacterrdquo Journal ofGeneral Microbiology vol 134 pp 3111ndash3122 1988

[25] S GWilliams J A Greenwood andCW Jones ldquoPhysiologicaland biochemical changes accompanying the loss of mucoidy byPseudomonas aeruginosardquoMicrobiology vol 142 no 4 pp 881ndash888 1996

[26] A J Rye J W Drozd C W Jones and J D Linton ldquoGrowthefficiency of Xanthomonas campestris in continuous culturerdquoMicrobiology vol 134 no 4 pp 1055ndash1061 1988

[27] P J Senior G A Beech G A Ritchie and E A DawesldquoThe role of oxygen limitation in the formation of poly-120573-hydroxybutyrate during batch and continuous culture ofAzotobacter beijerinckiirdquo Biochemical Journal vol 128 no 5 pp1193ndash1201 1972

[28] U Breuer J-U Ackermann and W Babel ldquoAccumula-tion of poly(3-hydroxybutyric acid) and overproduction ofexopolysaccharides in amutant of amethylotrophic bacteriumrdquoCanadian Journal of Microbiology vol 41 no 1 pp 55ndash59 1995

2 BioMed Research International

Biopolymer belongs to the polyesters class which is pro-duced by microorganisms The types of aliphatic polyestersare Polyhydroxyalkanoates (PHA) Polycaprolactone (PCL)and Polylactic acid (PLA) Polyhydroxyalkanoates (PHA) arehydroxyacid polyesters that are synthesized and accumulatedas intracellular granules by a wide variety of bacteria [11]Of the big family of PHAs Polyhydroxybutyrate (PHB) isthe most widespread and well characterized [11] PHB hasaroused much interest in industry and research as a bio-compatible biodegradable thermoplastic and piezoelectricpolymer with potential applications in medical agriculturaland marine fields Generally the production of PHB isenhanced when a suitable carbon source is available inexcess but the cellular growth is limited by another nutrientsuch as nitrogen or phosphorus [11 12] Some bacteria canaccumulate up to 60ndash80 of their weight as PHB [13] Ofthe big family of PHA a homopolymer of 3-hydroxybutyratepoly-3-hydroxybutyrate (PHB) is the most widespread andthe best characterized The polyester PHB is synthesized andaccumulated as intracellular granules by a wide variety ofbacteria It is generally accepted thatmicroorganisms isolatedfrom a natural environment are poor in nutrient sources andthese microorganisms exhibit higher survival abilities thanthose living in the alimentary tract of higher organisms Itis well recognized that this lipid inclusion is accumulated bybacteria as they enter the stationary phase of growth to beused later as an internal reserve of carbon and energy Amongthe factors restricting the economy of PHB production is thecost of the carbon source Hence there arises a lookout for asuitable and inexpensive carbon source for bulk productionof microbial PHB

As PHB is produced from the microorganisms theyare well supported in the development of bacterial biofilmwhich is one of the natural physiological growth forms formicroorganisms over these polymer structures By using thisbiopolymer as support material the biofilm can be enhancedto develop well and it is interesting to use a microbial filmimmobilized on a micro-carrier surface for the productionof a wide variety of biochemicals that can be utilized forother different purposes One of the natural physiologicalgrowth forms for a microorganism is a biofilm in which themicrobial community is attached to a solid surface Fromthe biotechnological point of view it is interesting to use amicrobial film immobilized on a surface as a supportmaterialfor the production of a wide variety of biochemicals that canbe utilized for different purposes [14]

The objective of this study focuses on isolation identifi-cation and characterization of chromium tolerant bacterialstrain from tannery effluent Lab scale production of PHBusing the isolated bacterial strain uses spent wash as the solecarbon source Degradation of organic pollutants in termsof spent wash color uses PHB produced using the isolatedbacterial strain

2 Materials and Methods

21 Collection of Tannery Effluent Sample The tannery efflu-ent sample was collected from Pallavaram Tanners IndustrialEffluent Treatment Co (PTIETC) located near Chromepet

Chennai India This facility treats 3000m3day of tanneryeffluent from the leather processing industrial cluster locatednearby Sample from the activated sludge tank were asepti-cally collected in sterilized glass bottles and transported tothe laboratory and stored in the refrigerator at 4∘C

22 Collection of Distillery Effluent Sample The distilleryeffluent sample was collected from Trichy Distilleries andChemicals Limited (TDCL) located near the city of Tiruchi-rappalli India The collected effluent was immediatelybrought to the laboratory and stored in the refrigerator at 4∘C[15 16] until further use in order to avoid any deterioration inthe physicochemical property of the spent wash

23 Isolation of Metal Tolerant Bacterial Strain from TanneryEffluent The metal tolerant bacterial strain was isolatedby selection pressure method [17] Chromium in the formof potassium dichromate (K

2Cr2O7) was added in varying

concentrations of 10ndash2000 ppm to sterile nutrient agar (pH70) The plates were loaded with 500 120583L of raw effluentand the media was cast by pour-plate method The coloniesdeveloped were counted after 3ndash7 days of incubation at 28∘CIt is possible that some of the organisms die off due topour-plate method Consequently the numbers of Cr (VI)resistant bacterial colonies able to grow were viewed onrelative or comparative basis The increasing concentrationof chromium in the growth medium was given as a stress toresist the growth of the microorganisms The strain capableof growing at maximum concentration was isolated Theisolated bacterial strain was identified with reference toBergeyrsquos Manual of Determinative Bacteriology [18]

24 Molecular Characterization The 24-hour fresh Pseudo-monas sp culture was taken for genomic DNA extractionbased on isolation protocol described by Pitcher et al [19]The extracted DNA sample was run on 1 agarose gelwith 1 k standard marker acquired from Bangalore GeneiPrivate Limited India The universal primers were usedto amplify the 16S rRNA gene region The PCR ampli-fication of 20 120583L reaction mixture containing 1 120583L of thetemplate primers 2120583L of forward primer U3 (51015840AGT-GCCAGCAGCCGCGGTAA31015840) 2 120583L of reverse primer U4(51015840AGGCCCGGGAACGTATTCAC31015840) [20] 12 120583L of assaybuffer 1 120583L of Taq DNA polymerase and 2 120583L of dNTP mixThe amplification was carried out in Thermal Cycler for 35cycles using the following reaction conditions namely initialdenaturation of DNA at 95∘C for 5 minutes denaturation ofDNA at 95∘C for 30 seconds primer annealing at 45∘C for90 seconds and primer extension at 72∘C for 1 minute Theamplified PCR product was mixed with 2120583L of gel loadingbuffer and 1 agarose gel was cast The samples were loadedalong with 2 120583L of 1 kb DNA ladder as a molecular markerThe gel was run and examined on a UV transilluminator tovisualize the bands PCR products were purified by using EZ-10 spin column PCR purification kit and it was sequenced

25 Production of PHB Vincent [21] proposed the com-position of minerals and nutrients to be used in yeastextract mannitol (YEM) broth for the production of PHB

BioMed Research International 3

Acetyl-CoA Acetyl-CoA

Acetoacetyl-CoA

Acetoacetyl-CoAreductase

(R)-3-Hydroxybutyryl-CoA

PHA-synthaseHS-CoA

Polyhydroxybutyrate (PHB)

HS-CoAKetothiolase (PhaA)

NADPH + H+

NADP+

Figure 1 Biosynthetic pathway of Polyhydroxybutyrate (PHB)

The isolated and identified bacterial strain from tanneryeffluent was used for the production of PHB Yeast extractmannitol (YEM) broth (gL) consists of following ingre-dients mannitol 10 g KH

2PO4 05 g MgSO

4sdot7H2O 02 g

NaCl 01 g tryptone 25 g peptone 25 g yeast extract 25 gThe pH of the medium was adjusted to 70 with dilute HClThe batch production of PHB was carried out in 250mLErlenmeyer flasks containing 100mL of culture mediumThetemperature was maintained at 30∘C and the culture wasagitated at 110 rpm The production medium was inoculatedwith a loopful of isolated bacterial culture The biosyntheticpathway of PHB is shown in Figure 1

26Harvesting andAssay of PHB Theisolatedmetal tolerantbacterial strain was cultured in YEM broth at 30∘C for 48hours in an incubator shaker Cultures at stationary phase ofgrowth were centrifuged at 6000timesg for 45min The cell-freesupernatant was discarded The cell pellets were suspendedin 5mL of deionised water and homogenized for 2min ina sonicator bath To 2mL of the cell suspension 2mL of2N HCl was added and boiled for 120min in a water bathThe tubes were centrifuged at 6000timesg for 20min To obtainprecipitate 5mL of chloroform was added The test tubescontaining the suspension were left overnight at 28∘C ona shaker at 150 rpm The contents of the test tubes werecentrifuged at 6000timesg for 20 minutes and 01mL of chloro-form extract was dried at 50∘C About 5mL of concentratedsulfuric acid was added and heated at 100∘C in water bathfor 20min After cooling to room temperature the amountof PHB was determined using UV-Vis spectrophotometer ata corresponding wavelength of 235 nm The schematic step-wise procedure for PHB harvesting is shown in Figure 2

27 Determination of Dry Cell Weight The total dry weight(total biomass) was determined by harvesting washingdrying to constant volume and weighing The non-PHB dry

Polyhydroxybutyrate (PHB)

(30∘C 48 hours)

Centrifuged at for 45 minutes

Centrifuged at for 20 minutes

Centrifuged at for 20 minutes

Cell pellets suspended in 5mLdeionised water sonicated for 2min

Incubated with 2N HCl for 2 hours

5mL chloroform was added for precipitation

Incubated at 28∘C 150 rpm 12h

5mL conc sulfuric acid was addedand heated at 100∘C for 20min

50∘CChloroform extract dried at

Growth in renewable carbon source

6000timesg

6000timesg

6000timesg

Figure 2 Schematic flow diagram representing harvesting andpurification of PHB

weight (non-PHB biomass) was calculated from the total dryweight and the PHB content using the following equation

Non-PHB dry weight = total dry weight

times(100 minusPHB)100

(1)

28 Effect of Different Carbon Sources on PHB ProductionTheusage ofmannitol in YEMmediumbrothwas replaced by

4 BioMed Research International

Figure 3 Microbial colony developed at 1000 ppm of K2Cr2O7dosage concentration

other carbon sources such as glucose fructose dextrose andsucrose in the growth medium Peptone and tryptone werekept as constant nitrogen sources Based on the well-knownfact that molasses is rich in carbon source and inexpensivetrials were performed in which the expensive carbon sourcehas been replaced by inexpensivemolassesThe PHB yield fordifferent carbon sources and molasses was determined

29 Spent Wash Decolorization Studies The batch colorremoval experiments were performed in Erlenmeyer flasks(250mL volume) containing 100mL of raw spent wash Anappropriate dosage of as-synthesized PHB and 48-hour-oldbacterial culture was added as listed below

(1) 2mL of Pseudomonas aeruginosa culture(2) 2mL of PHB synthesized using the isolated strain(3) 2mL (1 1 ratio) of PHB and Pseudomonas aeruginosa

culture

The batch vessels were shifted to an incubator shaker andthe flasks were mildly shaken at 50 rpm Color reduction wasmonitored for 120 h Aliquots of samples were withdrawn andcentrifuged at 10000timesg for 10min to remove the suspendedparticles Color removal was measured at a characteristicwavelength of 475 nm using UV-Visible spectrophotometer(Spectroquant Pharo 300 Merck)

The color removal efficiency was calculated by

Color removed () =1198620minus 119862119905

1198620

times 100 (2)

where 1198620and 119862

119905are the initial absorbance and absorbance at

time 119905 for spent wash effluent at a characteristic wavelengthof 475 nm [22 23]

3 Results and Discussion

31 Isolation of Metal Tolerant Strain By selection pressuremethod the most tolerant bacterial strain was isolated from

tannery effluentThis strainwas found to tolerate amaximumconcentration of 1000 ppm (1000 120583gmL) of K

2Cr2O7 when

cultured in nutrient agar media containing K2Cr2O7as

shown in Figure 3 This method is to enhance the selectionpressure thereby reducing the number of surviving speciesand only to obtain the organism that can withstand suchhigh concentration (1000 ppm) of K

2Cr2O7 At lower concen-

trations numerous well developed colonies were visualizedBut at 1000 ppm of concentration only very few numbersof colonies were formed These highly tolerant colonieswere subcultured and preserved for identification molecularcharacterization of the strain and production of secondarymetabolite

32 Identification of Isolated Bacterial Strain The microor-ganism isolated by the selection pressure method was identi-fied by performing morphological microbial and biochemi-cal tests and the results were compared with Bergeyrsquos Manualof Determinative Bacteriology The colonies formed by theisolated strain were irregular circular in shape with flatcolony elevation with uneven or rough colony margin anddull white to mild beige in color The microorganisms wereidentified to be Gram-negative motile rods as shown inFigure 4 The strain isolated tested positive in catalase testdue to the rapid evolution of gas bubbles when a drop ofH2O2was placed on the bacterial colony showing that there

was an evolution of oxygen and the strain is aerobic Whensubjected to oxidase test the result was positive This is dueto the formation of dark blue purple colorwhich indicates thepresence of cytochrome c oxidase Indole test gave a negativeresult as there was no formation of the cherry red coloredringwhenKovacrsquos reagentwas added to the incubated culturePhenol red test result was negative as the isolated straincannot ferment any of the sugars like glucose sucrose orlactose So there was neither a change in color nor formationand collection of gas inside the inverted Durhamrsquos tubesThe result was methyl red negative upon performing methylred test as there was no red color formation upon additionof methyl red indicator which denotes the fact that the pH

BioMed Research International 5

remains above 60 Formation of colorless colonies was seenwhen they were grown on EMB and MacConkey agar platesThis is due to the reason that the organism cannot fermentlactose sugars The biochemical tests and the correspondingresults are tabulated in Table 1

33 Molecular Characterization The PCR sequenced prod-uct was identified using Bioinformatics tool BLAST andPseudomonas aeruginosa gene for 16S rRNA partial sequencewith 98 query coverage and 99 identity with expectedvalue of zero was found This confirmed that the organismis Pseudomonas aeruginosa The sequence is given as followsand the BLAST results are shown in Figure 5

GCAGGCCTAACACATGCAAGTCGAGCGGAT-GAAGGGAGCTTGCTCCTGGATTCAGCGGCGGAC-GGGTGAGTAATGCCTAGGAATCTGCCTGGTAGT-GGGGGATAACGTCCGGAAACGGGCGCTAATACC-GCATACGTCCTGAGGGAGAAAGTGGGGGATCTT-CGGACCTCACGCTATCAGATGAGCCTAGGTCGG-ATTAGCTAGTTGGTGGGGTAAAGGCCTACCAAG-GCGACGATCCGTAACTGGTCTGAGAGGATGATC-AGTCACACTGGAACTGAGACACGGTCCAGACTC-CTACGGGAGGCAGCAGTGGGGAATATTGGACAA-TGGGCGAAAGCCTGATCCAGCCATGCCGCGTGT-GTGAAGAAGGTCTTCGGATTGTAAAGCACTTTA-AGTTGGGAGGAAGGGCAGTAAGTTAATACCTTG-CTGTTTTGACGTTACCAACAGAATAAGCACCGG-CTAACTTCGTGCCAGCAGCCGCGGTAATACGAA-GGGTGCAAGCGTTAATCGGAATTACTGGGCGTA-AAGCGCGCGTAGGTGGTTCAGCAAGTTGGATGT-GAAATCCCCGGGCTCAACCTGGGAACTGCATCC-AAAACTACTGAGCTAGAGTACGGTAGAGGGTGG-TGGAATTTCCTGTGTAGCGGTGAAATGCGTAGA-TATAGGAAGGAACACCAGTGGCGAAGGCGACCA-CCTGGACTGATACTGACACTGAGGTGCGAAAGC-GTGGGGAGCAAACAGGATTAGATACCCTGGTAG-TCCACGCCGTAAACGATGTCGACTAGCCGTTGG-GATCCTTGAGATCTTAGTGGCGCAGCTAACGCG-ATAAGTCGACCGCCTGGGGAGTACGGCCGCAAG-GTTAAAACTCAAATGAATTGACGGGGGCCCGCA-CAAGCGGTGGAGCATGTGGTTTAATTCGAAGCA-ACGCGAAGAACCTTACCTGGCCTTGACATGCTG-AGAACTTTCCAGAGATGGATTGGTGCCTTCGGG-AACTCAGACACAGGTGCTGCATGGCTGTCGTCA-GCTCGTGTCGTGAGATGTTGGGTTAAGTCCCGT-AACGAGCGCAACCCTTGTCCTTAGTTACCAGCA-CCTCGGGTGGGCACTCTAAGGAGACTGCCGGTG-ACAAACCGGAGGAAGGTGGGGATGACGTCAAGT-CATCATGGCCCTTACGGCCAGGGCTACACACGT-GCTACAATGGTCGGTACAAAGGGTTGCCAAGCC-GCGAGGTGGAGCTAATCCCATAAAACCGATCGT-AGTCCGGATCGCAGTCTGCAACTCGACTGCGTG-AAGTCGGAATCGCTAGTAATCGTGAATCAGAAT-GTCACGGTGAATACGTTCCCGGGCCTTGTACAC-ACCGCCCGTCACACCATGGGAGTGGGTTGCTCC-AGAAGTAGCTAGTCTAACCGCAAGGGGGACGGT-TACCACGGAGTGATTCATGACTGGGGTGAAGTC-GTAACAAGGTA

Figure 4 Gramrsquos staining showing Gram-negative rods of isolatedPseudomonas aeruginosa

34 Production of Polyhydroxybutyrate (PHB) by Using theIsolated Bacterial Strain Pseudomonas aeruginosa Gram-negative motile rod shaped bacteria were able to synthesizePolyhydroxybutyrate (PHB) as an intracellular secondarymetabolite which is a resultant product due to the physiolog-ical stress occurring due to the availability of excess amountof carbon source and limited availability of other mineralsespecially phosphate or nitrogen It has been suggested thatammonia limited cultures of Pseudomonas aeruginosa wereunable to regulate fully the rate at which they take up glucoseparticularly when growing at the low availability of mineralsAs a result they form copious amounts of exopolysaccharideboth to overcome the potentially deleterious osmotic effectsof accumulating surplus intracellular metabolites and to con-sume some of the surplus ATP generated by the oxidation ofthese metabolites [24ndash26] However unlike exopolysaccha-ride PHB is an intracellular product and therefore addition-ally provides a means of storing excess carbon and reducingpower for future use [27] In this context it is interestingto note that Pseudomonas aeruginosa can synthesize PHBor other Polyhydroxyalkanoates exopolysaccharide andorvarious organic acids as alternative products after losing itsability to make exopolysaccharide or PHB respectively byfollowing natural strain degeneration ormutagenesis [25 28]

35 Effect of Different Carbon Sources on PHB ProductionTheyield of PHBbased on various carbon sourceswas studiedand the values along with standard deviation is tabulatedin Table 2 When the carbon source mannitol in the YEMmedium was replaced by molasses a maximum yield of 70PHB was obtained This research finding was a success as themolasses were used and the cost due to the use of mannitolcan also be avoided This is an economical initiative of usingmolasses as a source of carbon in the growth medium ofPseudomonas aeruginosa

The Dunnettrsquos multiple comparison test was used to findthe statistical significance of the various carbon sources incomparison with the control (YEM) In Table 3 the values

6 BioMed Research International

Color key for alignment scores

Query

1 250 500 750 1000 1250

NR_074828 Pseudomonas aeruginosa PAO 1 strain PAO1 16S ribosomal = 2697 E = 0

lt40 ge20040ndash50 50ndash80 80ndash200

SR

Figure 5 BLAST results for the isolated bacterial strain Pseudomonas aeruginosa

Table 1 Biochemical and morphological characterization of isolated bacterial strain

Biochemical test Result Morphology ResultGram staining minus Colony shape Irregular roundCatalase test + Colony elevation FlatOxidase test + Colony size (mm) 25Indole test minus Colony margin SerratedPhenol red test minus Colony color Dull whiteMethyl red test minus Motility MotileGrowth on EMB agar minus Cell shape RodGrowth on MacConkey agar minus

Table 2 Effect of various carbon sources on PHB production with standard deviation values

Carbon source Dry cell weight (gL) SD Amount of PHB (gL) SD PHB yield () SDGlucose 022 0007 0026 00007 1182 0049Sucrose 023 001 0049 00008 2130 0141Fructose 132 00282 0072 00021 545 0219Molasses 021 00131 0147 00014 700 0707Control (YEM) 028 00141 0060 00135 2143 00636SD standard deviation

Table 3 Effect of various carbon sources on PHB production with standard deviation values

Dunnettrsquos multiple comparison test Significant Summary Adjusted 119901 valueDry cell weight

Control (YEM) versus glucose Yes lowast 00178Control (YEM) versus sucrose No ns 00683Control (YEM) versus fructose Yes lowastlowastlowastlowast lt00001Control (YEM) versus molasses Yes lowast 00235

Amount of PHBControl (YEM) versus glucose Yes lowastlowast 00029Control (YEM) versus sucrose No ns 00682Control (YEM) versus fructose No ns 09459Control (YEM) versus molasses Yes lowastlowastlowast 00002

yield of PHBControl (YEM) versus glucose Yes lowastlowastlowastlowast lt00001Control (YEM) versus sucrose No ns gt09999Control (YEM) versus fructose Yes lowastlowastlowastlowast lt00001Control (YEM) versus molasses Yes lowastlowastlowastlowast lt00001ns not significant

BioMed Research International 7

with 119901 lt 005 are considered significant with symbol lowastindicating mild significance and symbol lowast lowast lowastlowast indicatingmore significance in comparison with the control medium

36 Effect of Time on PHBProduction It was found that whenmolasses were used as the carbon source in YEM mediuminstead of mannitol at the end of 48 hours the PHB yieldwas 70 After 48 hours of incubation there was a decreasein the PHB yield and increase in the viscosity of the mediumThe increase in the viscosity of the growth medium resultedin a limited oxygen transfer rate and caused the fall of PHBsynthesis and accumulation inside the bacterial cells ThePHB yield decreased to 32 after 72 hours of incubation and18 after 120 hours of incubation Even the dry cell weightwas increased up to 120 hours The decrease in the PHBcontent explained that the bacteria have used the producedPHB as a source of carbon to survive due to the unavailabilityof the carbon sourceThePHByield alongwith the standarddeviation values has been plotted as shown in Figure 6

37 Spent Wash Decolorization Study This initiative of test-ing the effect of the isolated bacterial culture and the as-synthesized PHB on spent wash decolorization was per-formed as a trial and very positive and welcoming resultswere obtained as shown in Figure 7 At the end of five-daybatch study a combination consisting of 2mL (1 1 ratio) ofPHB and Pseudomonas aeruginosa culture was able to achieve9277 spent wash color removal whereas there was onlya minimal color reduction (2530 and 1358) resultingwhen the spent wash was treated with microorganism andPHB individuallyThe increased color removal was due to thephenomenon that the Gram-negative bacteria Pseudomonasaeruginosa possess negative surface charge When thesebacterial cultures were added to the effluent along withthe PHB the bacteria bind to the PHB hence forminga biofilm and thereby also act as an ion exchange thatattracts the suspended organic particles to get bound to thebiofilm This biofilm acts as a support material and favors asuitable condition for the further growth and developmentof the bacteria Thus the synergic actions of the PHB andthe microorganism were found to be the most capable ofperforming spent wash decolorization

38 Research Outcome The positive results of this researchcould lead to a more advanced technique and applicationwhere the microbially produced PHB can be used as ananobiomaterial possessing tunable propertieswith a focusedapplication for binding and removal of heavy metals fromaqueous industrial effluents As the synthesis of biopolymerrelies on a principle of single phase transition scaling up theproduction process could be of a less intensive task henceproviding an ecofriendly technology for pollutant removal

4 Conclusion

In this research paper bacterial strain possessing tolerance tohigh concentrations of chromium was isolated from tanneryeffluent The isolated strain was identified as Pseudomonasaeruginosa by biochemical and molecular characterization

Dry cell weight

Amount of PHB

Control (YEM)

Control (YEM)

Glucose

Glucose

SucroseCarbon sources

Sucrose

Fructose

Fructose

Molasses

Molasses

Control (YEM)

Control (YEM)

Glucose

Glucose

SucroseCarbon sources

PHB80

60

40

20

0

Yiel

d (

)

Sucrose

Fructose

Fructose

Molasses

Molasses

Control (YEM)

Control (YEM)

Glucose

Glucose

SucroseCarbon sources

Sucrose

Fructose

Fructose

Molasses

Molasses

(gL

)

00

000

005

010

(gL

)

015

020

05

10

15

Figure 6 Bar charts with standard deviation values for dry cellweight amount of PHB and yield of PHB

8 BioMed Research International

PseudomonasPHBPseudomonas + PHB

Time (h)0

010

10

20

20

30

30

40

40

50

50

60

60

70

70

80

80

90

100

Col

or re

mov

ed (

)

90

Figure 7 Effect of time on color removal by microbial culturePHB and combination of microbial culture and PHB

Efforts were taken to synthesize Polyhydroxybutyrate (PHB)using the isolated bacterial strain Mannitol an expensivecarbon source for the bacterial growth culture media wasreplaced with inexpensive molasses The exopolysaccharidesaccumulated by the bacterial cells were harvested and sep-arated Optimization of suitable quantities of as-synthesizedPHB and microbial culture was tested to evaluate the colorremoval efficiency The results showed that Pseudomonasaeruginosa exhibited a synergistic effect in combination (1 1ratio) with the biopolymer towards spent wash decoloriza-tion Lab scale optimization experiments resulted in 9277removal of spent wash color after 96 hours of treatmentwhereas there was only a limited color reduction (2530 and1358) observed when the same concentration and volumeof spent wash was treated with Pseudomonas aeruginosaculture and PHB individually

Conflict of Interests

The authors report no conflict of interests

Acknowledgments

Charles David is supported by the Technical EducationQuality Improvement Program (TEQIP) Phase II a WorldBank initiative The authors thank TEQIPminusII and NationalInstitute of Technology Tiruchirappalli Tamil Nadu India

References

[1] E C Bernardo R Egashira and J Kawasaki ldquoDecolorizationof molassesrsquo wastewater using activated carbon prepared fromcane bagasserdquo Carbon vol 35 no 9 pp 1217ndash1221 1997

[2] V P Migo M Matsumura E J Del Rosario and H KataokaldquoDecolorization of molasses wastewater using an inorganic

flocculantrdquo Journal of Fermentation and Bioengineering vol 75no 6 pp 438ndash442 1993

[3] N Naik K S Jagadeesh and M N Noolvi ldquoEnhanced degra-dation of melanoidin and caramel in biomethaneted distilleryspent wash by micro-organisms isolated from mangrovesrdquoIranica Journal of Energy and Environment vol 1 pp 347ndash3512010

[4] P Manisankar C Rani and S Viswanathan ldquoEffect of halidesin the electrochemical treatment of distillery effluentrdquo Chemo-sphere vol 57 no 8 pp 961ndash966 2004

[5] Y Satyawali and M Balakrishnan ldquoRemoval of color frombiomethanated distillery spentwash by treatment with activatedcarbonsrdquo Bioresource Technology vol 98 no 14 pp 2629ndash26352007

[6] Y Zhou Z Liang and Y Wang ldquoDecolourization and CODremoval of secondary yeast wastewater effluents by coagulationusing aluminum sulphatrdquo Desalination vol 225 no 1ndash3 pp301ndash311 2008

[7] R K Prasad ldquoColor removal fromdistillery spent wash throughcoagulation using Moringa oleifera seeds use of optimumresponse surfacemethodologyrdquo Journal of HazardousMaterialsvol 165 no 1ndash3 pp 804ndash811 2009

[8] G S Kumar S K Gupta and S Gurdeep ldquoAnaerobic hybridreactormdasha promising technology for the treatment of distilleryspent washrdquo Journal of Indian School of Mines vol 11 pp 25ndash382007

[9] S Venkata Mohan G Mohanakrishna S V Ramanaiah and PN Sarma ldquoSimultaneous biohydrogen production and wastew-ater treatment in biofilm configured anaerobic periodic discon-tinuous batch reactor using distillery wastewaterrdquo InternationalJournal of Hydrogen Energy vol 33 no 2 pp 550ndash558 2008

[10] S Mohana B K Acharya and D Madamwar ldquoDistilleryspent wash treatment technologies and potential applicationsrdquoJournal of Hazardous Materials vol 163 no 1 pp 12ndash25 2009

[11] S Y Lee ldquoBacterial polyhydroxyalkanoatesrdquo Biotechnology andBioengineering vol 49 no 1 pp 1ndash14 1996

[12] J Choi and S Y Lee ldquoFactors affecting the economics ofpolyhydroxyalkanoate production by bacterial fermentationrdquoApplied Microbiology and Biotechnology vol 51 no 1 pp 13ndash211999

[13] A J Anderson and E A Dawes ldquoOccurrence metabolismmetabolic role and industrial uses of bacterial polyhydrox-yalkanoatesrdquo Microbiological Reviews vol 54 no 4 pp 450ndash472 1990

[14] J Varani M Dame T F Beals and J A Wass ldquoGrowth of threeestablished cell lines on glass microcarriersrdquo Biotechnology andBioengineering vol 25 no 5 pp 1359ndash1372 1981

[15] Y Yavuz ldquoEC and EF processes for the treatment of alcoholdistillery wastewaterrdquo Separation and Purification Technologyvol 53 no 1 pp 135ndash140 2007

[16] C David R Narlawar andMArivazhagan ldquoPerformance eval-uation of Moringa oleifera seed extract (MOSE) in conjunctionwith chemical coagulants for treating distillery spent washrdquoIndian Chemical Engineer vol 1 pp 1ndash12 2015

[17] I Ghanem M Orfi and M Shamma ldquoBiodegradation ofchlorphyrifos by Klebsiella sp isolated from an activated sludgesample of waste water treatment plant in damascusrdquo FoliaMicrobiologica vol 52 no 4 pp 423ndash427 2007

[18] Bergeyrsquos Manual of Systematic Bacteriology Springer 2nd edi-tion 1985

BioMed Research International 9

[19] D G Pitcher N A Saunders and R J Owen ldquoRapid extractionof bacterial genomic DNAwith guanidium thiocyanaterdquo Lettersin Applied Microbiology vol 8 no 4 pp 151ndash156 1989

[20] G James ldquoUniversal bacterial identification by PCR and DNAsequencing of 16S rRNA generdquo in PCR for Clinical MicrobiologyM Schuller T P Sloots G S James C L Halliday and I WJ Carter Eds pp 209ndash214 Springer Science+Business MediaAmsterdam The Netherlands 2010

[21] J M Vincent ldquoA manual for the practical study of the root-nodule bacteriardquo in IBP Handbook 15 Blackwell ScientificPublishers Oxford UK 1970

[22] C David M Arivazhagan and F Tuvakara ldquoDecolorization ofdistillery spent wash effluent by electro oxidation (EC and EF)and Fenton processes a comparative studyrdquo Ecotoxicology andEnvironmental Safety 2015

[23] C Raghukumar and G Rivonkar ldquoDecolorization of molassesspent wash by the white-rot fungus Flavodon flavus isolatedfrom amarine habitatrdquoAppliedMicrobiology and Biotechnologyvol 55 no 4 pp 510ndash514 2001

[24] A Cornish J A Greenwood and CW Jones ldquoThe relationshipbetween glucose transport and the production of succinoglucanexopolysaccharide by Agrobacterium radiobacterrdquo Journal ofGeneral Microbiology vol 134 pp 3111ndash3122 1988

[25] S GWilliams J A Greenwood andCW Jones ldquoPhysiologicaland biochemical changes accompanying the loss of mucoidy byPseudomonas aeruginosardquoMicrobiology vol 142 no 4 pp 881ndash888 1996

[26] A J Rye J W Drozd C W Jones and J D Linton ldquoGrowthefficiency of Xanthomonas campestris in continuous culturerdquoMicrobiology vol 134 no 4 pp 1055ndash1061 1988

[27] P J Senior G A Beech G A Ritchie and E A DawesldquoThe role of oxygen limitation in the formation of poly-120573-hydroxybutyrate during batch and continuous culture ofAzotobacter beijerinckiirdquo Biochemical Journal vol 128 no 5 pp1193ndash1201 1972

[28] U Breuer J-U Ackermann and W Babel ldquoAccumula-tion of poly(3-hydroxybutyric acid) and overproduction ofexopolysaccharides in amutant of amethylotrophic bacteriumrdquoCanadian Journal of Microbiology vol 41 no 1 pp 55ndash59 1995

BioMed Research International 3

Acetyl-CoA Acetyl-CoA

Acetoacetyl-CoA

Acetoacetyl-CoAreductase

(R)-3-Hydroxybutyryl-CoA

PHA-synthaseHS-CoA

Polyhydroxybutyrate (PHB)

HS-CoAKetothiolase (PhaA)

NADPH + H+

NADP+

Figure 1 Biosynthetic pathway of Polyhydroxybutyrate (PHB)

The isolated and identified bacterial strain from tanneryeffluent was used for the production of PHB Yeast extractmannitol (YEM) broth (gL) consists of following ingre-dients mannitol 10 g KH

2PO4 05 g MgSO

4sdot7H2O 02 g

NaCl 01 g tryptone 25 g peptone 25 g yeast extract 25 gThe pH of the medium was adjusted to 70 with dilute HClThe batch production of PHB was carried out in 250mLErlenmeyer flasks containing 100mL of culture mediumThetemperature was maintained at 30∘C and the culture wasagitated at 110 rpm The production medium was inoculatedwith a loopful of isolated bacterial culture The biosyntheticpathway of PHB is shown in Figure 1

26Harvesting andAssay of PHB Theisolatedmetal tolerantbacterial strain was cultured in YEM broth at 30∘C for 48hours in an incubator shaker Cultures at stationary phase ofgrowth were centrifuged at 6000timesg for 45min The cell-freesupernatant was discarded The cell pellets were suspendedin 5mL of deionised water and homogenized for 2min ina sonicator bath To 2mL of the cell suspension 2mL of2N HCl was added and boiled for 120min in a water bathThe tubes were centrifuged at 6000timesg for 20min To obtainprecipitate 5mL of chloroform was added The test tubescontaining the suspension were left overnight at 28∘C ona shaker at 150 rpm The contents of the test tubes werecentrifuged at 6000timesg for 20 minutes and 01mL of chloro-form extract was dried at 50∘C About 5mL of concentratedsulfuric acid was added and heated at 100∘C in water bathfor 20min After cooling to room temperature the amountof PHB was determined using UV-Vis spectrophotometer ata corresponding wavelength of 235 nm The schematic step-wise procedure for PHB harvesting is shown in Figure 2

27 Determination of Dry Cell Weight The total dry weight(total biomass) was determined by harvesting washingdrying to constant volume and weighing The non-PHB dry

Polyhydroxybutyrate (PHB)

(30∘C 48 hours)

Centrifuged at for 45 minutes

Centrifuged at for 20 minutes

Centrifuged at for 20 minutes

Cell pellets suspended in 5mLdeionised water sonicated for 2min

Incubated with 2N HCl for 2 hours

5mL chloroform was added for precipitation

Incubated at 28∘C 150 rpm 12h

5mL conc sulfuric acid was addedand heated at 100∘C for 20min

50∘CChloroform extract dried at

Growth in renewable carbon source

6000timesg

6000timesg

6000timesg

Figure 2 Schematic flow diagram representing harvesting andpurification of PHB

weight (non-PHB biomass) was calculated from the total dryweight and the PHB content using the following equation

Non-PHB dry weight = total dry weight

times(100 minusPHB)100

(1)

28 Effect of Different Carbon Sources on PHB ProductionTheusage ofmannitol in YEMmediumbrothwas replaced by

4 BioMed Research International

Figure 3 Microbial colony developed at 1000 ppm of K2Cr2O7dosage concentration

other carbon sources such as glucose fructose dextrose andsucrose in the growth medium Peptone and tryptone werekept as constant nitrogen sources Based on the well-knownfact that molasses is rich in carbon source and inexpensivetrials were performed in which the expensive carbon sourcehas been replaced by inexpensivemolassesThe PHB yield fordifferent carbon sources and molasses was determined

29 Spent Wash Decolorization Studies The batch colorremoval experiments were performed in Erlenmeyer flasks(250mL volume) containing 100mL of raw spent wash Anappropriate dosage of as-synthesized PHB and 48-hour-oldbacterial culture was added as listed below

(1) 2mL of Pseudomonas aeruginosa culture(2) 2mL of PHB synthesized using the isolated strain(3) 2mL (1 1 ratio) of PHB and Pseudomonas aeruginosa

culture

The batch vessels were shifted to an incubator shaker andthe flasks were mildly shaken at 50 rpm Color reduction wasmonitored for 120 h Aliquots of samples were withdrawn andcentrifuged at 10000timesg for 10min to remove the suspendedparticles Color removal was measured at a characteristicwavelength of 475 nm using UV-Visible spectrophotometer(Spectroquant Pharo 300 Merck)

The color removal efficiency was calculated by

Color removed () =1198620minus 119862119905

1198620

times 100 (2)

where 1198620and 119862

119905are the initial absorbance and absorbance at

time 119905 for spent wash effluent at a characteristic wavelengthof 475 nm [22 23]

3 Results and Discussion

31 Isolation of Metal Tolerant Strain By selection pressuremethod the most tolerant bacterial strain was isolated from

tannery effluentThis strainwas found to tolerate amaximumconcentration of 1000 ppm (1000 120583gmL) of K

2Cr2O7 when

cultured in nutrient agar media containing K2Cr2O7as

shown in Figure 3 This method is to enhance the selectionpressure thereby reducing the number of surviving speciesand only to obtain the organism that can withstand suchhigh concentration (1000 ppm) of K

2Cr2O7 At lower concen-

trations numerous well developed colonies were visualizedBut at 1000 ppm of concentration only very few numbersof colonies were formed These highly tolerant colonieswere subcultured and preserved for identification molecularcharacterization of the strain and production of secondarymetabolite

32 Identification of Isolated Bacterial Strain The microor-ganism isolated by the selection pressure method was identi-fied by performing morphological microbial and biochemi-cal tests and the results were compared with Bergeyrsquos Manualof Determinative Bacteriology The colonies formed by theisolated strain were irregular circular in shape with flatcolony elevation with uneven or rough colony margin anddull white to mild beige in color The microorganisms wereidentified to be Gram-negative motile rods as shown inFigure 4 The strain isolated tested positive in catalase testdue to the rapid evolution of gas bubbles when a drop ofH2O2was placed on the bacterial colony showing that there

was an evolution of oxygen and the strain is aerobic Whensubjected to oxidase test the result was positive This is dueto the formation of dark blue purple colorwhich indicates thepresence of cytochrome c oxidase Indole test gave a negativeresult as there was no formation of the cherry red coloredringwhenKovacrsquos reagentwas added to the incubated culturePhenol red test result was negative as the isolated straincannot ferment any of the sugars like glucose sucrose orlactose So there was neither a change in color nor formationand collection of gas inside the inverted Durhamrsquos tubesThe result was methyl red negative upon performing methylred test as there was no red color formation upon additionof methyl red indicator which denotes the fact that the pH

BioMed Research International 5

remains above 60 Formation of colorless colonies was seenwhen they were grown on EMB and MacConkey agar platesThis is due to the reason that the organism cannot fermentlactose sugars The biochemical tests and the correspondingresults are tabulated in Table 1

33 Molecular Characterization The PCR sequenced prod-uct was identified using Bioinformatics tool BLAST andPseudomonas aeruginosa gene for 16S rRNA partial sequencewith 98 query coverage and 99 identity with expectedvalue of zero was found This confirmed that the organismis Pseudomonas aeruginosa The sequence is given as followsand the BLAST results are shown in Figure 5