• Front wheel or 4 wheel drive • more capacity • More control • more productivity • more dependability

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Self-propelled Chipspreaders are used by both contractors andmunicipalities. The main function of a chipspreader is to uniformlydistribute cover aggregate into the hot liquid asphalt sprayed by anasphalt distributor truck.

It is very important that the chipspreader be designed and constructedto apply many different size aggregates at different speeds.

With that in mind, let’s take a close look at the design features of theEtnyre self-propelled ChipSpreader.

3

Here’s how the ChipSpreader works

Truck backs to spreader and automatically hitchesitself, raises dump bed and releases tail gate.

Stone flows into the rear hopper where it is pickedup by two conveyor belts.

The conveyor belts transfer the material to thespread hopper, which is equipped with a series ofradial gates that are readily adjustable to the desiredspread width.

As the spread hopper is loaded, the ChipSpreaderis started and pulls the truck behind it.

Application rate computer controls the main gatecontrol opening and the speed of the ChipSpreader.

The ChipSpreader operator has a clear view toinsure an even longitudinal joint.

When truck is empty, it is released by the driver,and another truck attaches itself and dumps its loadwhile the ChipSpreader keeps spreading.

4

Why hydrostatic drive?

1. Hydrostatic drive features infinitely adjustable working speeds.

2. Computer control for accurate and repeatable chip applicationrate. Chip application is automatically controlled as groundspeed increases or decreases.

3. Hydrostatic drive system provides smooth starting and stoppingon steep grades with heavy loads. Less likelihood of tire spinon newly chipped road surfaces.

4. Optional Front Wheel or 4-wheel drive available (see page 11for more details).

Hydrostatic Drive

5

There are six major systems in ourself-propelled ChipSpreader.

1. Two-section frame assembly2. Aggregate handling system3. Power train4. Hydrostatic drive system5. Control system6. Front hopper spread system

Let’s take a closer look at eachof these areas.

6

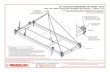

1 Frame Assembly

• Complete frame is all 3/16” steelconstruction.

• Heavy duty design to handle alltypes of dump trucks (single axle,tandem axle and tri-axle models).

New Etnyre two sectionframe assembly.

Upper Section• Both conveyors, right and left side

ladder and walkways, 95 gallonhydraulic oil reservoir, 72 gallon fueltank, rear hopper compartment.

Lower Section• Contains engine, hydrostatic drive

system and front and rear axleassemblies.

• Bolts to main frame section.

7

• Two 24" conveyor belts.

• Belt drive is powered by high torquehydraulic motors, directly coupled tothe head pulley.

• Hooded, adjustable aggregatedeflectors located at the head ofconveyor.

• Automatic conveyorcontrol on/off.

8

2 Aggregate Handling System

9

Folding Bat Wing Rear Receiving Hopper

• Increased capacity.

• Improved utilization ofon board aggregatecapacity.

• Facilitates easy changeof aggregate types.

• Provides easy clean outof rear receivinghopper.

10

Available engines.• Cummins model 6BTA5.9 (200 h.p.)• Cummins model QSB (240 h.p.) Tier III

• 12 volt.

• Heavy duty cooling.

Hydrostatic Drive Pump

Auxiliary PressureCompensating Pump(s)

3 Power Train

11

4 Hydrostatic Drive System

• Direct hydrostatic FRONT wheel driveprovides smooth stopping and starting on steepgrades with heavy loads. Infinitely adjustabletravel speeds at full engine power and precisecontrols minimize the likelihood of tire spin onnewly chipped surfaces.

• Mechanical front wheel drive steer axle, fulloscillating, 75" wheel track, 20.4:1 gear ratio,25,000 lb. rated, single speed differential. Drivenby direct engine bell housing mounted 125 cchydrostatic pump and 160 cc hydrostatic motor.Rear axle is 25,000 lb. rated with 95" wheeltrack. Infinitely variable speed from 0 to 19.5M.P.H.

• Large 95 gallon hydraulic oil tank.

• Working speed is infinitely adjustable. Speedis controlled by a joystick. A separate panelcontrol provides infinite adjustment of maximumchipping speed, allowing the operator toconsistently match any job requirement.

• Faster travel between jobs. The hydrostaticsystem provides road speed to 19 m.p.h. (30kph) maximizing relocation efficiency. Singlespeed, no shifting, for both controlled chippingand faster road travel.

385/65R 22.5J wide base tires

B Conveyor / Belt Speed Controls

13

Conveyor• Conveyor controls have for operator controlled positions:

1. Off

2. Auto: In this position the conveyor on/off is automaticallycontrolled by sensor switches located above the fronthopper.

3. Front: In this center switch position the conveyor on/offis controlled at the front operator station only.

4. On

Belt Speed ControlsThis feature allows the operator located on the right catwalk

to vary the speed of each conveyor independently to providea uniform distribution of material to the front hopper. Valvesfor this operation are incorporated in the integrated circuit blockbetween the conveyors. Each valve has an adjustment knoband a locking ring.

This feature is particularly useful in doing shoulder work orin operations requiring less than full hopper width. It is alsouseful in smoothing out delivery of material to match the ratebeing spread. When properly adjusted, the conveyors shouldrun approximately 80% of the time with the hopper at maximumwidth and the ChipSpreader traveling at maximum speed forthe particular job.

C ChipSpreader Park/Drive Selector

14

Three Brake SystemsJoystick

Forward / Reverse

2 3

1

1) Hydrostatic.

The primary brakingsystem is inherent andbuilt into the hydrostaticdrive system.

2) Mechanical brakes.

Conventional mechanicalbrakes assist the operatorin controlling the startsand stops.

3) Parking Brake.

Used to hold the unit inpark. Automatically setswhenever the unit isstationary.

D Speed/Direction Control Handle

15

Speed/Direction Control Handle (joystick)

The control handle dictates the direction of travel (forward/reverse) as well as the rate of travel. The control handleincorporates position microswitches for neutral and reverse.The neutral microswitch provides the safety feature ofrequiring the control handle to be in the neutral position tostart the engine and also applies the brake lights. This switchalso insures the gates cannot be inadvertently applied whilethe control stick is in the neutral position. The reversemicroswitch activates the back up alarm when the controlhandle is moved in the reverse direction. The handle has adetent in the neutral position and an adjustable friction dragfor holding at any desired position other than neutral. Movingthe handle out of neutral 3 degrees in either direction willrelease the parking brake and begin to increase the speedin the direction the handle is being moved. Furthermovement in either direction will increase the speedproportionally until the handle reaches full stroke, at whichpoint the machine will hold the set point speed.

Stopping is always accomplished by returning the handleto neutral.

Decelerating is always accomplished by moving thehandle toward neutral. Upon reaching the neutral positionof the handle, the parking brake will automatically applyonce the machine has come to a complete stop.

JoystickForward / Reverse

E Computer Control

16

The computer varies the gate opening to maintain a presetapplication rate regardless of the ChipSpreader speed. Appli-cation accuracy is maintained when starting and stopping andwhen ChipSpreader speed is adjusted to meet job require-ments. Increased accuracy reduces aggregate expense andresults in an improved road surface.

The computer can store five different aggregate/ applica-tion rate combinations in memory. Application rate can bevaried infinitely or memory presets can be selected on the go.

The computer can also be set to control the ChipSpreader’sforward speed for consistent speed when following the dis-tributor.

Instrumentation includes a highly visible display to monitorengine, hydraulic oil temperature, fuel and speed. A systemsmonitor alerts the operator of abnormal conditions.

Automatic Application Rate and SpeedControl Computer

Additional screens display engine temperature, engine oilpressure, fuel, engine RPM, hydraulic oil temperature, en-gine hours and battery voltage.

Aggregate size, type

Large character, high contrast, illuminated display.

Preset speed when standing still and actualspeed when the ChipSpreader is moving.

The Etnyre Application Rate Computer is standard on2WD and 4WD hydrostatic ChipSpreaders.

Application rate

E Computer Control

17

Set-Up ScreenGround Speed Pick-Up Computer ControledGate Opening

Micro Processor

A preset and calibrated application rate is maintainedthroughout changes in forward ground speed.

F Front Spread Hopper Controls

18

Gate/Spreadroll Switch

The rocker switch controls both the spread roll and thecommand circuit for the gates. As described previously,this switch is active only when the control handle is out ofthe neutral position. With the control stick out of neutral,depressing the right side of the rocker switch will activatethe spreadroll and gate circuits. Centering the switchdeactivates the circuits. The left side of the switch willalso deactivate the circuits.

Aggregate Size Switch

The aggregate size switch determines the size of thematerial to be spread. Activating the switch up or downwill scroll the display through the available aggregateselections. The size shown on the display shouldapproximately match the size of stone to be used.

Application Rate Switch

The application rate switch adjusts the application rateset point in lb/yd2. Press the switch up to increase theapplication rate, and press it down to decrease the rate.The rate is adjustable "on the fly".

Gate Override Push-button

Push down to momentarily fully open the hopper gate toclear a jam. Upon releasing the button, the gate will returnto its original set point.

G Truck Hitch Control

19

Hitch Height Switch

Push up to raise the hitch, push down to lower the hitch.When the switch is released, the cylinder will hold the hitchat a given height. A spring provides vertical articulationbetween the ChipSpreader and the truck.

Hitch Release Push-Button

Push the hitch release push-button to disengage thesupply truck from the ChipSpreader. Hitch will automaticallyrelatch with next truck.

Release

Up

Down

H Hydraulic System for Conveyor / Hopper / Steering

20

1. Right Conveyor Motor

2. Left Conveyor Motor

3. Spread Roll andAgitator Motor

4. Gate Cylinder

5. Hydraulic PumpAxial piston, variable displacement pumpis direct crankshaft driven. Pressure andflow compensation provides constantspeeds under varing demands whilemaintaining optimum optimum efficiencyand low hydraulic oil temperature.

6. 95 Gallon Reservoir,two 10 micron absolute returnline filters, valves, 30 GPM

continuous flow cooler andpiping.

7. Gear PumpDedicated flow forsteering circuit.

8. BatwingCylinders

I Seat Console Control Feature is Standard Equipment

21

Infinite seat positions give the operator exceptional line of sight of all chipping functions.

Sliding Pedestal - Etnyre Exclusive Feature

OptionalPower Seat

Optional poweredseat and controlpanel movement fordual control operation

Allows for operation ofthe machine from eitherthe right or left side oranywhere in betweenwhile keeping all thecontrols in the samerelative position to theoperator.

22

• Quick disconnect drivemechanism for agitatorand spread roll.

• Driven by high torquehydraulic motor.

J Fixed Front Spread Hopper - available from 10' to 15' wideIncludes:

• 10’ wide standard spreadwidth (options to 15’spread width).

• Individual 6” & 12” gateswith adjustable, reversible,wear plates.

• Electric/hydraulic gangopening controlled fromoperator seat position.

Four 6” gates 1' gates Four 6” gates

23

• Total PowerIndividual gatecontrol fromoperators station.

K 1' Power Gates on Fixed Width Hopper

24

There are two major features offered by Etnyre that are very popularwith both contractor and municipal customers.

1. Hydrostatic 4 wheel drive package

2. Variable width front spreader hopper

Let’s take a closer look at these options.

Now we have a complete Etnyre ChipSpreader - ready to go to work.

25

Option 1 Hydrostatic 4 Wheel Drive

Hydrostatic4 Wheel Drive

Option Package.

Choose 4 WD for more traction, greaterflexibility.

Adding the 4 Wheel Drive package to yourChipSpreader gives you all the benefits of ourstandard model plus these productiveadvantages:

• Increased gradeability by up to100%. Protects newly chippedsurfaces by reducing the potentialfor tire spin on grades.

• More powerful, 240 H.P. Tier IIIdiesel engine standard with 4Wheel Drive package. More powerto handle difficult terrain and heavyloads.

26

Option 2 Variable Width Front Spreader Hopper

Hopper available in four sizes: 9'/18'Hopper system, extendable 9' to 18'10'/20' Hopper system, extendable 10' to 20'11'/22'Hopper system, extendable 11' to 22'12'/24' Hopper system, extendable 12' to 24'

• Two independent spread hoppers work in unison. Width variable on leftside, right side, or both sides at once.

• Full 4" hopper gate opening.

• Hopper controls located at both drivers seat and right front station.

• 12" diameter aggregate distribution augers with automatic controls.

• Electro-hydraulic control of spread rolls, auger drives and widthchanges.

The 4WD option is recommended for many variable hopper applications.

27

Standard Equipment SpecificationsVariable width two section hopper system with independent conveyor feedto each section. Hopper capacity of .08 cubic yards of aggregate per foot ofbox width. Spread rolls 6" machine welded heavy wall tubing. Spread rollsand augers hydraulically driven, activated by gate opening control. Oneradial gate for each hopper section. Gate openings graduated into .01"increments. Expanded metal in top of spread hopper except directly underconveyor hoods where there are replaceable grates. Controls for operationof hopper and conveyors located at both driver’s seat and right front station.Hydraulic cylinders and system to independently expand and retract eachhopper.

Infinite on the go width changes.Increase productivity and flexibility.One pass capability up to 24' wide.

The Etnyre variable width hopper hydraulically extendsand retracts while spreading to cover the entire road andshoulder in one pass. The hopper width is adjusted usinga control panel switch.

No parts to add or subtract.

No extra hopper extending beyond the spread width.

Unbeatable transportation convenience. The 9' to 18'spread hopper retracts to under 10' with the flip of aswitch and is ready for transport only seconds afterfinishing a job.

Variable Width Front Spreader Hopper

28

Standard Individual 1' Gates with Variable Hopper

• Infinitelyvariablespreadwidths.

• 1 footindividualpower gatecontrols.

31

Examine the EtnyreChipSpreader fromthe front, rear, oreither side.

Fixed HopperWeight, 20,000 pounds

(with 13’ hopper)Height, 106”

Width, with 13’ box - 14’Length, with box - 23’ 7”

Loaded Capacity, 6.1 cubic yardsMaximum Speed, 19 M.P.H.

Variable Width HopperWeight, 24,000 pounds

(with 12/24' hopper)Height, 106"Width, 13'-2"

Length, 24'-5 3/4"Loaded Capacity, 6.1 cubic yards

Maximum Speed, 19 M.P.H.

A functional, welldesigned unit foruse in bituminousroad constructionand maintenance.

Related Documents

![CHIP SPREADERS (SERIES DV+) - Wirtgen Group · 2021. 1. 28. · Type Availability Line spreader Disc spreader Spread width [m] Capacity [ltr.] HLS 150 DV+ 70i • 0,30 - 1,50 790](https://static.cupdf.com/doc/110x72/60d376e3c7e2b407ba6c6f3a/chip-spreaders-series-dv-wirtgen-group-2021-1-28-type-availability-line.jpg)