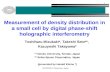

April 22, 2014 Biomaterial Science by Toshiharu Enomae 1 EG60411 Bio-Material Science Toshiharu Enomae Professor, PhD, Paper Device and Eco-friendly materials 2G103, 10:10-11:25, Tuesday Biomaterial Science(Schedule) # Date Date Date Date Content Content Content Content 1 4/15 History of papermaking 2 4/22 Pulps – Beating and fiber properties 3 5/9, Fri Pulps – Additives and functions 4 5/13 Papermaking processes & interfiber bonding 5 5/20 Paper– Structural and absorption properties 6 5/27 Paper– Mechanical and optical properties 7 6/3 Polysaccharide chemistry by Assoc Prof Akiko Nakagawa 8-9 6/10, 17 Pulping science and technology by Professor Hiroshi Ohi 10 6/24 Recent trend of paper science and technology Lecture information and contact Homepage of “Biomaterial Science (T. Enomae)” http://www.enomae.com/ → Handouts in lecture(講義資料) E-mail address → [email protected] for any questions and visit to laboratory (Bio-Agr. Bldg. 生農C209 or E201) Production of paper and paperboard 0 20 40 60 80 100 120 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 China USA Japan Germany Sweden Korea Canada Finland Brazil Indonesia India Thailand Production , million ton (A2) (A3) How to make paper From “wood” Paper Chip Pulp Waste paper Forest Wood (thinned out) (A4) Wood tissue-cells of beech tree Component of hardwood tissue Vessel 20% Wood fiber 60% Axial parenchyma cell 10% Radial parenchyma cell 10%

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

April 22, 2014

Biomaterial Science by Toshiharu Enomae 1

EG60411 Bio-Material ScienceToshiharu Enomae

Professor, PhD, Paper Device and Eco-friendly materials

2G103, 10:10-11:25, Tuesday

Biomaterial Science(Schedule)#### DateDateDateDate ContentContentContentContent

1 4/15 History of papermaking

2 4/22 Pulps – Beating and fiber properties

3 5/9, Fri Pulps – Additives and functions

4 5/13 Papermaking processes & interfiber bonding

5 5/20 Paper– Structural and absorption properties

6 5/27 Paper– Mechanical and optical properties

7 6/3 Polysaccharide chemistry by Assoc Prof Akiko Nakagawa

8-9 6/10, 17 Pulping science and technology by Professor Hiroshi Ohi

10 6/24 Recent trend of paper science and technology

Lecture information and contact

� Homepage of “Biomaterial Science (T. Enomae)”

� http://www.enomae.com/→ Handouts in lecture(講義資料)

� E-mail address→ [email protected] any questions and visit to laboratory (Bio-Agr. Bldg. 生農C209 or E201)

Production of paper and paperboard

0

20

40

60

80

100

120

1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012

China

USA

Japan

Germany

Sweden

Korea

Canada

Finland

Brazil

Indonesia

India

Thailand

Pro

duc

tion

, m

illio

n to

n

(A2)

(A3)

How to make paper � From “wood”

PaperChipPulp

Waste paperForest

Wood(thinned out)

(A4)

Wood tissue-cells of beech tree

Component of hardwood tissue

Vessel 20%

Wood fiber 60%

Axial parenchyma cell

10%

Radial parenchyma cell

10%

April 22, 2014

Biomaterial Science by Toshiharu Enomae 2

Axial parenchyma cell

0.1 mmparenchyma cells

Polarized light

Bast fibers

Bright-field

Wood tissue-structure of cell wall

(Secondary cell wall - 3rd layer )

S2 layerCellulose microfibril(indicated by parallel lines)

S3 layer

S1 layer

Middle lamellaPrimary wall

Structure of plant cell wall and axial direction of cellulose microfibrils

Kind of pulp

� Pulp� Fibers mainly consisting of cellulose

extracted from plant such as wood by mechanical or chemical treatment

� Mechanical pulp [MP]� Fibers extracted from wood by crushing

� Chemical pulp [CP]� Fibers extracted from wood by dissolving lignin

� Deinked pulp [DIP] (recycled pulp)� Fibers extracted from waste paper by removing ink

� Copy paperconsists of wood pulp fibers

Softwood pulp fiber Hardwood pulp fiber

Chemical pulp-Fiber geometry

(B)

� Observe pulps

Wood composition-Major 3 components

Chemicalcomponent

Approx. ratio (%)

Softwood Hardwood

Cellulose 45 45

Hemicellulose 25 30

Lignin 25 20

OthersTerpenoidResin acidFatty acidetc.

2 - 8Change of Composition

by kraft pulping

10 %

Lignin20 %

Others5 %

Hemi-cellulose30 %

HardwoodBleached kraft pulp

Cellulose45 %

40 %

2 %

Form of pulp

� Slush pulpPulp suspension with concentrations of approx. 1-4%

� Lap pulpPulp Formed and folded by wet machine. Called “Dry lap” when dried

� Bale pulpA bunch of pulp sheets compressed and bound with a wire

Transported pulp

Dry lap pulp

(C)

April 22, 2014

Biomaterial Science by Toshiharu Enomae 3

Dispersed in water

Dry lap pulp

Disintegration - Separation into individual fibers

( pulp)(D)

Standard disintegrator (defibrator)

� Pulp is put in water in steel container with ca. 3.4 L capacity

� Stirred with a propeller mixer at 3000 min-1

(rpm)

� Latency of MP should be removed at high temperature(Latent=hidden)

Pulp Dry mass

Water volume

Revol-utions

Chemical 30 g 2.0 L 30,000

Mechanical 60 g 2.7 L 60,000

Waste paper in yard Waste paper and pulp

Belt conveyer Disintegration in industry (pulper)

April 22, 2014

Biomaterial Science by Toshiharu Enomae 4

Disintegration in industry (Drum pulper)

Drum pulper

Floatation

� Bleaching � Deinking

Peroxidetower

Post-flowtator

Dis

pers

er

Centr

ifugal

Post-flowtation

Floatation (flowtator) Beating (refining)� Post-disintegration process

� Process where shear stress is applied to water-containing fibers resulting in fibrillation (formation of small filaments or fibers) on the surface and concentrically loose structure

Beating (refining)� Beating achieves large bonded area

between fibers and thus higher paper strength.

Q. Why can this breaking process increase paper strength?

Difference between disintegration and beating

� Disintegration is a process to separate fibers bonded or entangled, keeping fiber characteristics

� Beating is a process to treat mechanically individual fibers, changing fiber characteristics

April 22, 2014

Biomaterial Science by Toshiharu Enomae 5

Beater-Refiner(refining)

� Processed by refiner

RotorBlade

Stator

RotorStator

Disk plate

Pulp slurry flow

Motor

OutIn

Out

Beater-PFI mill (beating)

Beating - mechanism

Effect of blades on pulp fibers during beating

Refining-movie-refiner

Beating-change of fibers-external fibrillation

Scanning Electron Micrographs of freeze-dried softwood pulp fibers after beating

External fibrillation

Internal fibrillation

Beating-change of fibers-internal fibrillation

Lamellar separation of fiber cell wall by beating

=Concentric loosening (Lamellar separation)

Connection of small pores formed by lignin removal

External fibrillation

Internal fibrillation

Related Documents

![Toshiharu Furukawa, M.D., M.B.A., Ph.D....2020/03/27 · Toshiharu Furukawa, M.D., M.B.A., Ph.D. 1 Significant Scientific Evidences about COVID -19 [ 2020 年5月5日版] [ ]内は作成者の私的なコメントです。なお、特に記憶しておくべきと考えた所見を順に](https://static.cupdf.com/doc/110x72/5fbd50a9415a36626334e5b2/toshiharu-furukawa-md-mba-phd-20200327-toshiharu-furukawa-md.jpg)

![Yasaka, Toshiharu, Tiong, Sheena Y.X., Polgár, Erika ...eprints.gla.ac.uk/91268/1/91268.pdfperceived as itch [30]. Primary afferent input to the dorsal horn is arranged in a highly](https://static.cupdf.com/doc/110x72/5f0949a27e708231d4261b27/yasaka-toshiharu-tiong-sheena-yx-polgr-erika-perceived-as-itch-30.jpg)