2 Storage – Dosing Extraction – Transfer - Introduction More About Us FLOOR + OVERHEAD CONVEYING SYSTEMS SOLUTIONS FOR ALTERNATIVE SOLID FUELS 230 people / 40 M 230 people / 40 M € €

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

22

Storage – Dosing Extraction – Transfer - Introduction

More About Us

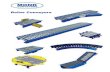

FLOOR + OVERHEAD CONVEYING SYSTEMS SOLUTIONS FOR ALTERNATIVE SOLID FUELS

230 people / 40 M 230 people / 40 M €€

33

ATS IndiaATS India (PUNE)

Storage – Dosing Extraction – Transfer - Introduction

Located in Pune

Started in January 2005

100% subsidiary of ATS group

Mechanical and Automation Concepts from Europe

Critical items from Europe

Fabrication & Assembly in India

Assembly and test Workshop

Manufacturing Workshop18,000 sq.ft.

About us

Storage – Dosing Extraction – Transfer - Introduction

Use of alternative fuels

CALCINER(ASF coarse)

MAIN BURNER(ASF fine)

KILN INLET(ASF coarse)

55

Grain size 1 to 500 mmGrain size 1 to 500 mm

Density 0,1 to 1,2Density 0,1 to 1,2

Impregnated sawdustImpregnated sawdust Cashewnuts shellsCashewnuts shells Wood piecesWood pieces FluffFluff

Shredded tyresShredded tyres Coconuts husksCoconuts husks Car LampsCar Lamps Whole tyresWhole tyres

Storage – Dosing Extraction – Transfer - Introduction

Solid fuels examples

77

Whole tyre system

Holcim

- Clinker production: 750 000T/year

- Cement production: 1 000 000 T/year

- Founded in 1977

- Precursor in the use of ASF in Spain since 1990

88

Whole tyre system

ASF use on main burner side

Using of different ASF since 1990

- Sawdust

- Solvant, oilSubstitution rate: 13%

Sawdust

Solvant

99

Whole tyre system

Customer request

• Diameter 600 to 1200mm

• No Rim

• Individual Tyres sizes control

• Calorific value: 6500 kcalorie/kg

• Controlled flow rate

Decision to use whole tyres

Increasing of the substitution rate

1010

Whole tyre system

Whole tyres introduction

• Introduction point: Kiln inlet

• Tyres rolling behavior during the introduction

Kiln inlet

1111

Whole tyre system

Solution 1: Hook elevator

• Compact design

• Tyres diameter: 600mm to 1250mm

• Capacity: 300 Tyres/hour

1212

Whole tyre system Holcim Spain

1. Moving floor

2. Singulator

3. Roller conveyor

4. Tyre size control conveyor

5. Reversible conveyor

6. Accumulator conveyors

7. Dosing conveyor

8. Transfer belt conveyors

9. Double valve air lock

Solution 2: Singulator + belt conveyor

1313

Whole tyre system: Holcim Spain

Moving floor

Capacity: 100m3

Loading with front loader

Moving floor

Singulator

1414

Whole tyre system

Singulator

Flow rate: 700 tyres/hour

Loading directly from moving floor

Chute Disc

Hopper

Loads cells

1515

Whole tyre system

Tyres control conv.

Dosing conv.

Reversible conv.

Concept

1616

Whole tyre system

• Diameter control: 600mm min 1200 max

• Height control: 400 mm max

• Rim detection (metal detection)

Cells

Tyres control conveyor

1717

Whole tyre system

Accumulator conveyor

Dosing unit

Accumulator conv.

1818

Whole tyre system

Dosing roller conveyor

Loads cells

1919

Whole tyre system

Main transfer

•Chevron belt conveyor

•Width: 1400 mm

•Length: 88m

•Angle: 28°

Transfer in the tower

• Flat belt conveyor

•Width: 1400 mm

•Length: 6m

Transfer systems

2020

Security, liabilitySecurity, liability

Upper valve

Bottom valve

Sliding gate

Expantion joint

Whole tyre system

Pneumatic double valve airlock

2121

Whole tyre system

Pneumatic Double Valve Airlock

2222

Whole tyre system

Tyres introduction one by one by rolling into the kiln

Introduction in the kiln inlet

2323

Whole tyre system

• Holcim used 5500T Whole tyres in 2009 (*)

• Whole tyres calorific value in 2009 = 4300T Pet co ke

• Increase of the substitution rate more than +10%

• Total substitution rate with all ASF = 25%

* Considering that the plant run to 70% of its capaci ty in 2009

Conclusion

2424

Shredded tyres system

Lafarge

2525

Shredded tyres system

Lafarge

Decision to use shredded tyres

• grain size: 50x50 mm

• Introduction into the calciner: line 1 and line 2

• Controlled flow rate : 5T/h for each line

2626

Shredded tyres system

Automated crane system

• Monorail crane: 5 T

• Grab: 2,5m3

2727

Shredded tyres system

Dosing extractor

Integrated dosing system Integrated dosing system using weight cellsusing weight cells

2828

Shredded tyres system

Dosing system

A A controlledcontrolled constant flow!constant flow!

D

A

M3~

REG

+

-

APRON FEEDER

SPEED CONTROLLER

HOPPER

LOAD CELLS

~

~

APRON FEEDER

DOSING

SYSTEM

AF

FLOW SET POINT

t

PQ tm ∆

∆=•

)( with

( )ρ,,)( sLKVQ extrtm •=•

ρ×××∆=∆ sLlP

2929

Shredded tyres system

Loading and dosing

3030

Shredded tyres system

Double valve airlock

• cross section: 650x650

• flow rate: 100m3/h

• grain size max: 300 mm

Bottom valve

Sliding gate

Expansion joint

3131

Implantation DrawingItalcementi India: Biomass system

Rice Husk:Zuari cement

FLEXIBEL SYSTEMS !

Grain size: 1 to 500mm

Density: 0,1 to 1,5T/m3

Biomass system

Belt conveyors: Zuari Cement

Biomass system

• 3 flat belt conveyors

• enclosed design

•Total lenght 340 m

=> 8T/h (Rice Husk)

3434

Biomass system

Electrical double valve air lock

3535

• Reduced cycle time: 6sec

• High secured : :

• Counter weight for the valves

• Air tank for the sliding gate

Single flap

Drive motor

Counter weight

Electrical double valve air lockBiosmass system

3636

Running principStorage – Dosing Extraction – Transfer – Feeding system

3737

3 security levels

Level 1

Level 2

Level 3

Temperature sensor

Biomass system

3838

World ActionsStorage – Dosing Extraction – Transfer - Introduction

3939

Your contacts :Your contacts :

Luc RieffelLuc Rieffel D.V. TambeD.V. Tambe

+33 620 83 73 53+33 620 83 73 53 +91 9922 00 7142+91 9922 00 7142

[email protected]@appalette.com [email protected]@atsconveyors.com

4040

Related Documents