Iron Ore and Steel

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

A.) Mining Iron Ore

1.) Drill and blast

Hematite (Fe203)

Magnetite (Fe304)

2.) Shovel into a truck and bring to mill

3.) Crush into a powder

4.) Add clay and roll into balls, harden in kiln

5.) Ship to steel mill

B.) Making Pig Iron from Iron Ore

1.) Melt Iron Ore in a Blast Furnace with Limestone and coke.

2.) Coke is almost pure carbon made from coal.

3.) Limestone is a flux, it helps remove impurities such as sand from the iron.

4.) Blowing hot air (11000F) past the coke causes a reaction that creates high enough temperatures (30000F) to melt the iron.

C.) Making Steel from Pig Iron

1.) heating pig iron (4%C) in a Converter burns off Carbon to 2% or less.

a.) Electric Arc Furnace

b.) Oxygen Lance Furnace

2.) scrap steel and alloying elements are added to the pot .

3.) test steel composition.

4.) steel is cast into ingots or or continuous pours.

Basic Oxygen Steelmaking Plant showing scrap being charged into the BOF vessel. A ladle full of hot metal is seen to the right. John Stubbles photo

C.) Making Steel from Pig Iron

A ladle of molten steel leaving for the ladle metallurgical facility or the caster. John Stubbles photo

BOF Vessel in Its Operating Positions

BOF Vessel in Its Operating Positions. (Ref: Making, Shaping, and Treating of Steel, 11th Edition, Steelmaking And Refining Volume. AISE Steel Foundation, 1998, Pittsburgh PA)

1.1. 2.

3. 4.

5. 6.

C.) Making Steel from Pig Iron

Section through the BOF vessel during oxygen blowing. (Ref: Making, Shaping, and Treating of Steel, 11th Edition, Steelmaking And Refining Volume. AISE Steel Foundation, 1998, Pittsburgh PA)

C.) Making Steel from Pig Iron

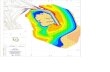

Figure from AISI website: http://www.steel.org/learning/flowline/index.htm

C.) Making Steel from Pig Iron - Electric Arc Furnace

Figure by Jeremy A. T. Jones, Nupro Corporation

D.) Rolling Mill1.) Slabs are rolled into sheets (<1/4”)or plates (>1/4”).2.) Blooms are made into Billets.3.) Billets are rolled into bars and

shapes.4.) Bars can be drawn into wire.5.) Effects of rolling.

a.) Anisotropic properties.b.) Cold rolling hardens steel more than hot rolling.

G.) References1.) AISI Website http://www.steel.org/learning

2.) John A. Ricketts, Ispat Inland, Inc.

3.) John Stubbles, Steel Industry Consultant

4.) By Jeremy A. T. Jones, Nupro Corporation

A.) Gray Cast Iron

1.) Composition (in addition to Fe):4% Carbon (+) in the form of graphite

flakes that form tiny cracks. 1-3% Silicon (Si) Trace amounts of Mn and P

B.) White Cast Iron

1.) Composition (in addition to Fe):2.5-3.5% Carbon (+) C in combined form

(iron carbide) 1-3% Silicon (Si)

2.)Classified byu, y, and %LExample/ 60:40:18

3.) Advantageshard (BHN > 400) - good wear resistance

( grinding mills etc.) good dampinghigh compressive strength ( 200,000 psi)

B.) White Cast Iron

C.) Ductile Iron

1.) Composition: Carbon is in nodular (round) form instead of free flakes or iron carbide):

2.5-3.5% Carbon (+) 0.80% Mn 1.8-2.8% Si

2.)Classified byu, y, and %L Example/ 60:40:18

Related Documents