30°& 45°Angle Bay Window Assembly and Installation Guide for Andersen ® 400 Series Tilt-Wash and 200 Series Narroline ® Double-Hung Windows Instructions are for typical, new wood-framed wall construction with weather protection in place. Instructions may not be right for all installations due to building design, construction materials or methods used and/or building or site conditions. Consult a contractor or architect for recommendations. Flanges on the unit alone will not properly flash and seal the window. Follow these instructions carefully. For questions call 1-888-888-7020 Monday - Friday, 7 a.m. to 7 p.m. and Saturday, 8 a.m. to 4 p.m. central time. For more information and/or guides visit andersenwindows.com. Please leave this guide with building owner. Thank you for choosing Andersen. ▶ ▶ Read▶guide▶from▶beginning▶to▶end▶before▶starting▶installation.▶Read▶all▶warnings▶and▶cautions▶during▶unit▶installation.▶▶ Use caution when working at elevated heights and around unit openings. Follow manufacturers’ instructions for ladders and/or scaffolding. Failure to do so may result in injury or death. Follow manufacturers’ instructions for hand or power tools. Always wear safety glasses. Failure to do so may result in injury and/or product damage. Windows and doors can be heavy. Use safe lifting techniques and a reasonable number of people with enough strength to lift, carry and install window and door products to avoid injury and/or product damage. “Andersen” and all other marks where denoted are trademarks of Andersen Corporation. ©1996-2010 Andersen Corporation. All rights reserved. 0005133 BD Revised 10/27/10 Unless specifically ordered, Andersen windows and doors are not equipped with safety glass, and if broken, could fragment causing injury. Many laws and building codes require safety glass in locations adjacent to or near doors. Andersen windows are available with safety glass that may reduce the likelihood of injury when broken. Information on safety glass is available from your local Andersen dealer. • Andersen ® Head Flashing and Installation Flanges DO NOT take the place of standard window and door flashing. Unit must be properly flashed and sealed with sealant for protection against water and air infiltration. Use non-reflective flashings. Highly reflective flashing tapes can raise the surface temperature of the vinyl to the point where vinyl deformation and product damage may occur. • Do not apply any type of film to glass. Thermal stress conditions resulting in glass damage could occur. • Use of movable insulating materials such as window coverings, shutters, and other shading devices may damage glass and/or vinyl. In addition, excessive condensation may result causing deterioration of windows and doors.

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

30°& 45°Angle Bay Window Assembly and Installation Guidefor Andersen® 400 Series Tilt-Wash and 200 Series Narroline® Double-Hung Windows

Instructions are for typical, new wood-framed wall construction with weather protection in place.

Instructions may not be right for all installations due to building design, construction materials or methods used and/or building or site conditions. Consult a contractor or architect for recommendations.

Flanges on the unit alone will not properly flash and seal the window. Follow these instructions carefully.

For questions call 1-888-888-7020 Monday - Friday, 7 a.m. to 7 p.m. and Saturday, 8 a.m. to 4 p.m. central time.

For more information and/or guides visit andersenwindows.com.

Please leave this guide with building owner.

Thank you for choosing Andersen.

▶▶ Read▶guide▶from▶beginning▶to▶end▶before▶starting▶installation.▶Read▶all▶warnings▶and▶cautions▶during▶unit▶installation.▶▶

Use caution when working at elevated heights and around unit openings. Follow manufacturers’ instructions for ladders and/or scaffolding. Failure to do so may result in injury or death.

Follow manufacturers’ instructions for hand or power tools. Always wear safety glasses. Failure to do so may result in injury and/or product damage.

Windows and doors can be heavy. Use safe lifting techniques and a reasonable number of people with enough strength to lift, carry and install window and door products to avoid injury and/or product damage.

“Andersen” and all other marks where denoted are trademarks of Andersen Corporation. ©1996-2010 Andersen Corporation. All rights reser ved. 0005133 BD Revised 10/27/10

Unless specifically ordered, Andersen windows and doors are not equipped with safety glass, and if broken, could fragment causing injury. Many laws and building codes require safety glass in locations adjacent to or near doors. Andersen windows are available with safety glass that may reduce the likelihood of injury when broken. Information on safety glass is available from your local Andersen dealer.

• Andersen® Head Flashing and Installation Flanges DO NOT take the place of standard window and door flashing. Unit must be properly flashed and sealed with sealant for protection against water and air infiltration. Use non-reflective flashings. Highly reflective flashing tapes can raise the surface temperature of the vinyl to the point where vinyl deformation and product damage may occur.

• Do not apply any type of film to glass. Thermal stress conditions resulting in glass damage could occur.

• Use of movable insulating materials such as window coverings, shutters, and other shading devices may damage glass and/or vinyl. In addition, excessive condensation may result causing deterioration of windows and doors.

Section One - 30° & 45° Bay Window Assembly Guide

2

For Joined Transom & 2-Wide Center Units OnlyInstallations with Joined Transom and/or 2-Wide Center Units require the use of additional joining material to join units. Refer to Combination Design Section of the Andersen® Product Guide for Professionals to make sure correct joining material is used and combination will appropriately perform and comply with local building codes. Consult an architect or contractor. Failure to do so could result in injury and/or product damage.

Parts Required• Center Unit(s) (A)• Flanking Units (B)• 30° or 45° Joining Posts (C)• Upper and Lower Platform (D)• Head and Seat Boards (E)• Joining Post Clips (F)• Joining Clips (G)• 30° or 45° Inside Joining Post Casing (H)• Side Flashing (I)• 30°or 45° Adaptor (J)• Rigid Foam Insulation (K)

Tools and Supplies• Safety Glasses• Hammer• Flat Blade Screwdriver• Phillips Screwdriver • Level• Carpenter’s Square• Combination Square• Tape Measure• Clamps• Shims (waterproof) • Caulk Gun• Sealant• Flashing Tape• Pencil• Small Pry Bar• Awl• Sharp Utility Knife• Soft Rags• Isopropyl Alcohol• Jack and Support• Flat Head Wood Screws #8 x 1-1/4" #8 x 1-1/2" #8 x 2" #8 x 2-1/2" #8 x 3" #8 x 5-1/2"• Drill/Driver• 3/8" Drill Bit• 1/8" Drill Bit• 3/32" Drill Bit• 1-1/4" Finishing Nails• 2-1/2" Finishing Nails• 3/4" Staples or Nails• 1-3/8" Spacer Boards• 2 x 4 Skid Material• 1 x 4 Cross Bracing

Component Identification

Optional Accessories• Extension Jambs (L)• Head and Seat Board Inside Trim• Auxiliary Casing• Cable Support System• Perma-Shield® Narroline® Sill Stop• Fibrex® Cellular Trim Board

Interior Side Up

Section One - 30° & 45° Bay Window Assembly

L

J

I

B

C

D

K

HA

E K

H

FG C

B

L

I

J

Metal fasteners and other hardware components may corrode when exposed to preservative treated and fire-retardant treated lumber. Obtain and use the appropriate metal fasteners and hardware as called out by the installation guide to fasten unit to any rough opening made from pressure treated and fire-retardant treated lumber. Failure to use the appropriate materials for the installation may cause a failure resulting in injury, property or product damage.

Section One - 30° & 45° Bay Window Assembly Guide

3

For Joined Transom Units Only• Transom joining of units must be

performed before bay unit assembly begins. Perform transom joining according to instructions in the Double-Hung Transom Joining Kit.

• Projecting Units with Transom Units attached must not exceed 8' 2-1/4" in height.

For Joined Transom & 2-Wide Center Units Only• Determine joining type required according to Combination Design Section of the Andersen® Product Guide for

Professionals.• Determine unit windload performance capacity. Join units according to appropriate design windload table

found in the Andersen® Product Guide for Professionals.• Join units according to appropriate joining material kit's instruction guide. • Available joining material kits include Non Reinforced Joining Kit for Tilt-Wash Units, Non Reinforced Joining Kit

for Narroline® Units, and Non Reinforced Joining with Transom Attached Kit.

For 2-Wide Center Units Only• Center units must be joined before

proceeding with bay unit assembly. • Follow joining instructions when two

Tilt-Wash or two Narroline® Windows are used in place of a Double-Hung Picture Window.

Section One - 30° & 45° Bay Window Assembly Guide

4

Attach Head Filler Piece to head of Tilt-Wash and Double-Hung Picture Window Units flush with Head Jamb using 1" staples or nails located every 6" (staples or nails are not included in kit).

Head Filler Piece

Double-Hung Picture Window or Tilt-Wash Unit Only

Head Jamb

1" Staple or Nail

For Tilt-Wash and Double-Hung Picture Units Only

Interior Side Up

1. Prepare Units for Assembly

• When arranging units for assembly, make sure placement and direction of units are correct.

• Wall must be 4-9/16" to 7-1/8" for stock platforms, head boards, and seat boards.

HeadCenter Unit(s) Flanking UnitFlanking Unit

Sill

• Carefully remove units from cartons and place interior side up on a clean flat work surface.

• Remove foam packing blocks.• Remove Side Installation Flanges by pulling outward

from sides on all units.• Trim Head and Sill Installation Flange flush with Side

Jambs of units using a sharp utility knife. • Arrange units in correct positions for assembly.

Trim Head Installation Flanges Flush with Side Jambs

Remove Side Installation Flanges

Interior Side Up

Side Jamb

Trim Sill Installation Flanges Flush with Side Jamb

2. Attach Flanking Units to Center Unit(s)• Slide units together aligning head and sill

of Flanking Units with Center Unit(s).

Center Unit(s) Flanking UnitFlanking UnitInterior Side Up

Section One - 30° & 45° Bay Window Assembly Guide

5

2. Attach Flanking Units to Center Unit(s) (Continued)

Double-Hung Picture Window to Narroline®

Double-Hung WindowTilt-Wash to Tilt-Wash

Tilt-Wash to Double-Hung Picture Window Narroline® to Narroline Double-Hung Window

Tilt-Wash Joining Clip

Narroline® Joining Clip

• Position Joining Clips on side jambs 4" from ends of units. Equally space remaining two clips on units. For Joined Transom Units, an extra set of Joining Clips are needed.

• Tap Joining Clips into place. Predrill through holes 1-1/4" deep, using a 3/32" drill bit, and fasten Joining Clips using #8 x 1-1/4" screws.

Joining Clip

For Narroline® Flanking Units OnlyPlace temporary shims under outside edge of Flanking Units until Joining Clips are fastened.

Interior Side Up

• Determine type of Joining Clip to apply according to units being joined from details below.

• Place Platforms rough side up on work surface. • Measure length of Platform along interior edge. Place

pencil mark at center of Platform.• Mark centerline across width of Platform using

carpenter’s square.• Repeat step for other Platform.

• Flip Upper Platform over, smooth side up (opposite side of centerline mark).

• Scribe two lines, 3" and 1-1/4" in from and along entire length of exterior edge of Upper Platform using combination square.

3. Prepare Platforms

1-1/4" Scribed Line

3" Scribed Line

Centerline Mark

Upper Platform

Upper Platform

Combination Square

Carpenter’s Square

Pencil

Narroline® Joining Clip

Upper/Lower Platform

Rough Side

Smooth Side

Interior Edge

Exterior Edge

Section One - 30° & 45° Bay Window Assembly Guide

6

4. Determine and Mark Centerline on Unit

• For Single Center Unit, measure width of center unit along frame. Place pencil mark at center of unit on frame, as shown. Repeat at other end of center unit.

• For 2-Wide Center Unit, place pencil mark in center of middle Joining Post or joining area. Repeat at other end of middle Joining Post.

Mark Center

Single Center Unit

5. Position and Temporarily Secure Lower Platform

• Position Lower Platform, centerline facing inward, against Installation Flange of Center Unit(s).

• Align centerline on Lower Platform with center mark on Center Unit(s).

• Drill 3/32" holes every 4"- 6" on scribe line no more than 1-1/2" deep.

• Temporarily fasten Lower Platform using two #8 x 1-1/2" flat head wood screws placed on scribed line.

Sill

Head

Lower Platform

Installation Flange

Number of center units will determine centerline placement on unit. Follow procedure below according to number of center units in installation.

For Narroline® Center Units OnlyNarroline Units have a flexible weatherstrip on Sill in place of a rigid Installation Flange. Lower Platform, when positioned, cannot rest on flexible weatherstrip. Use a 1-3/8" thick spacer under flexible weatherstrip to help support Lower Platform.

Interior Side Up

Interior Side Up

Pencil

• Flip Lower Platform over, smooth side up (opposite side of centerline mark).

• Scribe a line 3/4" in from and along entire length of exterior edge of Lower Platform using combination square.

Lower Platform

3. Prepare Platforms (Continued)

Lower Platform

3/4" Scribed LineCombination Square

Sill

Pencil

Head

Smooth Side

Smooth Side

Section One - 30° & 45° Bay Window Assembly Guide

7

6. Secure Lower Platform to Center Unit(s)• Fasten Lower Platform to center unit(s) along scribed

line using #8 x 1-1/2" flat head wood screws in predrilled holes.

Lower Platform

#8 x 1-1/2" Screw

Scribed Line

Lower Platform

SillInterior Side Up

4" to 6"

3/4"Cross Section Detail

• Fasten Upper Platform to center unit(s) along scribed lines, as shown, using #8 x 1-1/2" flat head wood screws. Space screws at 6" to 8" intervals.

Head

Sill

Upper Platform

#8 x 1-1/2" Screw

7. Secure Upper Platform to Center Unit(s)

Upper Platform

DO NOT place screws in balancer areas highlighted in black.

FlankingUnit

FlankingUnit

DO NOT place screws in balancer areas highlighted in black.

For Narroline® Double-Hung Windows OnlyDO NOT secure Upper Platform to head of Narroline® Units within 8" of either side jamb. Balancer damage will result.

Interior Side UpScribed Lines

6" to 8"

3"

1-1/4"

Cross Section Detail

Double-Hung Picture Window as Center Unit

Narroline Unit(s) as Center Unit

FlankingUnit

FlankingUnit

8"

8" 8"

8"

8"

8" 8"

8"

8" 8" 8" 8"

Section One - 30° & 45° Bay Window Assembly Guide

8

9. Secure Platforms to Flanking Units

Flanking Unit Flanking UnitHead

Upper Platform

Upper Platform

For Narroline® Double-Hung Windows OnlyDO NOT secure Upper Platform to head of Narroline® Units within 8" of either side jamb. Balancer damage will result. Refer to caution in Step 7 for balancer locations.

• Lift Flanking Unit into position and temporarily secure to Upper Platform using a 1-1/2" flat head wood screw. Place screw on scribed lines of Upper Platform.

• Repeat procedure for Lower Platform.• Repeat procedure for opposite Flanking Unit.• Check Head and Seat Board for correct fit.

If adjustment is needed, remove temporary screw and readjust unit to obtain correct fit. Reattach Flanking Unit using 1-1/2" flat head wood screw in a different location than above.

• Fasten Upper Platform to head of Flanking Units using 1-1/2" flat head wood screws. Locate screws along scribed lines 1-1/4" and 3" in from the exterior edge of Upper Platform. Space screws at 6" to 8" intervals.

• Fasten Lower Platform to sill of Flanking Units using 1-1/2" flat head wood screws. Locate screws along scribed lines 3/4" in from the exterior edge of Lower Platform. Space screws at 6" to 8" intervals.

Interior Side Up

Scribed Lines

8. Position Head and Seat Boards Temporarily

• Determine interior finished side of Head and Seat Boards.

• Place Head Board, finished toward interior, into position against Upper Platform.

• Place Seat Board, finished toward interior, into position against Lower Platform.

• Place a 1-1/2" thick spacer board between Lower Platform and Seat Board.

• Center Head and Seat Board to obtain best fit. • Clamp Head and Seat Board to Platforms.

Head Board(unfinished side)

Head

Clamp

Upper Platform

Head and Seat Boards must be temporarily installed as a template to assist in securing Platforms.

Interior Side Up

Seat Board(finished side)

Lower Platform

1-1/2" Spacer Board Head Board

(installed)

Sill

Head

1-1/2" Flat Head Screws

Note: Upper Platform shown in illustrations.

Seat Board (installed)

Section One - 30° & 45° Bay Window Assembly Guide

9

3"1-1/4"

2-3/16"2-3

/16"

1-1/4"3"

Head

10. Secure Platforms to Side Jambs• Determine screw locations for securing Platforms to

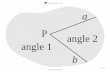

Side Jambs using either 30° Joining Post or 45° Joining Post detail below.

• Mark screw positions by measuring along edge of Platforms from corner at Joining Post. Locate screws 1-1/4" and 3" in from exterior edge of Platforms.

• Fasten Platforms to Side Jambs of Center and Flanking Units using #8 x 1-1/2" flat head wood screws.

• Repeat procedure for sill end of unit.

Area of cross section details to left.

For Custom Bay Using Cable Support System OnlyPlatforms and Head/Seat Boards for Custom Bay Units may not have predrilled holes for Cable Support System. Follow Cable Hole Template instructions, found in the Cable Support System Package, to determine cable hole locations. Drill 3/8" holes through Platforms and Head/Seat Boards at all Joining Post locations before proceeding with Step 11.

Cross Section Detail30° Mullion Post

Cross Section Detail45° Mullion Post Interior Side Up

12. Apply Skids and Cross Bracing• Cut and fasten, using #8 x 2" screws, two 2 x 4 skids to

Lower Platform for transporting unit. Make sure skid closest to interior is at least 5" from interior edge of Lower Platform.

• Fasten 1 x 4 cross brace to corners of platforms at a diagonal, as shown, using screws.

1 x 4 Cross Brace

2 x 4 Skids

• Label Head Board and Seat Boards for reinstallation.• Remove clamps holding Head Board and Seat Board to

Platforms. • Carefully remove and repackage Head Board and Seat

Board for shipment to installation site.

11. Remove Head and Seat Boards Seat Board ClampsHead Board

Upper Platform

Interior Side Up

Interior Side Up

Head

Sill

5"

1 x 4 Cross Brace

Lower Platform Sill

3"1-1/4"

1-9/16" 1-9/16"

1-1/4"3"

Head

Sill

Section One - 30° & 45° Bay Window Assembly Guide

10

14. Cut Head End of Joining Post (Joined Transom Units Only)

• Measure height from sill of bottom unit to head of Transom Unit.

• Measure Joining Post beginning at sill end and mark location of cut on head end using a pencil. Sill end has a step cut. DO NOT cut off sill end.

• Cut off head end of Joining Post squarely at pencil mark.

15. Apply Joining Post Clips• Position Joining Post Clips in side jamb kerf 4" from

Joining Post ends. Space remaining Joining Post Clips equally along Joining Post.

• Fasten Joining Post Clips using #8 x 1-1/4" flat head screws.

Joining Post Clip

Joining Post

Sill End With Step Cut

Head End

Cut and Remove Head End

Pencil Mark

• Carefully flip unit over exterior side up. • Insert rigid foam insulation into Joining Post area.• Seal entire edge of rigid foam insulation to units and

Platforms using 1/4" bead of sealant.

13. Apply Rigid Foam Insulation

Rigid FoamInsulation Installed

Note: Platform omitted for clarity.

Apply Sealant Along Edge

Joined Transom Bay Units OnlyJoining Posts for Joined Transom Bay Units must be measured and cut to size.

Joined Transom Bay Units OnlyPlace an additional two Joining Post Clips in side jamb kerf 2" from ends of Transom Units.

Windows and doors can be heavy. Use safe lifting techniques and a reasonable number of people with enough strength to lift, carry and install window and door products to avoid injury and/or product damage.

Exterior Side Up

Joining Post

Joining Post Clip

#8 x 1-1/4" Flat Head Screw

Section One - 30° & 45° Bay Window Assembly Guide

11

17. Seal Ends of Joining Posts Apply Sealant to Ends of JoiningPost

Sill

16. Install Joining Posts • Position 30° or 45° Joining Posts with square

end flush with head of unit.

• Beginning at one end, gently tap Joining Posts into place using a hammer and wood block.

30° or 45° Joining Post

FlankingUnit

Center Unit(s)

DO NOT tap on ridge in center of Joining Post. Tapping on ridge could result in damage to Joining Post.

18. Apply Auxiliary Casing

• Measure and cut Auxiliary Casing to fit along head of unit. For 45° Bay Units, cut 22-1/2° miters. For 30° Bay Units cut 15° miters.

• For Flanking Units, cut outermost ends of Auxiliary Casing flush with outside edge of Flanking Unit and parallel to edge of Platform as shown.

• Position and hold Auxiliary Casing in place. Predrill through insect screen slot in Head Outer Frame Member using a 3/32" drill bit, 1-1/4" deep. Space holes every 6" to 8".

• Apply sealant between Platform and units and at all mitered ends of Auxiliary Casing.

• Fasten Auxiliary Casing through predrilled holes using corrosion resistant 1-1/2" flat head wood screws.

• Remove any excess sealant squeeze out on units or Auxiliary Casing using a soft rag.

Auxiliary Casing

Head

Sill

Head

Auxiliary Casing

Cross Section Detail - Vertical

Corrosion Resistant 1-1/2" Screw

Head Outer Frame Member

Insect Screen Slot

Cut Auxiliary Casing flush with edge of Flanking Unit and parallel with edge of platform.

Upper Platform

SealantSealant

Sealant

DO NOT overtighten screws. Overtightening screws may cause damage to Head Outer Frame Members.

Exterior Side Up

• Clean exterior surface of unit at head and sill ends of Joining Posts using isopropyl alcohol and a clean cloth.

• Seal head and sill ends of Joining Posts using sealant. Level out sealant using a small piece of cardboard.

Head

Note: Platform omitted for clarity.

Exterior Side Up

Apply Sealant to Ends of JoiningPost

Section One - 30° & 45° Bay Window Assembly Guide

12

20. Secure Joining Posts

Joining Clip

#10 x 5-1/2" Screw

21. Prepare Unit for Transport• Make sure all components and accessories are located

and prepared for transport to installation site along with unit. These may include the following:

- Interior 30° or 45° Joining Post Casing - Head and Seat Board Trim - Extension Jambs - Cable Support System - Head and Seat Boards - 3-1/2" Fibrex® Cellular Trim Board• For unit installation, proceed to Section 2 - 30° and 45°

Bay Window Installation on Page 13 of this guide.

• Carefully tighten screws until Joining Posts are snug up to outside of units.

• Carefully stand unit upright on sill end. Temporarily secure unit to flat or other stable surface using fasteners, straps, or 2 x 4 bracing.

19. Stand Unit Up and Secure

• Insert #10 x 5-1/2" long screw into all Joining Clips. Drive screw through rigid foam insulation and into Joining Posts until snug.

Flat

Rigid Foam Insulation

Please attach this assembly and installation

guide to glass of unit using a piece of tape.

ATTENTION DEALER / DISTRIBUTOR

Joining Post

Windows and doors can be heavy. Use safe lifting techniques and a reasonable number of people with enough strength to lift, carry and install window and door products to avoid injury and/or product damage.

30° or 45° Bay Window Unit must be supported at all times when in upright position to prevent tipping. Failure to do so could result in personal injury and product damage.

DO NOT overtighten screws. Overtightening screws will damage screws and/or Joining Posts.

Exterior View

Section Two - 30° & 45° Bay Window Installation Guide

13

1. Identify Type of Installation

• Most common type of installation.

• Used if rough opening height is smaller than Bay Unit.

• If window must be raised above previously installed header to meet soffit or to match line of adjoining window trim, cut top platform back to clear header as shown.

• If window is raised install filler blocks at sill plate of equal dimension to amount raised.

• Unit opening is extended down to floor line.

• Masonry anchoring required.

Section Two - 30° & 45° Bay Window Installation

Center Unit

Cable

Cable EndLower Platform

Upper Platform

Header

Cable Clamp

Shim

Double Sill Plate

Center Unit

Cable

Cable EndLower Platform

Upper Platform

Header

Cable Clamp

Double Sill Plate

Center Unit

Lower Platform cut back to wall thickness

Header

Shim

Double Sill Plate

Center Unit

Cable

Cable End Lower Platform

Upper Platform

Masonry

Cable Clamp

Shim/Nailer

Masonry

Shim/Nailer

Standard Installation

Modified Standard Installation

Walk-Out Installation

Masonry Installation

Metal fasteners and other hardware components may corrode when exposed to preservative treated and fire-retardant treated lumber. Obtain and use the appropriate metal fasteners and hardware as called out by the installation guide to fasten unit to any rough opening made from pressure treated and fire-retardant treated lumber. Failure to use the appropriate materials for the installation may cause a failure resulting in injury, property or product damage.

3-1/2" Fibrex® Cellular Trim Board or wider trim by others

3-1/2" Fibrex® Cellular Trim Board or wider trim by others

3-1/2" Fibrex® Cellular Trim Board or wider trim by others

3-1/2" Fibrex® Cellular Trim Board or wider trim by others

3-1/2" Fibrex® Cellular Trim Board or wider trim by others

3-1/2" Fibrex® Cellular Trim Board or wider trim by others

3-1/2" Fibrex® Cellular Trim Board or wider trim by others

Section Two - 30° & 45° Bay Window Installation Guide

14

2. Determine Type of Support System Required

Note: Units are omitted for clarity in all illustrations.

Posts Foundation

Header

Soffit

CableSupportSystem

Knee Braces

Knee Braces

• A support system such as a cable support system, post and foundation support, knee braces, and attachment to header or soffit support must be installed to properly support projecting window units. Failure to do so could result in product damage and/or incorrect operation of units.

• When a roof or bonnet is built over unit, make sure that adequate support is provided to carry weight of roof. Failure to do so could result in product damage and/or incorrect operation of units.

• If Custom Bay Unit is being installed, use Cable Support System at every Joining Post. Failure to do so could result in product damage and/or incorrect operation of units.

• Bay unit is supported by cables attached to header, gable or eave. Cable Support System allows unit to be adjusted to overcome difficulties associated with normal building settlement. The Cable Support System in 9' and 12' versions are available through your Andersen dealer. See Cable Support System Installation Guide for proper installation.

• IMPORTANT: If Custom Bay Unit is being installed, use Cable Support System at every Joining Post.

• Install Cable Support System after Step 7 on Page 16.

• When adequate support cannot be achieved by Cable Support System or by header or soffit support or cantilever system, Knee Braces (provided by others) must be attached to structural member below each Joining Post.

• Anchor Knee Brace into structural member or install double cripple below unit and secure braces into them.

• IMPORTANT: If Custom Bay Unit is being installed, use Cable Support System at every Joining Post.

• Bay unit is supported by cantilevered floor joist or attached directly to header/soffit. Projection of cantilevered floor joist must not exceed 1/3 of overall length of support joist.

• Unit is supported by post or foundation of dwelling.

Cable Support System Knee Brace

Cantilever Mount or Header/Soffit Post or Foundation Support

Exterior View Exterior Views

Exterior Views Exterior Views

1/3

2/3

Section Two - 30° & 45° Bay Window Installation Guide

15

Overall Wall Thickness

3. Prepare Rough Opening

• Frame rough opening to dimensions recommended at www.andersenwindows.com or prepare an existing rough opening. Masonry rough opening must be 1/2" greater than unit width and height.

• Make sure sill plate is level by checking with a level. Shim sill plate to level.

• Make sure rough opening is plumb by checking with a level.

• Make sure rough opening is square by placing tape measure diagonally across rough opening, upper left to lower right and upper right to lower left corner, if measurements are within 1/8", opening is square.

Level

Double Sill Plate

• Determine overall wall thickness (excluding siding) by measuring wall from outside edge of exterior sheathing to inside edge of interior wall board.

• Determine interior offset dimension by subtracting 4" from wall thickness dimension.

4. Determine Wall Thickness and Position of Unit in Wall

Interior Wallboard

Exterior Sheathing• From the interior, use a combination square to transfer

Interior Offset Dimension to double sill plate and header.

Acid solutions commonly used to wash masonry will damage glass, fasteners, hardware, and metal flashings. Follow the cleaning solution manufacturer's recommendations carefully. Protect and/or cover Andersen products during cleaning process to prevent acid contact. If solution does come in contact with unit immediately wash all surfaces with clean water.

Pencil

Interior View

Formula: Overall Wall - 4" = Interior Offset Dimension Dimension

Example: 6-9/16" - 4" = 2-9/16"

Interior Offset Dimension

Overall Wall Thickness

4"

Rough Opening Width

RoughOpeningHeight

Header

Section Two - 30° & 45° Bay Window Installation Guide

16

6. Temporarily Support Unit in Rough Opening

7. Position and Fasten Unit

• Align inside edge of Lower Platform with line scribed on sill plate and align centerline of unit with centerline on sill plate.

• Temporarily fasten Lower Platform to sill plate using three #8 x 3" flat head wood screws.

• Align inside edge of Upper Platform with scribed line on header.

#8 x 3" Flat Head Wood Screw

Lower Platform

• Make sure unit is plumb. Temporarily fasten Upper Platform to header using three #8 x 3" flat head wood screws.

• Check unit for plumb, level and correct operation of operating units. If adjustment is required, remove screws and adjust as needed using shims and jack.

• Refasten unit using #8 x 3" flat head wood screws.

Upper Platform

• Temporarily place jack and 2 x 4 support braces under Lower Platform to prevent unit from tipping out of opening.

2 x 4Support Brace

Jack

LevelProjecting unit must be installed plumb and level regardless of plumbness or levelness of dwelling wall. Failure to do so may result in product damage.

Projecting unit must be supported during installation until fully fastened into opening to prevent tipping. Failure to do so could result in severe personal injury and/or product damage.

Exterior View

Interior View

Metal fasteners and other hardware components may corrode when exposed to preservative treated and fire-retardant treated lumber. Obtain and use the appropriate metal fasteners and hardware as called out by the installation guide to fasten unit to any rough opening made from pressure treated and fire-retardant treated lumber. Failure to use the appropriate materials for the installation may cause a failure resulting in injury, property or product damage.

5. Place Unit in Rough Opening

• Remove cross bracing and skids from unit.• From exterior of dwelling, carefully lift unit into rough opening.

Interior View

Scribed Line

Windows and doors can be heavy. Use safe lifting techniques and a reasonable number of people with enough strength to lift, carry and install window and door products to avoid injury and/or product damage.

Section Two - 30° & 45° Bay Window Installation Guide

17

6" to 8"

• Shim space between header and Upper Platform.• Fasten both Upper and Lower Platforms in rough

opening using #8 x 3" flat head wood screws spaced at 6" to 8" intervals.

9. Apply Blocking or Filler

Header

#8 x 3" FlatHead Wood Screws

Shims

30° or 45° Blocking

8. Secure Unit to Sill Plate and Header

Double Sill Plate

• Cut 30° or 45° blocking or filler pieces to length according to trim-out option desired.

• Insert blocking or filler pieces between side jamb and rough opening of wall. Fasten to rough opening using #8 x 3" flat head wood screws spaced at 10" to 12" intervals.

10. Prepare Flanking Units to be Secured to Side Jambs

FillerPiece

• For Tilt-Wash Flanking Units, Sash and Side Jamb Liners must be removed to secure side jamb of Flanking Units to wall. Proceed with sash removal instructions (A-H), starting on Page 18.

• For Narroline® Flanking Units, Flanking Units will be secured through side jambs without removing Sash or Side Jamb Liner. Proceed to Step 11 on Page 22.

30° or 45° Blocking Filler

#8 x 3" Screws

Side Jambs attached to wall must have blocking or a filler installed vertically between rough opening and side jamb. Failure to do so could result in bowed side jambs and incorrect operation of units.

Support Systems such as Cable Support, Knee Brace, Cantilever Mount, or Post Support can be installed at this time. Refer to Page 14 of this guide. If support system is not installed at this time, jack and temporary support pieces must remain in place.

Method of blocking depends on type of trim-out desired. See "Trim-Out Options" in Step 19 on Page 30 of this guide.• For Modified Trim-Out, cut blocking to fit angle

between rough opening and side jamb.• For Standard Trim-Out, trim filler pieces to match

jamb angle. Inserted filler pieces vertically.

#8 x 3" Screws

Interior View

Interior View

Modified Trim-Out Standard Trim-Out

Left side of illustration depicts Modified Trim-Out. Right side of illustration depicts Standard Trim-Out.

Section Two - 30° & 45° Bay Window Installation Guide

18

DO NOT jerk sash. Glass may break causing injury or sash may be damaged.

B. Tilt the Lower Sash Down

A. Position Lower Sash for Removal

• Raise Lower Sash about 3" from sill.• Slide both Wash Assists down from top of side jambs

until they “snap” in place between Lower Sash and Vinyl Side Jamb Liner.

• Pull in on top rail of sash with firm but gentle force.• While supporting weight of sash, tilt in and down until

sash is at 90 degree position.

C. Remove Lower Sash from Unit

• Depress Shoe Retainer Clip holding Sash Pivot Pin using a Phillips screwdriver.

• This step continued at top of next page.

Vinyl Side Jamb Liner

Wash Assist (one for each side of the sash)

Lower Sash

Shoe

DepressShoe Retainer Clip

Tilt Lower Sash in and down to 90° position.

Sash cannot be removed if it is at an angle less than 90 degrees.

Sash Removal for Tilt-Wash Flanking Units Only

Interior View

Interior View

PhillipsScrewdriver

Sash must be supported at all times when disengaging it from side jamb. Failure to do so may result in personal injury or damage to property or product.

3"

Interior View

Section Two - 30° & 45° Bay Window Installation Guide

19

D. Prepare Upper Sash for Removal

E. Position Upper Sash for Removal

• While holding Upper Sash in position, depress left-hand vinyl Side Jamb Liner and exert firm but gentle inward force on top portion of Upper Sash.

• Tilt Upper Sash in and down until it is at a 90 degree position.

C. Remove Lower Sash from Unit (Continued)

• While Shoe Retainer Clip is depressed, raise Sash corner 2" above Shoe.

• Keep Sash Pivot Pin out of its Shoe while repeating this step for opposite side of Lower Sash.

• When both Sash Pivot Pins are out of their Shoes, lift Lower Sash up and out of window.

• Set Lower Sash safely aside.

• Slide Wash Assists to top of vinyl Side Jamb Liners. • Lower Upper Sash until it is about 5" above sill. • Grasp top right-hand side of Upper Sash. While

depressing vinyl Side Jamb Liner using one hand, gently, but firmly, pull Upper Sash inward until it releases at top.

Wash Assist

Upper Sash

Vinyl Side Jamb Liner

2"

Vinyl Side Jamb Liner

Raise Wash Assists to Top of Both Vinyl Side Jambs

Tilt Upper Sash 90°

Upper Sash

Raise Sash Corner 2" Above Shoe

Shoe

DO NOT leave window opening unattended, especially when small children are present. A fall from the window opening could cause death or serious injury.

DO NOT pull left-hand side of sash out at this time.

Sash cannot be removed if it is at an angle of less than 90 degrees.

Sash Removal for Tilt-Wash Flanking Units Only

Interior View

Interior View

Interior View

Section Two - 30° & 45° Bay Window Installation Guide

20

F. Remove Upper Sash

• Depress Shoe Retaining Clip using a Phillips screwdriver.

• While Shoe Retaining Clip is depressed, raise Sash corner 2" above Shoe.

• Keep Sash Pivot Pin out of its Shoe while repeating this step for opposite side of sash.

• When both Sash Pivot Pins are out of their Shoes, lift sash up and out of frame.

• Set Upper Sash safely aside

2"

Depress Shoe Retainer Clip

Shoe

Shoe

G. Release Tension on Balances

Unlocked Position Locked Position

Omega Spring Brake

• Turn Shoe Balance Cam 90 degrees (unlocked position) using a flat blade screwdriver. Hold screwdriver firmly in Shoe Balance Cam and carefully let shoe rise until tension is released.

• Repeat for other Shoe on same side of unit.• Repeat this step for opposite side.

Shoe Balance Cam

Shoe Balance Cam

Lower Sash Shoe

Upper Sash Shoe

Note: When sash is tilted in, Omega Spring Brake engages side jamb to secure sash.

Continue supporting sash while disengaging it from unit. Sash could fall causing product damage or personal injury.

DO NOT leave window opening unattended, especially when small children are present. A fall from window opening could cause death or serious injury.

Balance Shoes are under high tension. Use a flat blade screwdriver with a long handle so both hands can be used to release balance energy. Suddenly releasing Balance Shoe could damage window unit.

Sash Removal for Tilt-Wash Flanking Units Only

Interior Views

Interior View

Phillips Screwdriver

Flat Blade Screwdriver

Exterior View

Section Two - 30° & 45° Bay Window Installation Guide

21

H. Remove Side Jamb Liner on Jambs Being Attached to Rough Opening

Side Jamb Liner

Lower Sash Track

Flex Side Jamb Liner Toward Interior

Kerf

Upper Sash Track

Sill

• Grasp Side Jamb Liner near sill and place fingers on inside of upper sash track.

• Flex Side Jamb Liner toward interior until outside of liner releases from kerf.

• Work your fingers up Side Jamb Liner until outer edge is completely released.

• Remove Side Jamb Liner and set safely aside.• Repeat for other Side Jamb Liner on opposite side of

rough opening.• Proceed to Step 11.

Sash Removal for Tilt-Wash Flanking Units Only

Interior

11. Secure Flanking Units to Rough Opening

• Predrill a 1/8" hole, 3" deep, through side jambs and 30° or 45° blocking or filler, as shown.

• Fasten side jambs using #10 x 3" flat head wood screws. Make sure screw is fully engaged in blocking or filler piece.

• Proceed to procedures (A-C), on Page 23.

#10 x 3" Flat Head Screws

30° or 45° Blocking Filler

Piece

#10 x 3" Flat Head Screws

Follow step below for your particular unit, Tilt-Wash or Narroline® Double-Hung Window.

Tilt-Wash Flanking Units

Tilt-Wash Flanking UnitsInterior View

Modified Trim-Out Standard Trim-Out

Left side of illustration depicts Modified Trim-Out. Right side of illustration depicts Standard Trim-Out.

30° or 45° Blocking Filler

Metal fasteners and other hardware components may corrode when exposed to preservative treated and fire-retardant treated lumber. Obtain and use the appropriate metal fasteners and hardware as called out by the installation guide to fasten unit to any rough opening made from pressure treated and fire-retardant treated lumber. Failure to use the appropriate materials for the installation may cause a failure resulting in injury, property or product damage.

Section Two - 30° & 45° Bay Window Installation Guide

22

11. Secure Flanking Units to Rough Opening (Continued)

• If existing screws through Side Jamb Liner align with 30° or 45° blocking or filler pieces, remove screws and replace using #10 x 3" flat head wood screws. If screws do not align, follow steps below.

• Predrill 1/8" hole, 3" deep, through Side Jamb Liner and 30° or 45° blocking or filler pieces.

• Fasten side jamb to 30° or 45° blocking or filler pieces using #10 x 3" flat head wood screws. Make sure screw is fully engaged in blocking or filler piece.

• Apply Sill Stops. Application of Sill Stops improves unit performance.

• Proceed to Step 12 on Page 24.

Both Sash Raised Both Sash Lowered

#10 x 3" Flat Head Screws

#10 x 3" Flat Head Screws

Jamb Liner

Jamb Liner

Sill StopSill Stop

When securing Narroline® Double-Hung Windows through Jamb Liner avoid damaging Balance Cords with screws. Damage to Balance Cords will cause improper unit operation.

#10 x 3" Flat Head Screws

30° or 45° Blocking

Filler Piece

Narroline® Flanking Units

Narroline® Flanking Units

Interior View

Interior Exterior

Modified Trim-Out Standard Trim-Out

Left side of illustration depicts Modified Trim-Out. Right side of illustration depicts Standard Trim-Out.

#10 x 3" Flat Head Screws

Section Two - 30° & 45° Bay Window Installation Guide

23

B. Reset Shoe Balance Cam(s)

• Position Lower Sash Shoe by inserting flat blade screwdriver into Shoe Balance Cam and sliding it down until it is about 3" from sill.

• Turn Shoe Balance Cam so cam opening is at top and Shoe is in locked position.

• Position other Lower Sash Shoe in opposite jamb so it is even with Lower Sash Shoe that is locked into position. Turn Shoe Balance Cam so this Shoe is also locked into position.

Upper Sash Shoe

LowerSash Shoe

C. Reinstall Sash

• Perform procedures (A-F), on Pages 18-20, in reverse order to reinstall Sash.

• Firmly seat Sash Pivot Pins in Retaining Clips of Shoes by gently press down on lower corners of Sash.

Balance Shoes are under high tension. Use a flat bladed screwdriver with a long handle so both hands can be used to release balance energy. Suddenly releasing Balance Shoe could damage unit.

Side Jamb Liner and Sash Reinstallation for Tilt-Wash Flanking Units Only

Flat Blade Screwdriver Interior View

A. Reinstall Side Jamb Liner

• Align notch on top of Side Jamb Liner with Head Jamb Liner rib.

• Push inside edge of Side Jamb Liner into wood stop.• Push outside edge of Side Jamb Liner into frame. Side

Jamb Liner may need to be squeezed to get into place.

Wood Stop

Push inside edge of Side Jamb Liner into wood stop.

Push outside edge of Side Jamb Liner into frame.

Side Jamb Frame

Side Jamb Liner

Head Jamb Liner Rib

Push inside edge of Side Jamb Liner into wood stop.

Push outside edge of Side Jamb Liner into frame.

Unlocked Position Locked Position

Omega Spring Brake

Shoe Balance Cam

Shoe Bal-ance Cam

Note: When sash is tilted in, Omega Spring Brake engages side jamb to secure sash.

Section Two - 30° & 45° Bay Window Installation Guide

24

13. Seal Exterior and Apply Side Flashing

• This instruction step depicts one of many options for proper flashing.

• Moisture infiltration problems in any type of building can be reduced by properly flashing and/or sealing around all building openings, including windows and doors. Proper flashing under and around window and door openings can reduce moisture problems, but the performance of any building system depends upon the design and construction of the building system in its entirety, which should address local environment, climate, building codes and product and material limitations. The design and installation of flashing and sealing systems are the responsibility of the architect, contractor, installer, and/or the manufacturer of the building exterior specified for the project.

Unit must be properly flashed and sealed for protection against water and air infiltration. Use non-reflective flashings. Highly reflective flashing tapes can raise the surface temperature of the vinyl to the point where vinyl deformation and product damage may occur.

Exterior View

Flashing Tape

Sill(apply first)

Sides(apply second)

Head(apply third)

12. Window Unit(s) 5'-5" and Wider Only

• Attach 2 x 4 support pieces using #8 x 2" flat head wood screws to Lower Platform to any side of projecting unit 5'-5" and wider.

• Attach front 2 x 4 support piece to installed support piece using #10 x 3" flat head wood screw. Front Support Piece

Lower Platform

#8 x 2" Flat Head Wood Screw

#10 x 3" Flat Head Wood Screw

Support Piece

Projecting Window Unit 5' 5" and WiderAdditional support must be installed on projecting window units if any side of unit is 5'-5" or wider. Failure to do so could result in product damage and/or incorrect operation of units. If no unit(s) are 5'-5" or wider, proceed to Step 13.

Cable Support System OnlyUse template provided in Cable Support System to locate and drill holes through support pieces.

Cross Section Detail

Section Two - 30° & 45° Bay Window Installation Guide

25

14. Seal Interior of Unit

• Insert insulation between frame and rough opening at head and side jambs. Do not overpack or overfill with insulation. Bowed jambs may result.

• Apply a vapor barrier to warm side of Upper and Lower Platforms. For northern climates, apply on interior side. For southern climates, apply on exterior side.

Insulation Around Entire Perimeter of UnitWhen insulating between unit frame and rough

opening, DO NOT over pack batt insulation or over fill with expandable foam. Bowed jambs may result causing performance problems and/or incorrect operation of unit.

Interior View

• Apply sealant to exposed end of Auxiliary Casing.• Apply backer rod and sealant to gap between unit and

exterior sheathing or siding. • Apply flashing tape around perimeter of unit.• Align Side Flashing flush with top of Auxiliary Casing

and bottom of unit. • Push Side Flashing tightly against side jamb and fasten

using 1-1/2" roofing nails.• All exterior siding, or other finish, must have a

recommended 1/4" clearance around unit except at sill in masonry installations.

• Apply sealant around exterior perimeter of unit after siding, or other finish, is applied over Side Flashing.

13. Seal Exterior and Apply Side Flashing (Continued)

SideFlashing Backer

Rod/ Sealant

Apply Flashing Tape on all Sides of Unit

SideFlashing

Auxiliary Casing

SideFlashingBacker Rod

Sealant 1/4" Clearance for Backer Rod and Sealant

Flashing Tape

Exterior View

Section Two - 30° & 45° Bay Window Installation Guide

26

• Trim Fibrex® Cellular Trim Board to fit.• Install a nailer to soffit.• Insert batt insulation.• Secure Fibrex® Cellular Trim Board using corrosion

resistant fasteners.

3-1/2" Fibrex® Cellular Trim Board or wider trim by others

Nailer

Batt Insulation

Fibrex® Cellular Trim Board by Andersen

Fibrex® Cellular Trim Board by Andersen

Fibrex® Cellular Trim Board is available in 3-1/2" width.

• Install Auxiliary Casing for applications having approximately 1-3/16" between unit and soffit.

• Insert batt insulation.

AuxiliaryCasing

Batt Insulation

Auxiliary Casing by Andersen

Auxiliary Casing by Andersen

15. Apply Insulation and Exterior Casing (Exterior Trim Options)

• Install a self-supporting roof structure over top of Auxiliary Casing.

• Insert batt insulation.

AuxiliaryCasing

Roof

Batt Insulation

Air Space

Self-Supporting Roof by Others

Self-Supporting Roof by Others

Section Two - 30° & 45° Bay Window Installation Guide

27

15. Apply Insulation and Exterior Casing (Exterior Trim Options, Continued)

• Attach nailing block to outside edge of Lower Platform using two appropriate length flat head wood screws, as shown.

• Insert batt insulation or 2" rigid foam insulation, as shown.• Cut Fibrex® Cellular Trim Board to length and fasten to nailing

block using 1-1/2" flat head wood screws.• Cut Vinyl Laminate Board soffit to size and fasten to nailing

block using 1-1/2" screws.

5-1/2" Wide Trim by Others

3-1/2" Fibrex® Cellular Trim Board

VinylLaminatedBoard

Vinyl Laminated Board

BattInsulation

2" Rigid Foam Insulation

Fibrex® Cellular Trim Board and Vinyl Laminate Board by Andersen

16. Install Seat Board

• Position Seat Board on top of Lower Platform making sure that finished side is facing up.

• Center Seat Board and make sure interior edge of Seat Board is flush with interior wall.

• Secure with 1-1/2" finishing nails around perimeter of Seat Board 3/8" in from edge. Space nails at 8" intervals.

LowerPlatform

Seat Board

Interior Edge

Interior View

• Fibrex® Cellular Trim Board is available in 3-1/2 width. • Vinyl Laminate Board can be used as soffit for projecting

windows. Vinyl Laminate Board is available in 24" or 48" widths and may be used in conjunction with Rigid Vinyl "J" or "H" Channel by Andersen.

• When using the Cable Support System, access holes must be drilled through Lower Platform soffit and insulation for cable adjustments. Refer to Cable Support System instruction guide.

• OPTION 1 - Seat Board Joined to Lower Platform. Andersen supplied parts. Ideal for new construction and replacement applications. Minimizes drywall repair on replacement installations.

• OPTION 2 - Seat Board Spaced 1/2" above Lower Platform. Spacers are required. Parts supplied by others. Ideal for new construction. Joined Transom Bays or other units requiring Steel Reinforced Joining Posts must use the Spaced Head and Seat Board method to conceal steel end bracket.

OPTION 1 - Joined Method

Fibrex® Cellular Trim Board and Vinyl Laminated Board by Andersen

Option 1 - Joined Method

Nailing Block

Nailing Block

Section Two - 30° & 45° Bay Window Installation Guide

28

16. Install Seat Board (Continued)

Seat Board

Interior View

• For head end of unit, cut Spacer Boards to fit around perimeter of Upper Platform. For Tilt-Wash Double-Hung Windows, 3/4" thick spacer boards are required. For Narroline® Double-Hung Windows, 1/2" thick spacer boards are required. Fasten using #8 x 1-1/4" screws.

• For sill end of unit, cut 2" thick spacer boards to fit around perimeter of Lower Platform. Fasten using #8 x 1-1/4" screws.

• Cut Rigid Foam Insulation to fit inside spacer boards at both head and sill ends of unit. For Tilt-Wash Double-Hung Windows, 3/4" thick insulation is required at head and 2" thick insulation at sill. For Narroline® Double-Hung Windows, 1/2" thick insulation is required at head and 2" thick insulation is at sill. Fasten insulation to Lower and Upper Platforms using appropriate adhesive.

• Position Seat Board tightly against window units making sure finished side is facing outwards.

• Center Seat Board and make sure interior edge of Seat Board is flush with interior wall.

• Secure using 1-1/2" (4d) or 2-1/2" (8d) finishing nails around perimeter of Seat Board 1/2" from edge. Space nails at 8" intervals.

2" Spacer Board

Upper Platform

Lower Platform

1/2" or 3/4" Rigid Foam Insulation

1/2" Rigid Foam Insulation

3/4" Spacer Board for Tilt-Wash Units1/2" SpacerBoard for Narroline® Units

Spacer Board

Spacer Board

Interior View

Interior View

OPTION 2 - Spaced Method

Option 2 - Spaced Method

Head

Sill

Section Two - 30° & 45° Bay Window Installation Guide

29

• Measure distance from Seat Board to Upper Platform Spacer Boards.

• Subtract thickness of Head Board from above measurement. Cut Interior Joining Post Casing to calculated length.

• Position Interior Joining Post Casing and fasten using 1-1/2" finishing nails, 1/2" from edge. Space nails at 8" intervals.

17. Apply Interior Mullion Post Casing

Interior JoiningPost Casing

Interior JoiningPost Casing

• Measure distance from Seat Board to Upper Platform.• Subtract 5/8" from distance and cut Interior Joining

Post Casing to calculated length.• Position Interior Joining Post Casing and fasten using

1-1/2" finishing nails, 1/2" from edge. Space nails at 8" intervals.

OPTION 1 - Joined Method

OPTION 2 - Spaced Method

18. Install Head Board• Slide exterior edge of Head Board on top of Interior

Joining Post Casing making sure finished side of Head Board is facing downward.

• Push Head Board upward against Upper Platform and center. Make sure interior edge of Head Board is flush with interior wall.

• Secure using 1-1/2" (4d) finishing nails around perimeter of Head Board 1/2" from edge. Space nails at 7" intervals.

HeadBoard

Interior Joining Post Casing

Option 1 - Joined Method

Option 2 - Spaced Method

Interior View

Interior View

Interior View

Section Two - 30° & 45° Bay Window Installation Guide

30

19. Trim-Out Options

• For Modified Trim-Out, use standard 3/4" wood trim supplied by others. Ideal for replacement and new construction.

• For Standard Trim-Out, use Adaptor and Extension Jambs available from your Andersen Dealer for 4-9/16", 5-1/4", 6-9/16", and 7-1/8" wall dimensions.

• Fasten using appropriate length finishing nails.

Extension Jamb3/4" Wood Trim

Adaptor

3/4" WoodTrim by Others

3/4" WoodTrim by Others

Filler Piece

30° or 45° Blocking

30° or 45° Blocking

For 3/4" and 1-1/2" Spaced Method OnlyAdaptor and Extension Jambs must be cut to length when applying to spaced Head and Seat Boards.

Adaptor

Modified Trim-Out Standard Trim-Out

Interior View

Modified Trim-Out Standard Trim-Out

Left side of illustrations depict Modified Trim-Out. Right side of illustrations depict Standard Trim-Out.

Interior View

Metal fasteners and other hardware components may corrode when exposed to preservative treated and fire-retardant treated lumber. Obtain and use the appropriate metal fasteners and hardware as called out by the installation guide to fasten unit to any rough opening made from pressure treated and fire-retardant treated lumber. Failure to use the appropriate materials for the installation may cause a failure resulting in injury, property or product damage.

Section Two - 30° & 45° Bay Window Installation Guide

31

Dim. A

Dim. B Dim. C

20. Install Head and Seat Board Trim Pieces

• Measure distance between Interior Joining Post Casings (Dimension A).

• For Modified Trim-Out applications, measure distance between Interior Joining Post Casing and Modified Trim Piece (Dimension B).

• For Standard Trim-Out applications, measure distance between Interior Joining Post Casing and Extension Jamb (Dimension C).

• Cut Head and Seat Board Trim Pieces to appropriate length.

• Rip down three Head and Seat Board Trim Pieces to 5/8" for Tilt-Wash Double-Hung Windows or to 3/8" for Narroline® Double-Hung Windows for application to Head Board.

• Fit Head and Seat Board Trim Pieces into place and fasten using 1-1/4" finishing nails.

Modified Trim PieceTilt-Wash Double-Hung Window - 5/8" Narroline® Double-Hung Window - 3/8" Trim Piece

3/4" Space

2" Space

3/4" Space

1-1/2" Space

Dim. A between Interior Mullion Post Casing

ModifiedTrim Piece

ExtensionJamb

Modified Trim PieceTilt-Wash Double-Hung Window - 9/16"Narroline® Double-Hung Window - 3/8"

Modified Trim PieceTilt-Wash Double-Hung Window - 1-1/16"Narroline® Double-Hung Window - 1-1/16"

Option 1 - Joined Method

Option 2 - Spaced Method

Dim. B For Modified Trim-Out

Dim. C For Standard Trim-Out

Interior View

Interior View

Section Two - 30° & 45° Bay Window Installation Guide

32

Finishing, Cleaning, and Maintenance Instructions

• DO NOT expose unfinished wood to high moisture conditions, excessive heat or humidity. Finish interior wood surfaces immediately after installation. Unfinished wood surfaces will discolor, deteriorate, and/or may bow and split.

• DO NOT stain or paint weatherstrip, silicone beads, vinyl, glass, or hardware.

• Acid solutions used to wash masonry will damage glass, fasteners, hardware, and metal flashing. Follow the acid solution manufacturer's instructions carefully. Protect and/or cover Andersen products during the cleaning process to prevent acid contact. If acid does come in contact with unit, immediately wash all surfaces with clean water.

MAINTENANCEImmediately sand and refinish any interior wood thatbecomes stained or mildewed to prevent further discoloration and/or damage. For further information,contact your local Andersen dealer. Dealers can be found in the Yellow Pages under Windows.

INTERIOR FINISHINGRead and follow finishing manufacturer’s instructions and warnings on each container of finish material for priming, painting, staining, and varnishing.

CLEANINGClean exterior frame, sash members, and insect screens using a mild detergent-and-water solution and a soft cloth or brush. DO NOT use abrasive cleaners or solutions containing corrosive solvents. For persistent dirt or grime, use a nonabrasive cleanser or a mixture of water and alcohol or ammonia.

Guía de instalación y ensamblaje de la ventana panorámica en ángulo de 30º y 45ºpara las ventanas inclinables para limpieza de la serie 400 de Andersen® y las ventanas de guillotina doble de la serie 200 de Narroline®

Las instrucciones son para la construcción nueva de paredes con marcos de madera que cuentan con protección contra la intemperie. Es posible que las instrucciones no sean correctas para todas las instalaciones debido al diseño del edificio, los materiales de construcción o los métodos utilizados, y/o las condiciones de la obra o el edificio. Consulte con un contratista o arquitecto para obtener recomendaciones.Las bridas en la unidad no proporcionarán por sí mismas un flashing ni sellarán la ventana de manera adecuada. Siga estas instrucciones con detenimiento.Si tiene alguna pregunta llame al 1-888-888-7020 de lunes a viernes, de 7 a.m. a 7 p.m., hora del centro, y los sábados de 8 a.m. a 4 p.m., hora del centro. Para obtener más información y/o guías, visite andersenwindows.com.Deje esta guía con el dueño de la construcción.

Gracias por elegir Andersen.

▶▶ Lea▶la▶guía▶por▶completo▶antes▶de▶comenzar▶la▶instalación.▶Lea▶todas▶las▶advertencias▶y▶precauciones▶durante▶la▶instalación▶de▶la▶unidad.▶

Tenga cuidado al trabajar en lugares elevados y cerca de las aberturas de la unidad. Siga las instrucciones del fabricante para el uso de escaleras y/o andamios. De no hacerlo así, podrían producirse lesiones o la muerte.

Siga las instrucciones del fabricante para el uso de herramientas eléctricas o manuales. Utilice siempre lentes de seguridad. De no hacerlo así, podrían producirse lesiones y/o daños al producto.

Las ventanas y puertas pueden ser pesadas. Utilice técnicas seguras de levantamiento de peso y una cantidad razonable de personas con suficiente fuerza para levantar, cargar e instalar las puertas y ventanas, a fin de evitar lesiones y/o daños al producto.

“Andersen” y las demás marcas que aparezcan son marcas registradas de Andersen Corporation. ©1996-2010 Andersen Corporation. Todos los derechos reservados. 0005133 BD Revised 10/27/10

A menos que se solicite específicamente, las ventanas y puertas Andersen no están equipadas con vidrios de seguridad, y si se rompen, se pueden fragmentar y causar lesiones. Muchas leyes y códigos de construcción exigen vidrios de seguridad en lugares adyacentes a puertas o cerca de éstas. Las ventanas Andersen se encuentran disponibles con vidrios de seguridad que pueden reducir la posibilidad de lesiones cuando se rompen. Para obtener información sobre el vidrio de seguridad, consulte a su distribuidor de Andersen local.

• Los flashings para cabecera y las bridas de instalación Andersen® NO reemplazan el flashing estándar de la ventana y puerta. La unidad debe estar instalada con flashing y sellada con sellador de manera adecuada para protegerla contra la filtración de agua y aire. Use flashing no reflectante. Las cintas de flashing altamente reflectante pueden aumentar la temperatura de la superficie de vinilo hasta el punto en que se puede producir deformación del vinilo y dañar el producto.

• No aplique ningún tipo de películas a los vidrios. Las condiciones de tensión térmica pueden ocasionar daños en el vidrio.

• El uso de materiales aislantes móviles, como cubiertas de ventanas, persianas y otros dispositivos similares pueden dañar el vidrio y/o el vinilo. Además, el exceso de condensación puede deteriorar las puertas y ventanas.

Sección uno - Guía de ensamblaje de la ventana panorámica en ángulo de 30° y 45°

2

Para unidades de antepecho unido y unidades centrales de 2 de ancho solamente

Para las instalaciones de las unidades de antepecho unido y/o unidades centrales de 2 de ancho, es necesario utilizar material de unión adicional para unirlas. Consulte la sección Diseños de combinación en la Guía de productos para profesionales Andersen® para asegurarse de que utilice el material de unión adecuado y que las combinaciones funcionarán de manera correcta y de conformidad con los códigos de construcción locales. Consulte con un arquitecto o contratista. De no hacerlo así, podrían producirse lesiones y/o daños al producto.

Piezas necesarias• Unidad(es) central(es) (A)• Unidades laterales (B)• Montantes de unión

de 30º ó 45º (C)• Plataforma superior e

inferior (D)• Cabecera y bases (E)• Sujetadores del montante de

unión (F)• Sujetadores de unión (G)• Moldura del montante de unión

interior de 30º ó 45º (H)• Flashing lateral (I)• Adaptador de 30º ó 45º (J)• Aislante de espuma rígida (K)

Herramientas y suministros• Lentes de seguridad• Martillo• Destornillador de punta plana• Destornillador Phillips• Nivel• Escuadra de carpintero• Escuadra combinada• Cinta métrica• Abrazaderas• Cuñas (impermeables)• Pistola para calafatear• Sellador• Cinta de flashing• Lápiz• Palanca pequeña• Punzón• Cuchilla de uso general afilada• Paños suaves• Alcohol isopropílico• Soporte regulable de altura

y soporte• Tornillos de cabeza plana

para madera No 8 x 1-1/4" No 8 x 1-1/2" No 8 x 2" No 8 x 2-1/2" No 8 x 3" No 8 x 5-1/2"• Taladro/destornillador• Broca para taladro de 3/8"• Broca para taladro de 1/8"• Broca para taladro de 3/32"• Clavos de acabado de 1-1/4"• Clavos de acabado de 2-1/2"• Grapas o clavos de 3/4"• Bases espaciadoras de 1-3/8"• Material para calzos de

2 x 4• Refuerzo en cruz de 1 x 4

Identificación del componente

Accesorios opcionales• Jambas de extensión (L)• Cabecera y bases

Contramarco interior• Moldura auxiliar• Sistema de soporte de cables• Tope de riel inferior

Perma-Shield® Narroline®

• Base del contramarco de madera celular Fibrex®

Parte interior hacia arriba

Sección uno - Ensamblaje de la ventana panorámica en ángulo de 30° y 45°

L

J

I

B

C

D

K

HA

E K

H

FG C

B

L

I

J

Los sujetadores y otros herrajes de metal pueden corroerse cuando quedan expuestos a madera tratada con retardador de fuego y con preservante. Obtenga y utilice los sujetadores e instrumentos metálicos apropiados, como se indica en la guía de instalación, para sujetar la unidad a cualquier abertura no acabada de madera tratada con retardador de fuego y a presión. Si no utiliza los materiales apropiados para la instalación, se pueden producir lesiones o daños al producto o a la propiedad.

Sección uno - Guía de ensamblaje de la ventana panorámica en ángulo de 30° y 45°

3

Para unidades de antepecho unido solamente• La unión de los antepechos de las

ventanas debe realizarse antes de comenzar con el ensamblaje de la ventana panorámica. Una los antepechos de acuerdo con las instrucciones que se encuentran en el juego de unión de antepecho de guillotina doble.

• Las unidades que sobresalen con unidades de antepecho adosadas no deben exceder los 8' 2-1/4" de altura.

Para unidades de antepecho unido y unidades centrales de 2 de ancho solamente• Determine el tipo de unión requerido según la sección Diseños de combinación de La Guía de Productos para

Profesionales Andersen®.• Determine la capacidad de rendimiento de la unidad ante la presión del viento. Una las unidades según la tabla

de presión de viento correspondiente a cada diseño que se encuentra en la Guía para profesionales Andersen®.• Una las unidades según la guía de instrucciones de juegos de materiales de unión correspondiente. • Los juegos de materiales de unión que se encuentran disponibles incluyen un juego de unión no reforzada para

unidades inclinables para limpieza, un juego de unión no reforzada para unidades Narroline®, y un juego de unión no reforzada con antepecho adosado.

Para unidades centrales de 2 de ancho solamente• Las unidades centrales deben unirse antes de

continuar con el ensamblaje de la unidad panorámica.

• las instrucciones de unión cuando utilice dos ventanas inclinables para limpieza o dos ventanas Narroline® en lugar de una ventana panorámica de guillotina doble.

Sección uno - Guía de ensamblaje de la ventana panorámica en ángulo de 30° y 45°

4

Coloque la pieza de relleno de cabecera en la cabecera de las ventanas inclinables para limpieza y panorámicas de guillotina doble al ras con la jamba de cabecera con grapas o clavos de 1" colocados a una distancia de 6" entre sí (las grapas y los clavos no están incluidos en el juego).

Pieza del relleno de cabecera

Ventana panorámica de guillotina doble o ventana inclinable para limpieza solamente

Jamba de cabecera

Grapas o clavos de 1"

Para unidades inclinables para limpieza y panorámicas de guillotina doble solamente

Parte interior hacia arriba

1. Prepare las unidades para ensamblarlas

• Cuando prepare las unidades para ensamblarlas, asegúrese de que las unidades estén ubicadas correctamente y en la dirección adecuada.

• La pared debe ser de 4-9/16" a 7-1/8" para las plataformas, las bases de cabecera y las bases en existencia.

CabeceraUnidad(es) central(es) Unidad lateralUnidad lateral

Riel inferior

• Retire las ventanas del paquete con cuidado y coloque la parte interior hacia arriba sobre una superficie de trabajo limpia y plana.

• Retire los bloques de embalaje de espuma.• Para extraer las bridas de instalación laterales, empuje hacia

afuera desde los laterales de todas las unidades.• Con una cuchilla de uso general afilada, recorte la brida de

instalación de cabecera y del riel inferior al ras con las jambas laterales de las unidades.

• Coloque las unidades en la posición adecuada para ensamblarlas.

Recorte las bridas de instalación de cabecera al ras con las jambas laterales

Retire las bridas de instalación laterales

Parte interior hacia arriba

Jamba lateral

Recorte las bridas de instalación del riel inferior al ras con la jamba lateral

2. Ajuste las unidades laterales a la(s) unidad(es) central(es)

Unidad(es) central(es) Unidad lateralUnidad lateral

Parte interior hacia arriba

• Deslice las unidades al mismo tiempo y alinee la cabecera y el riel inferior de las unidades laterales con la(s) unidad(es) central(es).

Sección uno - Guía de ensamblaje de la ventana panorámica en ángulo de 30° y 45°

5

2. Ajuste las unidades laterales a la(s) unidad(es) central(es) (continuación)

Ventana panorámica de guillotina doble a ventana de guillotina doble Narroline®

Ventana inclinable para limpieza a ventana inclinable para limpiezaVentana inclinable para limpieza

a ventana panorámica de guillotina doble

Ventana Narroline® a ventana de guillotina doble Narroline

Sujetador de unión para ventanas inclinables para limpieza

Sujetador de unión para ventanas Narroline®

• Coloque los sujetadores de unión sobre las jambas laterales a 4" de los extremos de las unidades. Deje un espacio de igual medida entre los dos sujetadores restantes en las unidades. Para las unidades de antepecho unido, se necesita un juego de sujetadores de unión adicional.

• Golpee levemente los sujetadores de unión hasta colocarlos en su lugar. Pretaladre orificios de 1-1/4" de profundidad con una broca para taladro de 3/32" y ajuste los sujetadores de unión con tornillos No. 8 x 1-1/4".

Sujetador de unión

Para unidades laterales Narroline® solamenteColoque cuñas temporales debajo del borde exterior de las unidades laterales hasta que los sujetadores de unión estén ajustados.

Parte interior hacia arriba

• Determine, conforme a los detalles que se brindan a continuación, el tipo de sujetador de unión que debe colocar según las unidades que se unirán.

• Coloque el lado no acabado de las plataformas hacia arriba sobre la superficie de trabajo.

• Mida la longitud de la plataforma a lo largo del borde interior. Haga una marca con el lápiz en el centro de la plataforma.

• Marque una línea central en el ancho de la plataforma con una escuadra de carpintero.

• Repita este paso para la otra plataforma.

• Levante la plataforma superior con el lado uniforme hacia arriba (lado opuesto de la marca de la línea central).

• Trace dos líneas de 3" y 1-1/4" hacia adentro y a lo largo de toda la longitud del borde exterior de la plataforma superior con una escuadra combinada.

3. Prepare las plataformas

Línea trazada de 1-1/4"

Línea trazada de 3"

Marca de la línea central

Plataforma superior

Plataforma superior

Escuadra combinada

Escuadra de carpintero

Lápiz

Sujetador de unión para ventanas Narroline®

Plataforma superior/inferior

Lado no acabado

Lado uniforme

Borde interior

Borde exterior

Sección uno - Guía de ensamblaje de la ventana panorámica en ángulo de 30° y 45°

6

4. Determine y marque la línea central en la unidad

• Para la unidad central simple, mida el ancho de la unidad central a lo largo del marco. Haga una marca con el lápiz en el centro de la unidad sobre el marco, como se muestra. Repita este paso en el otro extremo de la unidad central.

• Para la unidad central de 2 de ancho, haga una marca con el lápiz en el centro del montante de unión del medio o en el área de unión. Repita este paso en el otro extremo del montante de unióndel medio.

Marque el centro

Unidad central simple

5. Coloque la plataforma inferior y ajústela temporalmente

• Coloque la plataforma inferior con la línea central hacia adentro, contra la brida de instalación de la(s) unidad(es) central(es).

• Alinee la línea central de la plataforma inferior con la marca central de la(s) unidad(es) central(es).

• Perfore orificios de no más de 1-1/2" de profundidad con una broca de 3/32"cada 4" ó 6" sobre la línea trazada.

• Ajuste temporalmente la plataforma inferior con dos tornillos de cabeza plana para madera No. 8 x 1-1/2" ubicados sobre la línea trazada.

Riel inferior

Cabecera

Plataforma inferior

Brida de instalación

La cantidad de unidades centrales determinará la ubicación de la línea central en la unidad. Siga el procedimiento a continuación según la cantidad de unidades centrales en la instalación.

Para unidades centrales Narroline® solamenteLas unidades Narroline cuentan con burletes flexibles en el riel inferior en lugar de una brida de instalación rígida. El burlete flexible no es suficiente para sostener la plataforma inferior cuando se encuentra ubicada. Utilice un espaciador de 1-3/8" de espesor debajo del burlete flexible para ayudar a sostener la plataforma inferior.

Parte interior hacia arriba

Parte interior hacia arriba

Lápiz

• Levante la plataforma inferior con el lado uniforme hacia arriba (lado opuesto de la marca de la línea central).

• Trace una línea de 3/4" hacia adentro y a lo largo de toda la longitud del borde exterior de la plataforma inferior con una escuadra combinada.

Plataforma inferior

3. Prepare las plataformas (continuación)

Plataforma inferior

Línea trazada de 3/4"Escuadra combinada

Riel inferior

Lápiz

Cabecera

Lado uniforme

Lado uniforme

Sección uno - Guía de ensamblaje de la ventana panorámica en ángulo de 30° y 45°

7

6. Sujete la plataforma inferior a la(s) unidad(es) central(es)• Ajuste la plataforma inferior a la(s) unidad(es)

central(es) a lo largo de la línea trazada con tornillos de cabeza plana para madera No. 8 x 1-1/2" en los orificios pretaladrados.

Plataforma inferior

Tornillo No. 8 x 1-1/2"

Línea trazada

Plataforma inferior

Riel inferiorParte interior hacia arriba

4" a 6"

3/4"Detalle de la sección transversal

• Ajuste la plataforma superior a la(s) unidad(es) central(es) a lo largo de la líneas trazadas con tornillos de cabeza plana para madera No. 8 x 1-1/2". Coloque los tornillos a una distancia de 6" a 8" entre sí.

Cabecera

Riel inferior

Plataforma superior

Tornillo No. 8 x 1-1/2"

7. Sujete la plataforma superior a la(s) unidad(es) central(es)

Plataforma superior

NO coloque los tornillos en las áreas del compensador resaltadas en color negro.

Unidad lateral

Unidad lateral

NO coloque los tornillos en las áreas del compensador resaltadas en color negro.

Sólo para ventanas de guillotina doble Narroline®

NO ajuste la plataforma superior a la cabecera de las unidades Narroline® dentro de las 8" de cualquiera de las jambas laterales. El compensador se dañará.

Parte interior hacia arribaLíneas trazadas

6" a 8"

3"

1-1/4"

Detalle de la sección transversal

Ventana panorámica de guillotina doble como unidad central

Unidad(es) Narroline como unidad central

Unidad lateral

Unidad lateral

8"

8" 8"

8"

8"

8" 8"

8"

8" 8" 8" 8"

Sección uno - Guía de ensamblaje de la ventana panorámica en ángulo de 30° y 45°

8

9. Sujete las plataformas a las unidades laterales

Unidad lateral Unidad lateralCabecera

Plataforma superior

Plataforma superior

Sólo para ventanas de guillotina doble Narroline®

NO ajuste la plataforma superior a la cabecera de las unidades Narroline® dentro de las 8" de cualquiera de las jambas laterales. El compensador se dañará. Consulte las precauciones que debe tomar para ubicar el compensador en el paso 7.

• Levante la unidad lateral en su posición y ajústela temporalmente a la plataforma superior con un tornillo de cabeza plana para madera de 1-1/2". Coloque el tornillo sobre las líneas trazadas en la plataforma superior.

• Repita este procedimiento en la plataforma inferior.• Repita este procedimiento en la unidad lateral

opuesta.• Verifique que la cabecera y la base se encuentren